Installation(Continued)

WIRING

Allwiring

andelectrical

connectionsmustbeperformedby

aqualifiedelectrician.Installations

mustbeinaccordancewithlocal

andnationalcodes.

Overheating,short

circuitingandfire

damagewillresultfrominadequate

wiring.

Wiringmustbeinstalledinaccordance

withNationalElectricalCodeandlocal

codesandstandardsthathavebeenset

upcoveringelectricalapparatusand

wiring.Theseshouldbeconsultedand

localordinancesobserved.Becertain

thatadequatewiresizesareused,and

that:

1. Serviceisofadequateampere

rating.

2. Thesupplylinehasthesame

electricalcharacteristics(voltage,

cyclesandphase)asthemotor.

3. Thelinewireisthepropersize

andthatnootherequipmentis

operatedfromthesameline.The

chartgivesminimumrecommended

wiresizesforcompressor

installations.

Recommendedwiresizesmaybelarger

thantheminimumsetupbylocal

ordinances.Ifso,thelargersizewire

shouldbeusedtopreventexcessive

linevoltagedrop.Theadditionalwire

costisverysmallcomparedwiththe

costofrepairingorreplacingamotor

electrically“starved”bytheuseof

supplywireswhicharetoosmall.

GROUNDING

Improperlygrounded

electricalcomponents

areshockhazards.

Makesureallthecomponents

areproperlygroundedtoprevent

deathorseriousinjury.

Thisproductmustbegrounded.

Groundingreducestheriskofelectrical

shockbyprovidinganescapewire

fortheelectriccurrentifshortcircuit

occurs.Thisproductmustbeinstalled

andoperatedwithapowercordor

cablethathasagroundingwire.

MOTORHOOKUPANDSTARTER

INSTALLATION

Branchcircuitprotectionmustbe

providedasspecifiedintheUnited

StatesNationalElectricalCode,Chapter

2,“WiringDesignandProtection.”

Article210,usingtheapplicablearticle

“ForMotorsandMotorControllers,”

(Article430,Table430-152).

IMPORTANT:Overloadprotection

isrequiredforallmotors.Certain

motorshavethisprotectionbuilt-in.

Todetermineifamotorhasbuilt-in

overloadprotection,refertotheframe

sizeonthemotornameplate.

MotorswithframesizeR56HZ,Y56Y

orL143Tincludebuilt-inoverload

protection.Noadditionalprotectionis

required.UseFigure3wiringdiagram.

Motorswithframesizes184T,215T,

254Tor284Tdonothavebuilt-in

overloadprotection.Amagnetic

starterisrequired.UseFigure4wiring

diagram.

Tochangetothealternatevoltage

onthreephasemotorswith230/460

ratings:

1. Rewiremotorperdataplateon

motororinstructionsheet.

2. Checkelectricratingofmagnetic

starterandreplacethermal

overloadelementsormagnetic

starterasrequired.Thevoltageand

amperageratingsarelistedonthe

motornameplate.

DIRECTIONOFROTATION

NOTE:Improperrotationwillresultin

reducedunitlife.

Thedirectionofrotationmustbe

counterclockwise(asshownbythe

arrowontheflywheel)whilefacing

theflywheelsideofthepump.The

motornameplatewillshowwiring

informationforcounterclockwise

rotation.

Theproperdirectionisvery

important.Thedirectionofrotation

of3phasemotorscanbereversed

byinterchanginganytwomotor-line

leads.Forsinglephasemotors,referto

themotornameplate.

OperatingInstructions

4

Chart2:MinimumWireSize

Use75°CCopperWire

Single

Phase

Three

Phase

HP

Amps

230V

208/

230V

460/

575V

SPL

Upto22.0

10

AWG

5.0

8

AWG

12

AWG

14

AWG

7.5

8

AWG

10

AWG

12

AWG

10.0

8

AWG

12

AWG

15.0

6

AWG

10

AWG

25.0

3

AWG

8

AWG

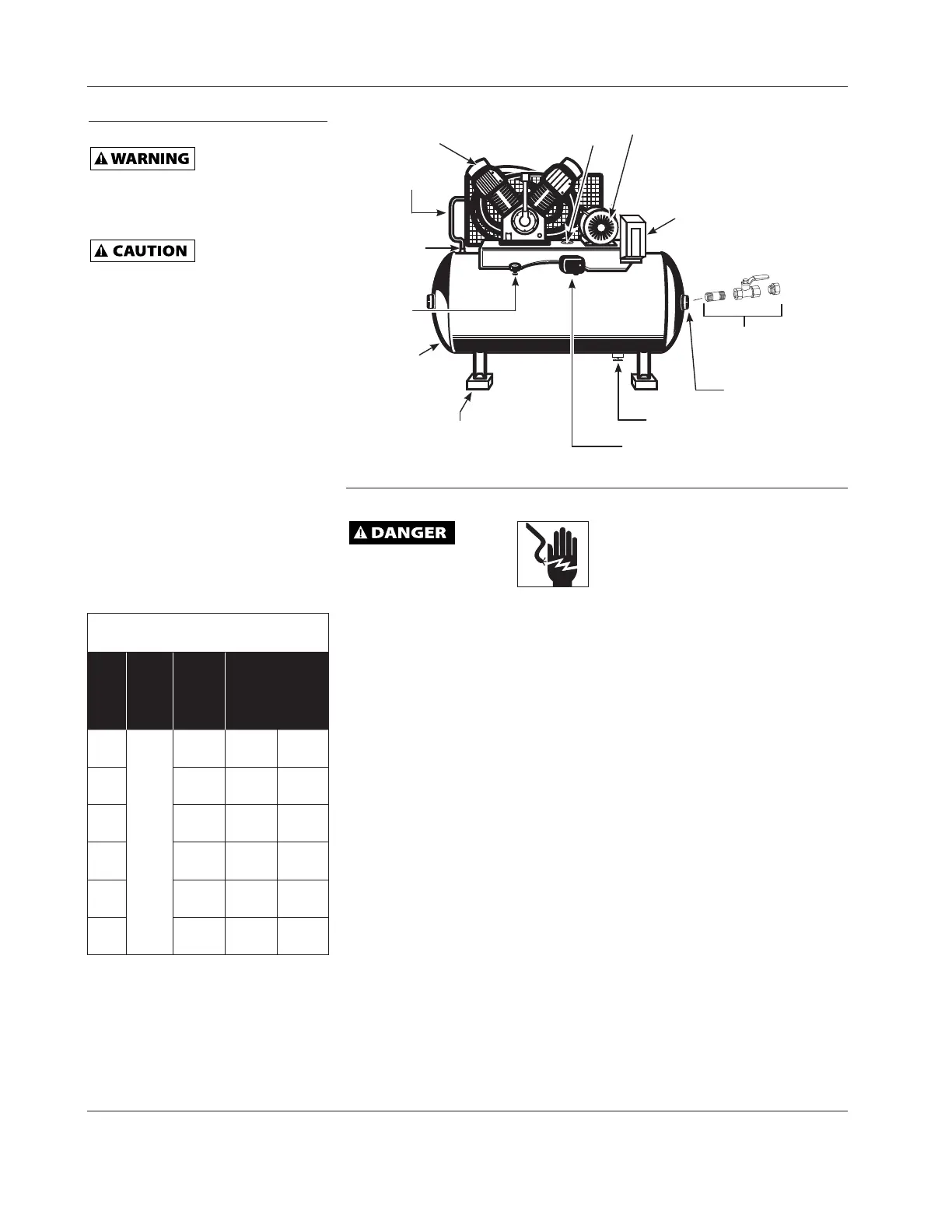

IsolationPad

(availableseparately)

Tank

TankShut-OffValve

(availableseparately)

FactoryMounted

MagneticStarter

(notonallunits)

Pump

Discharge

Tube

Motor

SafetyValve

Access

Figure2-HorizontalUnitIdentification

DrainValve

DischargePort

PressureSwitch

Pressure

Gauge

Check

Valve

Loading...

Loading...