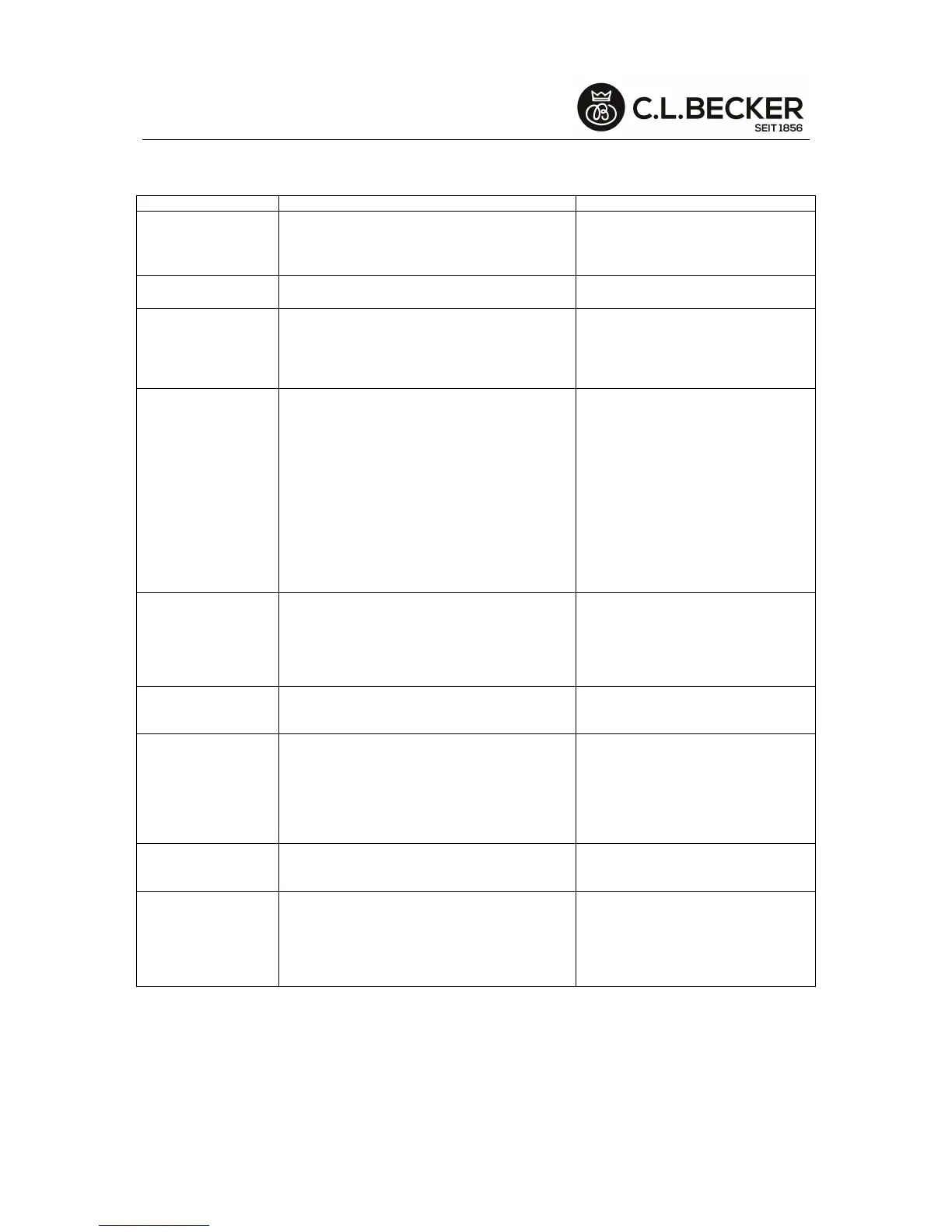

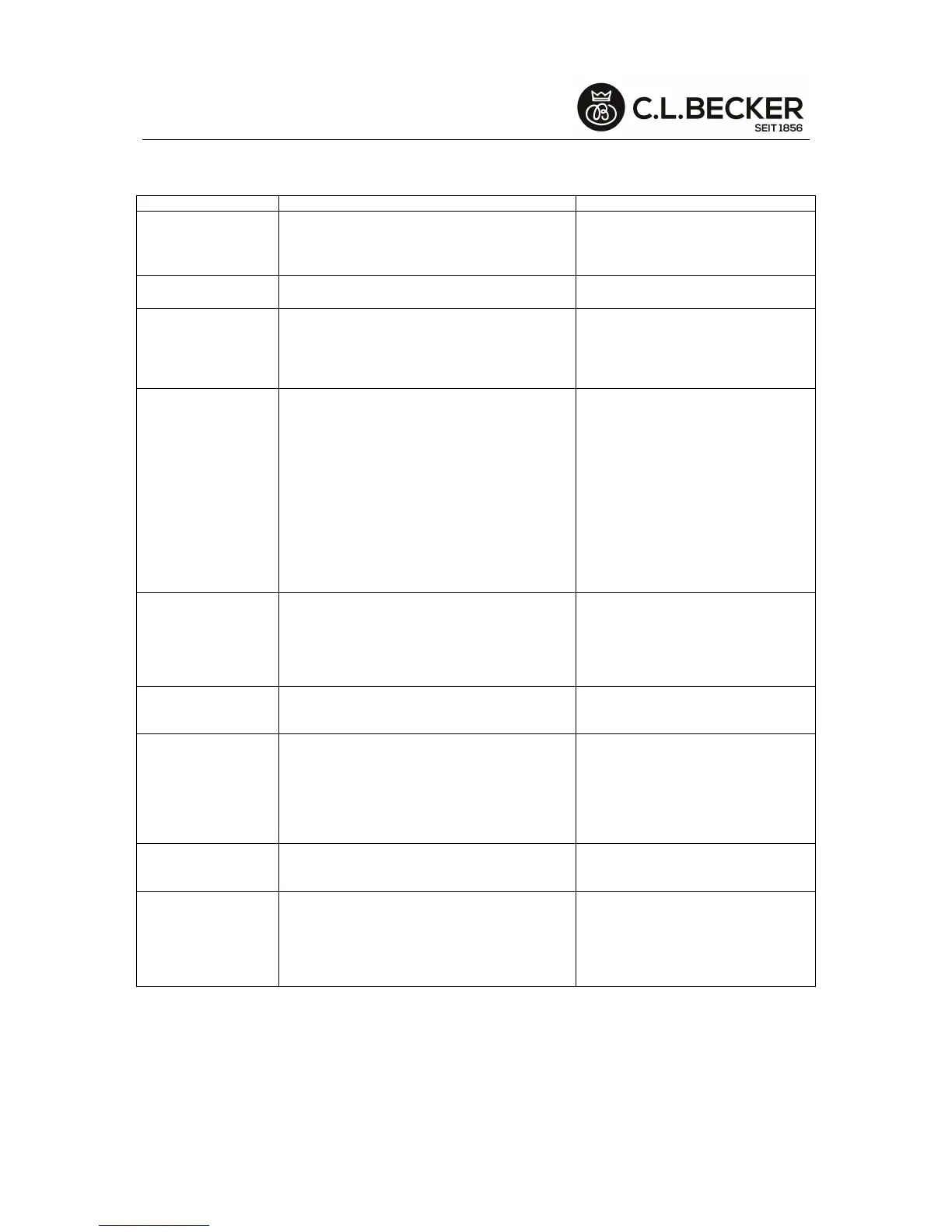

11 Troubleshooting

Problem Cause Corrective action

Device doesn`t start

• defective fuse

• defective plug

• motor protection triggered

• change

• change

• press red button firmly, than start

again

Motor protection

switch turns off

• consumption in the engine is too high

• check electrical system

• reduce pump pressure to maximum

During start of pump

is no audible noise

• The pump does not fill up and runs empty

• in the suction line isn’t any water

• The valves are blocked

• The pressure pipe is closed, thereby pre-

venting the escape of air located in the pump

• check booster pump, if necessary

refill

• check and clean

• open pressure pipe

*)

Irregular pulsations of

the pipes

• air intake or insufficient suction of liquid

• elbows and fittings reduce the suction flow

• The suction filter is dirty or too small

• pressure or flow rate of the (optionally

installed) Booster pumps are inadequate

• The pressure of the water column is

insufficient, the pump is not filled with water,

the pressure pipe is closed during intake and

/ or a valve is stuck

• valves or pressure seals are worn and / or

there are problems when driving

• The pressure regulator valve does not work

properly

• check and repair

The output of the

pump does not match

the specifications on

the nameplate, the

pump is very noisy

• suction capacity insufficient or lower speeds

than on the nameplate

• worn out valves

• cavity formation due to small suction pipes

and / or filters, insufficient capacity, high

water temperature, clogged

• check

• check and change

Insufficient pump

pressure

• The nozzle is larger than needed or worn.

• The pressure-control valves do not function

properly and / or the valves are worn out

• change

• change

Overheating of the

pump

• Excessive pump pressure and / or engine

speed exceeds the specifications on the

nameplate

• Oil level in the pump housing or used oils do

not comply with requirements

• Excessive belt tension, clutch or drive are not

aligned

• check

• check and replace if necessary

• check

Bypass switches

during operation,

pressure increases

• wrong nozzle mounted

• dirt in the injector

• check and replace

• remove and clean

*)

Injector doesn’t suck

chemicals

• ball stuck (soap residue)

• high pressure hose is too long

• low pressure nozzle at double-pipe is locked /

blocked (wrong nozzle)

• injector nozzle worn out

• disconnect chemical hose, solve

ball with a pointed object

• use a shorter high pressure hose

• open, clean, replace if necessary

• replace

*) Let repairs and settings be carried out from your C. L. Becker GmbH customer service.

If your actions do not resolve the problem, contact your C. L. Becker GmbH customer service.

BA HHPC-170/21 60Hz englisch

Art.Nr. 02505004/60/BECKER/ENG

Stand 05/2013 Seite 19 von 23

Loading...

Loading...