MAINTENANCE

OPERATOR MANUAL

45

P20PS

46

OM-P20PS2019001-EN

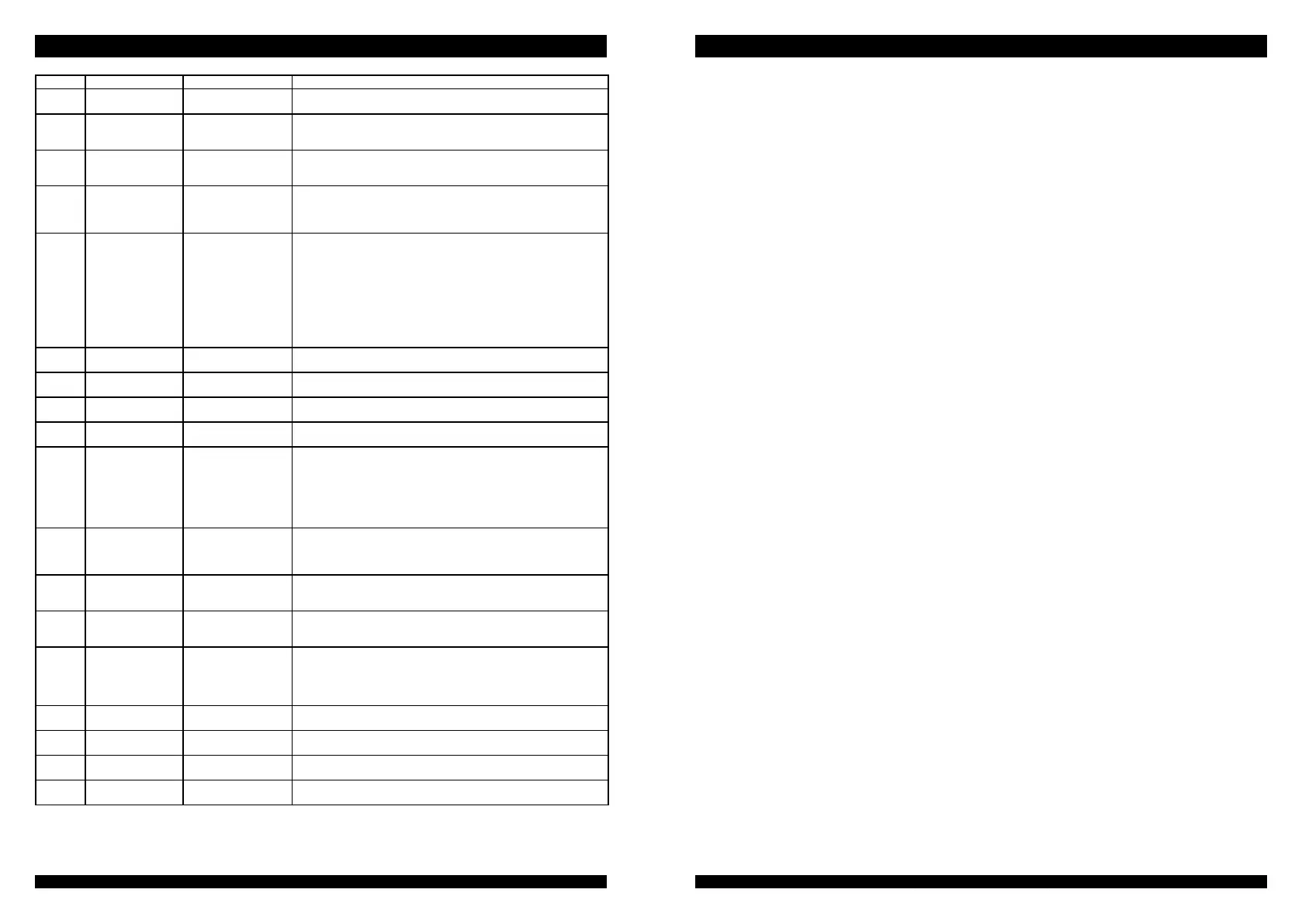

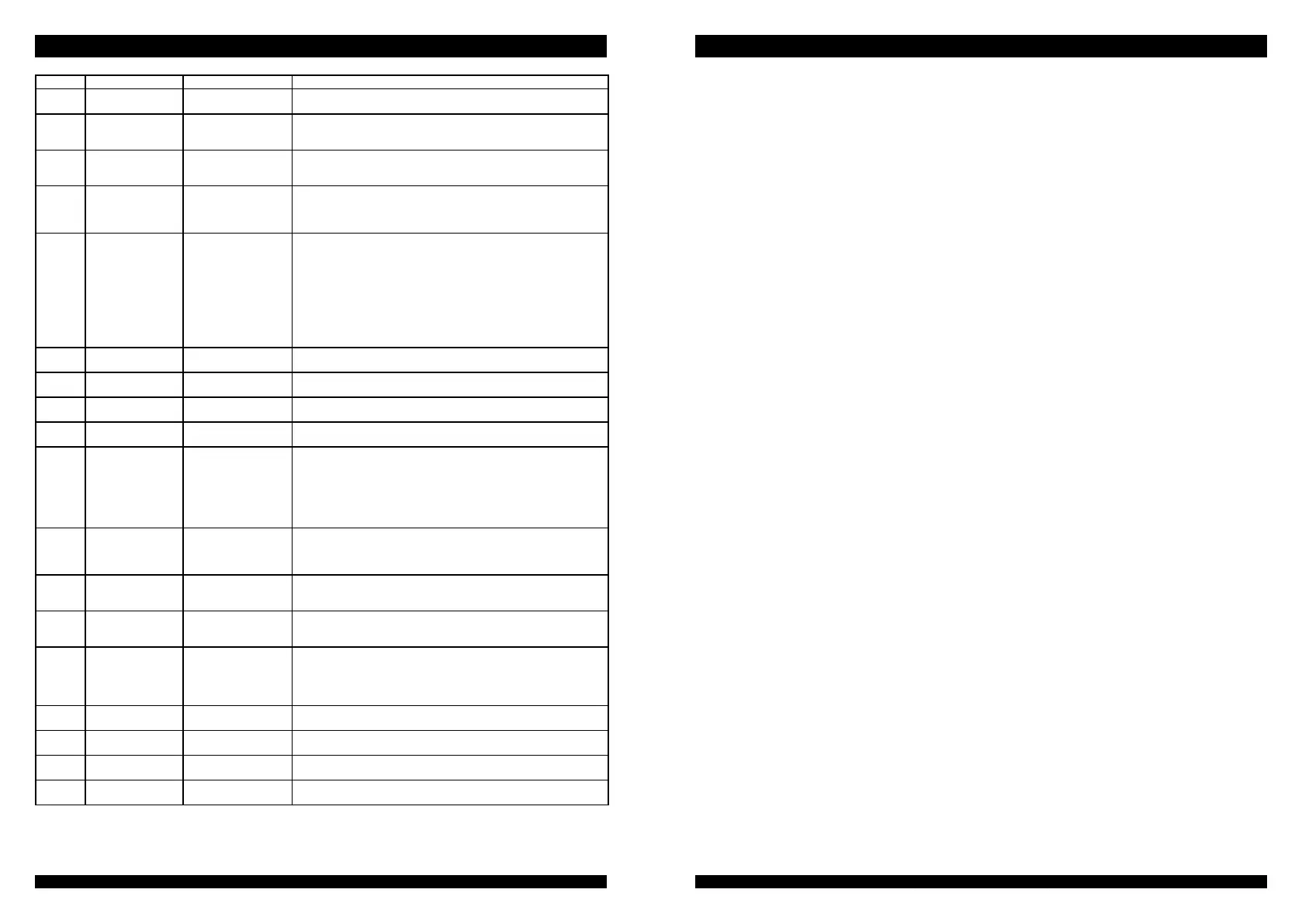

06A29 ANT. MISSING

06A0 WAITING DATA Waiting for data 1.Check if the CAN BUS communication line is connected properly;

2.Check if the bit rate of the communication is consistent;

06A0 EPS NOT ALIGNED Waiting for data

1.Check if the zero proximity switch is installed properly;

2.Check if the zero proximity switch is correctly selected;

3.Check if the output data of zero proximity switch is correct;

06A0 WAITING FOR TRAC Waiting for towing controller

1.Check if the CAN BUS communication line is connected properly;

2.Check if the connection line of interlock switch is correct;

3.If the interlock switch is controlled by tiller, set TILLER SEITCH as HANDLE;

06A0 KEYOFF Key switch voltage low

1.Check if the key switch voltage receives a low voltage pulse when turning on the external

load;

2.Check if B+ and B- are rmly connected to the controller;

3.If the fault is reported every time the key is turned on, replace the controller;

06A25 ENCODER ERROR Encoder fault

The controller detects that two successive speed readings of the encoder differs greatly from

each other. A normal encoder in the system cannot change speed readings greatly within a

very short time. Hence, a possible cause for the symptom is that the wires of one or more

encoders are worn or broken. Check the mechanical and electrical parts of the encoder.

Another possible for the symptom is electromagnetic interference from the sensor bearing. If

the symptom is not due to the two causes, replace the controller.

Note: Sometimes manual operations may also cause this fault indicating on the controller. In

these cases, it is required to turn off power supply and start the forklift again. For example:

1.The forklift suddenly collides with an obstacle so that it is incapable of travelling;

2.The driver applies the brake sharply while the forklift is travelling at a high speed.

06A7 Q LINE SENSOR KO Step motor Q LINE voltage

failure

1.Check if the stepper motor cable is intact;

2.Resistance between Q line and B- too small (Approaching 30Ω);

06A6 D LINE SENSOR KO Step motor D LINE voltage

failure

1.Check if the stepper motor cable is intact;

2.Resistance between D line and B- too small (Approaching 30Ω);

06A27 GAIN EEPROM KO EEPROM memory current

value is different

Replace the controller;

06A11 DATA ACQUISITION Data collection Activation of this fault indicates data acquisition is under way. Wait data acquisition is

completed.

06A24 MICRO SLAVE KO Main and slave microprocessor

detection does not match

1.When using a stepper motor, the direction of the stepper motor detected by the main

microprocessor and slave microprocessor is inconsistent;

2.In the closed-loop control system, the direction of the stepper motor detected by the main

contactor is incorrect and is inconsistent with the direction of the stepper motor detected by

the slave contactor;

3.The main contactor did not detect the steering limit position, but it was detected by the

slave contactor;

06A28 CAN BUS KO CAN BUS communication fault

1.Check if the CAN BUS communication line is connected properly;

2.Check if the bit rate of the communication is consistent;

3.Check if the CAN communication is open;

4.Check if the CAN communication loop resistance is 60Ω.

06A22 S.P OUT OF RANGE Output steering potentiometer

out of range

If a single potentiometer, such as CPOC1 end, is out of range 0.8V-4.2V, it will alarm. When

the dual potentiometer is selected, the sum of the two sliding ends (CPOC1+CPOC2) is out

of the range of 4.4V-5.5V and it will alarm. Check the connection of potentiometer.

06A23 F.B OUT OF RANGE Feedback of steering motor

encoder out of range

Feedback potentiometer (CPOT connecting to CNB#6) has fault, it will alarm. The range of

CPOT is out of 0.3V-4.7V, it will alarm. Check if the steering motor encoder is connected

correctly and whether there is a open circuit;

06A21 MICRO SLAVE The information on the

status bus between the main

microprocessor and slave

microprocessor is frozen to the

OXFF value.

The controller should be replaced;

06A19 KM OPEN Main contactor of slave

contactor open

Slave contactor monitors the open of safety contactor of main contactor, and the controller

needs to be replaced;

06A18 KS OPEN Safety contactor of slave

contactor open

Main contactor monitors the open of safety contactor of slave contactor, and the controller

needs to be replaced;

06A17 KM CLOSED Safety contactor of main

contactor closed in advance

Slave contactor monitors the advanced close of safety contactor of main contactor, and the

controller needs to be replaced;

06A16 KS CLOSED Safety contactor of slave

contactor closed in advance

Main contactor monitors the advanced close of safety contactor of slave contactor, and the

controller needs to be replaced;

Loading...

Loading...