3

TF2101,TF2111,TQ3010,TQ3011,TX2101,TX2118

Installation(Continued)

Donotlocatethe

compressorair

inletnearsteam,paintspray,

sandblastareasoranyothersource

ofcontamination.

NOTE:Ifcompressoroperatesinahot,

moistenvironment,supplycompressor

pumpwithclean,dryoutsideair.Supply

airshouldbepipedinfromexternal

sources.Fortwo-stagecompressors

only,useadapterkit(TF060502AV)

toconnectpipingtocompressor.Two

adapterkitsareneededfortwo-stage

10and15HPunits.

TANKMOUNTING

Thetankshouldbeboltedintoaflat,

even,concretefloororonaseparate

concretefoundation.Vibrationisolators

shouldbeusedbetweenthetankleg

andthefloor.ModelMP367700AJ

isolatorpadsarerecommendedfor

horizontalunits.ModelMP345700AJ

isolatorpadsarerecommendedfor

verticalunits.Whenusingisolator

pads,donotdrawboltstight.Allow

thepadstoabsorbvibrations.When

isolatorsareused,aflexiblehoseor

couplingshouldbeinstalledbetween

thetankandservicepiping.

Failure

toproperlyinstallthe

tankcanleadtocracks

attheweldedjointsand

possiblebursting.

PIPING

Neveruseplastic

(PVC)pipefor

compressedair.Seriousinjuryor

deathcouldresult.

Anytube,pipeorhoseconnectedto

theunitmustbeabletowithstandthe

temperaturegeneratedandretainthe

pressure.Allpressurizedcomponents

oftheairsystemmusthaveapressure

ratinghigherthanorequaltothe

200psifortwo-stagecompressorsor

150psiforsinglestagecompressors

ASMEsafetyvalvesetting.

Incorrectselectionandinstallationof

anytube,pipeorhosecouldresultin

burstingandinjury.Connectpiping

systemtotankusingthesamesize

fittingasthedischargeport.

INSTALLINGASHUT-OFFVALVE

Ashut-offvalveshouldbeinstalled

onthedischargeportofthetankto

controltheairflowoutofthetank.

Thevalveshouldbelocatedbetween

thetankandthepipingsystem.

Neverinstalla

shut-offvalve

betweenthecompressorpump

andthetank.Personalinjuryand/

orequipmentdamagemayoccur.

Neverusereducersindischarge

piping.

Whencreatingapermanentlyinstalled

systemtodistributecompressedair,

findthetotallengthofthesystemand

selectpipesizefromthechart.Bury

undergroundlinesbelowthefrostline

andavoidpocketswherecondensation

cangatherandfreeze.

Applyairpressuretothepiping

installationandmakesurealljointsare

freefromleaksBEFOREunderground

linesarecovered.Beforeputtingthe

compressorintoservice,findandrepair

allleaksinthepiping,fittingsand

connections.

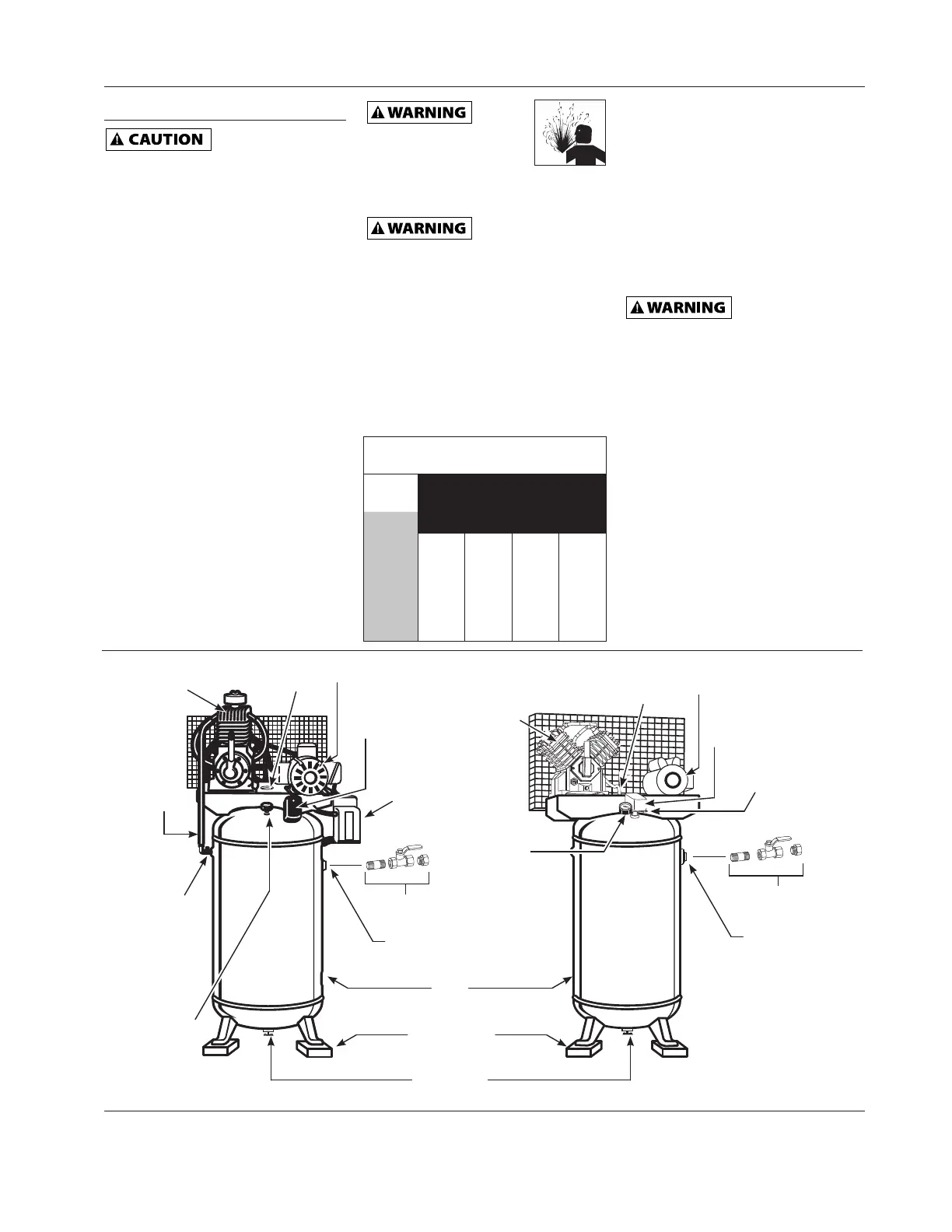

Chart1:MinimumPipeSizefor

CompressedAirLine(ininches)

LengthOfPiping

System(infeet)

CFM 25 50 100 250

10 1/2 1/2 3/4 3/4

20 3/4 3/4 3/4 1

40 3/4 1 1 1

60 3/4 1 1 1

100 1 1 1 1-1/4

DrainValve

IsolationPad

(availableseparately)

Tank

Discharge

Port

TankShut-OffValve

(availableseparately)

Discharge

Port

TankShut-OffValve

(availableseparately)

Pressure

Gauge

Pressure

Gauge

FactoryMounted

MagneticStarter

(notonallunits)

Pressure

Switch

Pressure

Switch

Safety

Valve

Motor

Motor

Pump

Pump

Check

Valve

Discharge

Tube

Discharge

Tube

SafetyValve

Access

Figure1-VerticalUnitIdentification

Loading...

Loading...