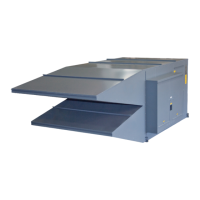

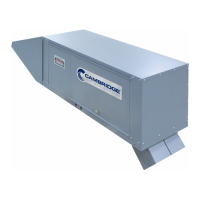

M-SERIES

DRAW THRU

DIRECT GAS-FIRED

MAKE-UP AIR HEATERS

TECHNICAL MANUAL

M-TM2-0120

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating, and maintenance instructions

thoroughly before installing or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers in

the vicinity of this appliance is hazardous.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

Made in the USA

90.1

ASHRAE

ASHRAE

COMPLIANT

COMPLIANT

®