5

Installation, Operation and Maintenance Manual

D I S T R I B U T E D V A L V E S

Threaded style lug valves are recommended

for end-of-line or equipment isolation service.

The WKM MA High Performance

Butterfly Valve can handle flow from either

direction in end-of-line service.

To prevent unintentional removal of the seat

retainer with pressure on the valve, it is

recommended that the valve be installed with

the seat retainer against the upstream flange

if possible.

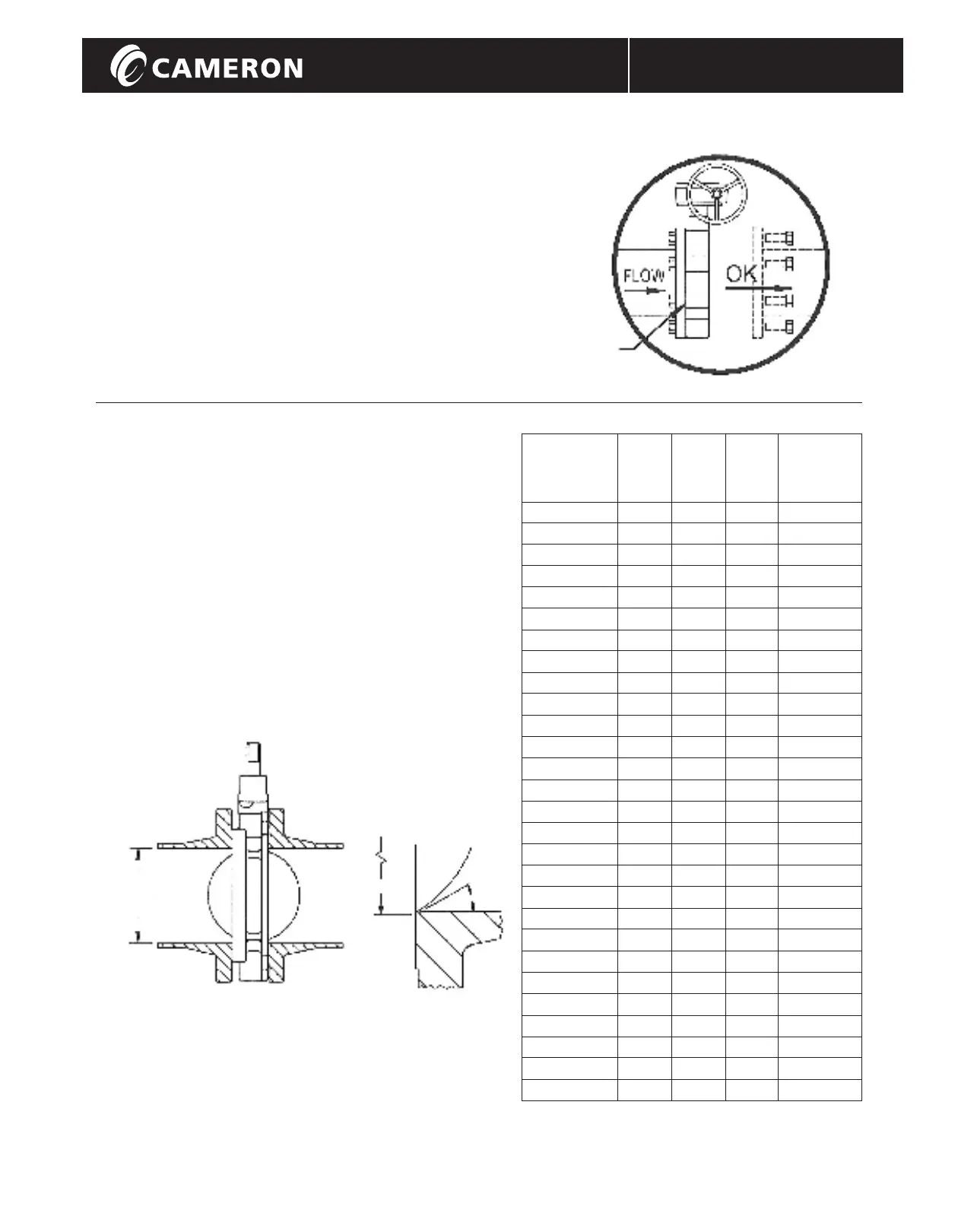

DynaCentric

Disc/Pipe Clearance

Seat Retainer

Valve Size Schd Schd Schd Diameter

and Class 40 XS 120 (in.)

(extra

strong)

3" - 150 X X X 2.75

3" - 300 X X X 2.75

3" - 600 X X X 2.75

4" - 150 X X 3.85

4" - 300 X X 3.85

4" - 600 X X X 3.65

6" - 150 X X 5.90

6" - 300 X X 5.90

6" - 600 X X X 5.50

8" - 150 X 7.90

8" - 300 X X 7.90

8" - 600 X X X 7.40

10" - 150 X 10.00

10" - 300 X X 9.80

10" - 600 X X X 9.06

12" - 150 X 11.90

12" - 300 X X 11.75

12" - 600 X X X 11.75

14" - 150 X 13.06

14" - 300 X X 13.00

16" - 150 X 15.00

16" - 300 X X 14.68

18" - 150 X 16.87

18" - 300 X X 16.50

20" - 150 X 18.81

24" - 150 X 22.62

24" - 300 X X 22.06

30" - 150 X X X 28.02

Table 1 - Disc Clearance

Before beginning installation, note the following:

Disc/pipe clearance should be checked before

beginning installation to avoid the possibility of

scraping on the disc edge on the pipe I.D. and

damaging the sealing surface.

Minimum pipe I.D. required for disc swing clearance:

Class 150 valves - Schedule 40 pipe or equivalent

Class 300 valves - Schedule XS pipe or equivalent

Class 600 valves - Schedule 120 pipe or equivalent

Consult Table 1 for required flange modifications for

other pipe schedules.

Figure 7 - Disc / Pipe Clearance

ØD

30°

Minimum Disc/Pipe

Swing Clearance

X

WKM-MA-HPBV-IOM

End-of-Line Service

Loading...

Loading...