16

After the control has been set up properly (the jumpers set to the desired positions and the

wiring completed), the start-up procedure can begin. If AC power has been properly brought

to the control, the “ON” and the “STOP” indicators will be lighted. Before initially starting, be

sure the main potentiometer is set to approximately 15% rotation. To start the control, move

the Run-Jog/Stop Switch to the “Run” position and release. The “Stop” indicator should extin-

guish and the motor should rotate as the potentiometer knob is rotated clockwise.

Note: If the motor rotates in the wrong direction, it will be necessary to disconnect the

main AC power and reverse the armature wires. To stop the motor, move the Run-

Jog/Stop Switch to the Stop position. If power is lost the control will not restart,

unless the Run- Jog/Stop Switch is moved to the “Run” position.

X. TRIMPOT ADJUSTMENTS

The control contains trimpots which have been factory adjusted for most applications.

Figures 2A and 2B, on pages 4 and 5, illustrate the location of the trimpots and their approx-

imate adjustment positions. Some applications may require readjustment of the trimpots in

order to tailor the control to exact requirements. (See table 2, on page 4, for range and fac-

tory setting of trimpots.) Readjust trimpots as follows:

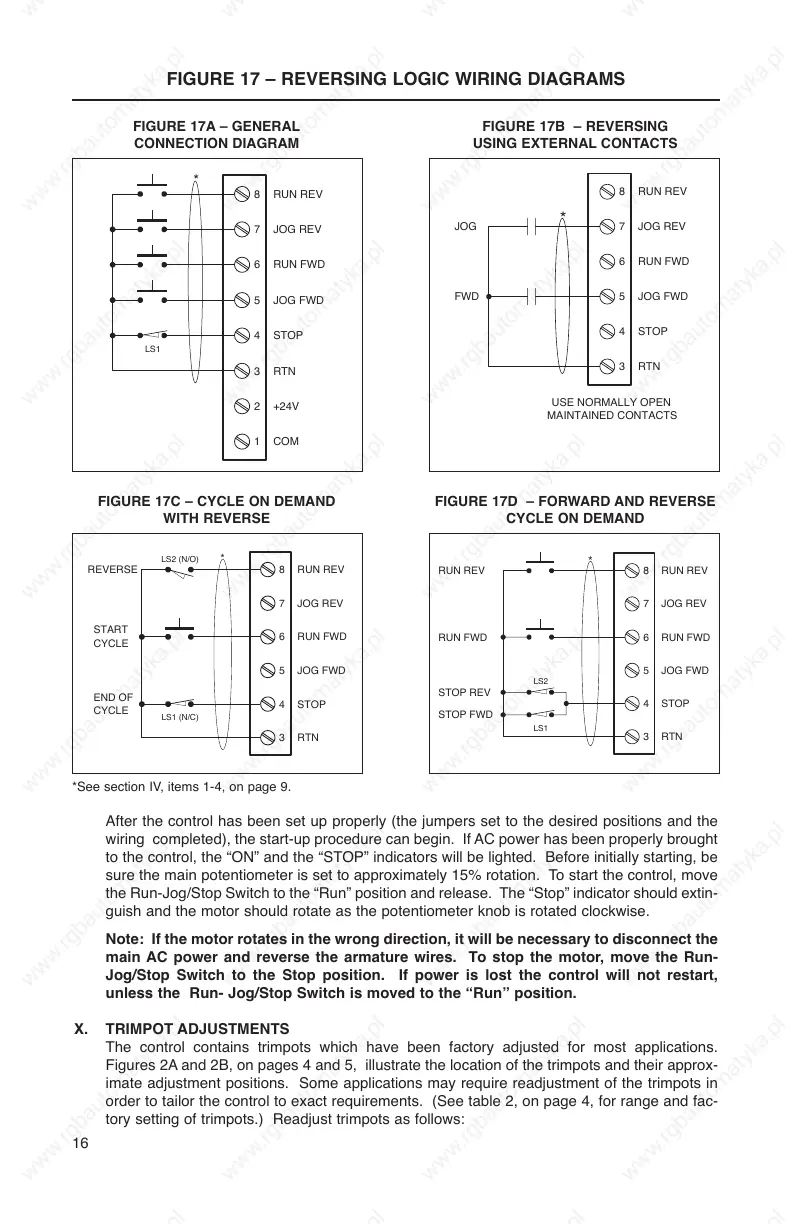

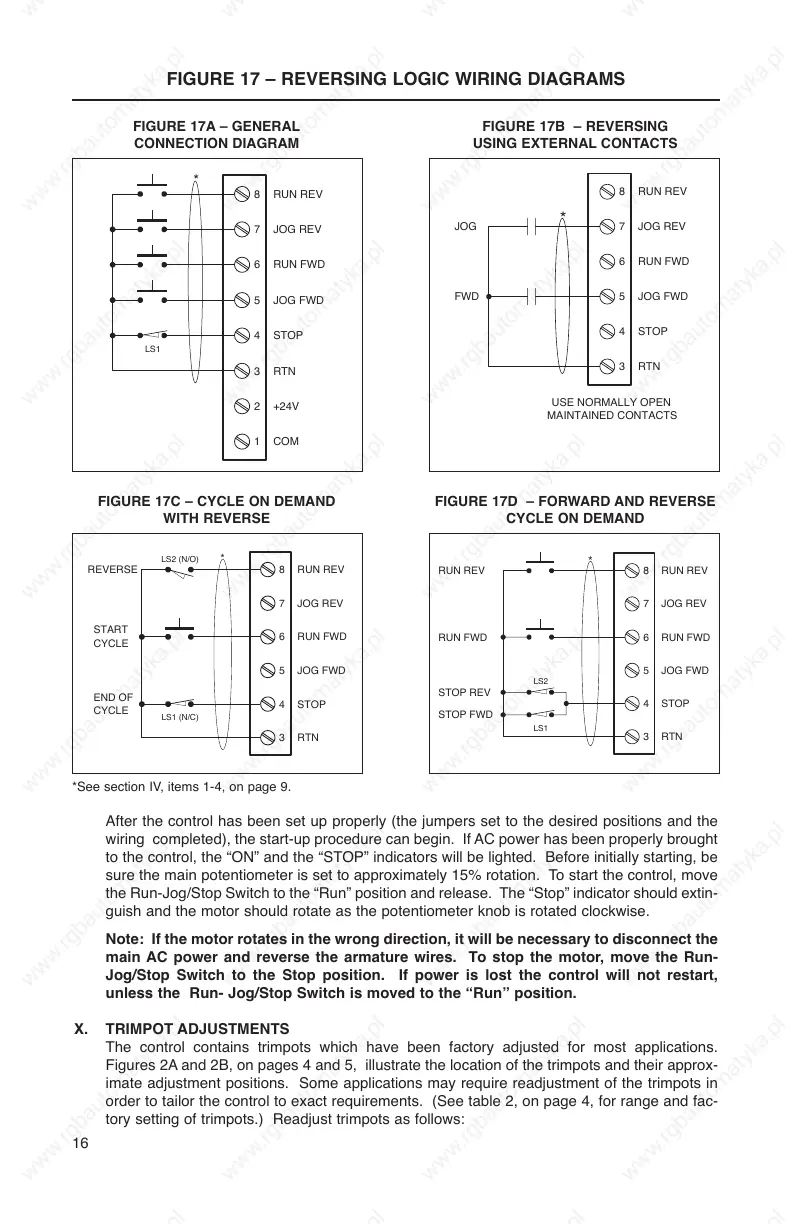

FIGURE 17A – GENERAL

CONNECTION DIAGRAM

FIGURE 17 – REVERSING LOGIC WIRING DIAGRAMS

FIGURE 17B – REVERSING

USING EXTERNAL CONTACTS

FIGURE 17C – CYCLE ON DEMAND

WITH REVERSE

FIGURE 17D – FORWARD AND REVERSE

CYCLE ON DEMAND

*See section IV, items 1-4, on page 9.

Loading...

Loading...