Operation

IMPORTANT:Checkmotorrotation

beforeoperatingthecompressor.

Alllubricatedcompressorpumps

dischargesomecondensedwater

andoilwiththecompressedair.

Installappropriatewater/oilremoval

equipmentandcontrolsasnecessaryfor

theintendedapplication.

Failuretoinstall

appropriatewater/

oilremovalequipmentmayresultin

damagetomachineryorworkpiece.

GUARDING

The

belt

guardprovidedmust

beinstalledbefore

operatingtheunit.

Allmovingpartsmustbeguarded.

Allelectricalcoversmustbeinstalled

beforeturningonthepower.

LUBRICATION

THISUNIT

CONTAINSNOOIL.

Beforeoperatingcompressor,fill

crankcasewithcompressoroil

accordingtotheoilcapacitychart.

Someresidualoilmaystillbeinthe

pumpleavingathincoatonthesight

glass,however;thereisnotenough

oiltooperatetheunit.Fillpumpwith

single-viscosity,ISO100,non-detergent,

compressoroil.

UsepartnumberST126700AV,

compressoroilorMobil1

®

5W30or

10W30syntheticoilmayalsobeused.

Addoilonlythroughtheoilfillplug.

Pouringoilintoanyotherorificewill

causeoiltoleakandsprayoutduring

operation.

TF2101,TF2111,TQ3010,TQ3011,TX2101,TX2118

5

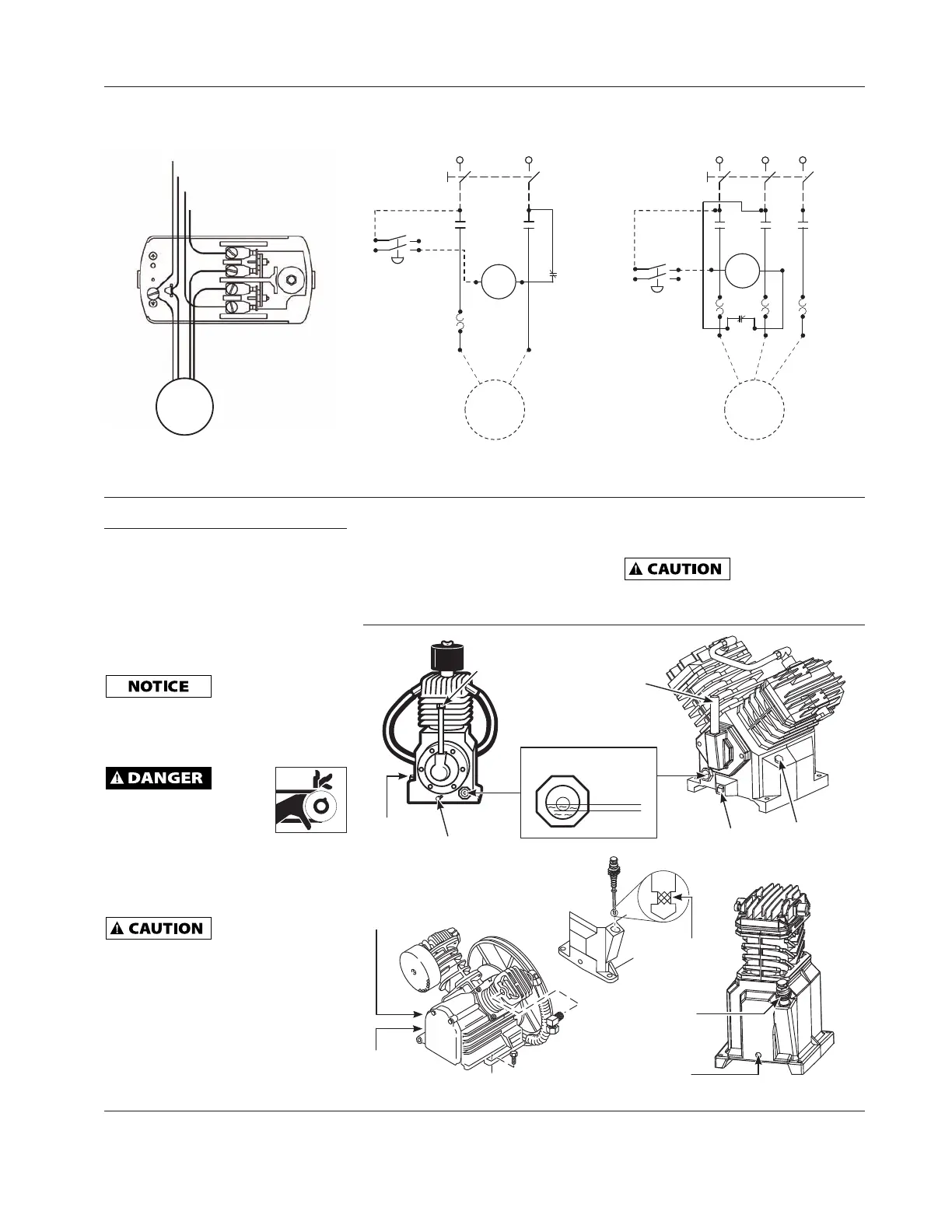

L1

L2

T2T1

X2

T2

X2

L1

L2

L3

T3

T1

Filltothecenterofthesightgaugeor

maximummarkondipstick(see

Figure5).

Usinganyother

typeofoilmay

shortenpumplifeanddamage

valves.

Low

Max

Figure3-ForMotorFrameSizes

R56HZ,Y56YorL143T.

RefertoMotorNameplate

Motor

Ground

L3(for3phasewiringonly)

L2

L1

SinglePhase/ThreePhase

WiringDiagram

Figure4-ForMotorFrameSizes184T,215T,254Tor284T.

RefertoMotorNameplate

SinglePhase

WiringDiagram

Motor

Circuit

Breaker

orFused

Disconnect

ThreePhase

WiringDiagram

Motor

Coil

Coil

Circuit

Breaker

orFused

Disconnect

Over

Load

Over

Load

Thermal

Unit

Thermal

Units(3)

Figure5-OilFillDiagrams

Full

Low

SightGauge

OilFill

Plug

Breather

Cap

Breather

Cap

OilFill

Plug

Oil

Drain

Plug

Fill

Line

OilDrain

Plug

Drainon

side

Dipstickand

OilFill

Drain

Dipstickand

OilFill

Pressure

Switch

Pressure

Switch

Loading...

Loading...