Cambridge Engineering, Inc. 28 S-Series Technical Manual

mWARNING:

Any gas leak detected must be repaired before unit

is placed into service.

e. Turn the blower and burner service switches to the

“OFF” position.

f. Reconnect the wire to terminal #3 on the amplifier

g. When performing a start-up proceed to the next

step, otherwise perform Final Heater Preparation

(page 29).

10. GAS VALVE LEAK CHECK

All heaters should be evaluated for the gas tightness

of the gas valve seat. Heaters rated over 400,000

Btu/hr are equipped with a leak test facility to assist

in checking this seal. A momentary switch and a

gas port for measuring pressure between the valves

are provided for leak testing. Refer to the Individual

Component Description Section for more information

regarding the leak test switch (page 70).

a. Connect a 0-10" WC manometer to the 1/8" NPT

fitting on the manual shut-off valve located just

prior to the burner and verify the manometer is

properly zeroed.

b. On single redundant valve applications (heaters

rated less than or equal to 400,000 Btu/hr), close

the manual burner shut-off valve and wait 30 sec-

onds to read the manometer. If the reading is great-

er than 0" WC, replace the gas valve and retest. If

the reading is 0" WC, remove the manometer and

reinstall the pipe plug.

On separate redundant valve applications, close

the manual burner shut-off valve, hold the momentary

leak test switch in the closed position and wait 30 sec-

onds to read the manometer. If the reading is great-

er than 0" WC, refer to the Maintenance Instruction

Section for information on Gas Valve Cleaning for

the safety shut-off gas valve closest (SSV) to the

burner and retest. If the reading is 0" WC, remove

the manometer and reinstall the pipe plug.

To check the gas tightness of the SOV shut-off

valve in the gas train, connect the manometer to the

leak test port between the valves and wait 30 sec-

onds to read the manometer. If the reading is greater

than 0" WC, refer to the Maintenance Instruction

Section for information on Gas Valve Cleaning

for the shut-off gas valve farthest from the burner

(SOV) and retest. If the reading is 0" WC, remove

the manometer and reinstall the pipe plug.

11. FINAL HEATER PREPARATION

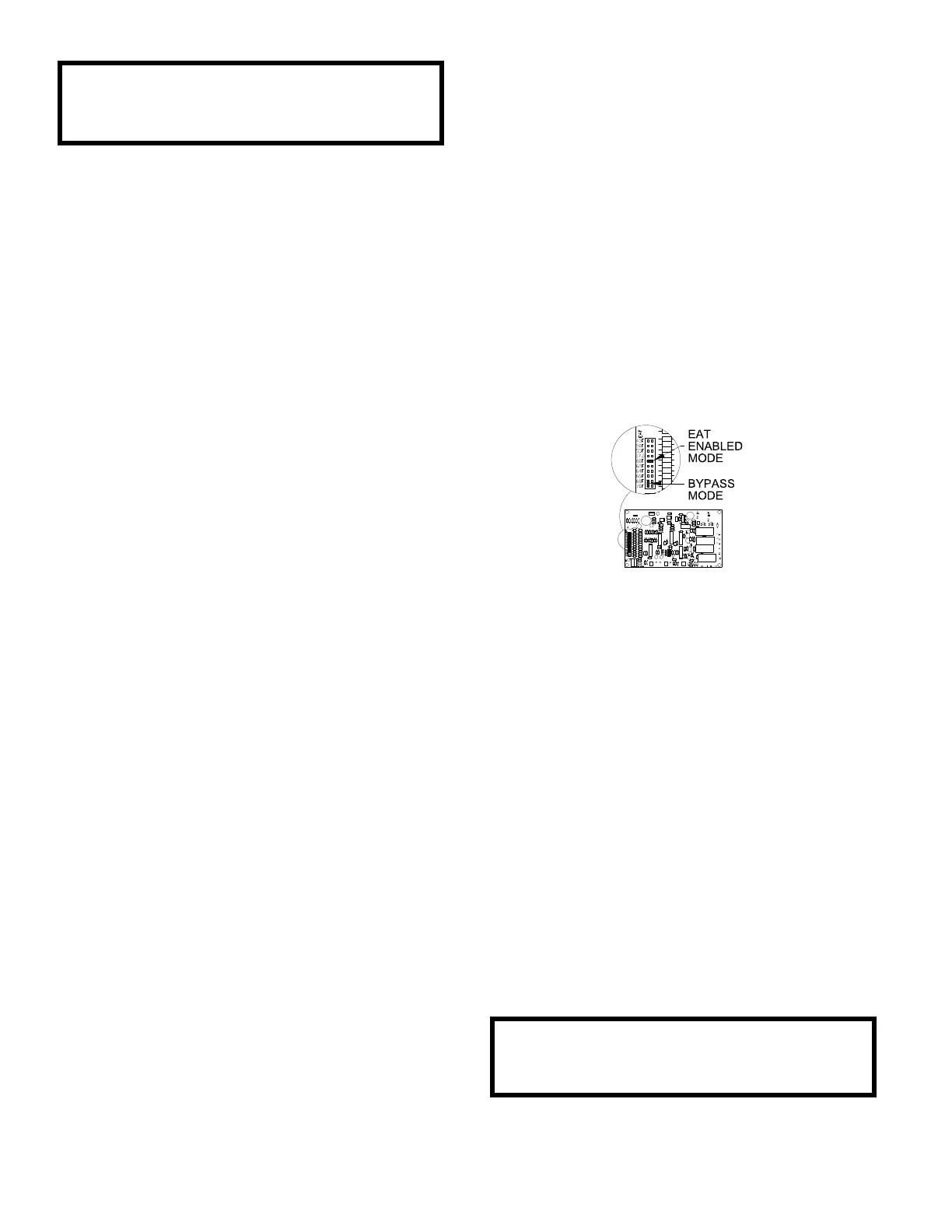

a. On EDSM and EDSM/TP control systems, if the

ambient temperature is at or above the Entering

Air Thermostat (EAT) set point and the Remote

Control Station Check has not been performed,

then the EAT must be adjusted in the heater. Note

the set point position and pull the jumper off the

temperature set point (EAT Enabled Mode) and

reinstall it sideways on the terminal block (Bypass

Mode) as shown in Figure 1. Refer to the Individual

Component Description section for additional infor-

mation.

Figure 1

b. Ensure the discharge temperature setting(s)

comply(ies) with the application specifications.

c. If inlet ducting is utilized, determine the time

required to purge it with four (4) air changes and

select a pre-purge time that will accommodate this

time. Refer to Individual Component Description

for additional information on the multi-functional

PC board.

d. Perform a visual inspection of all wiring and gas

valve plugs to ensure they have been properly

replaced.

e. Return the Technical Manual and the Wiring

Diagram to the manual holder.

f. Turn the blower and burner service switches to the

“REMOTE” position.

mWARNING:

All safety controls must be returned to normal

operating conditions.

Loading...

Loading...