TF2101,TF2111,TQ3010,TQ3011,TX2101,TX2118

7

Maintenance(Continued)

AIRFILTER

Neverrunthecompressorpump

withoutanintakeairfilternor

withacloggedintakeairfilter.Use

compressedairtoblowthefilterclean.

Donotwashoroiltheelement.Ifit

cannotbeblownclean,thefiltermust

bereplaced.Operatingcompressor

withadirtyfiltercancausehigh

oilconsumptionandincreaseoil

contaminationinthedischargeair.

INTERCOOLER(TWO-STAGE

COMPRESSORSONLY)

Intercoolerfins

aresharp,always

wearglovesandusecarewhenyou

cleanorworkneartheintercooler.

Weekly,checktheintercoolertobesure

allfittingsaresecureandtight.Blowall

dirt,dustandotheraccumulationsfrom

theintercoolerfins.

COMPONENTS

Turnoffallpoweranduselightair

pressuretoblowdustandforeign

materialfromcylinderhead,motor,fan

blades,airlines,intercoolerandtank

onamonthlybasis.

BELTS

Lockoutandtag

thepowerthen

releaseallpressurefromthetankto

preventunexpectedmovementofthe

unit.

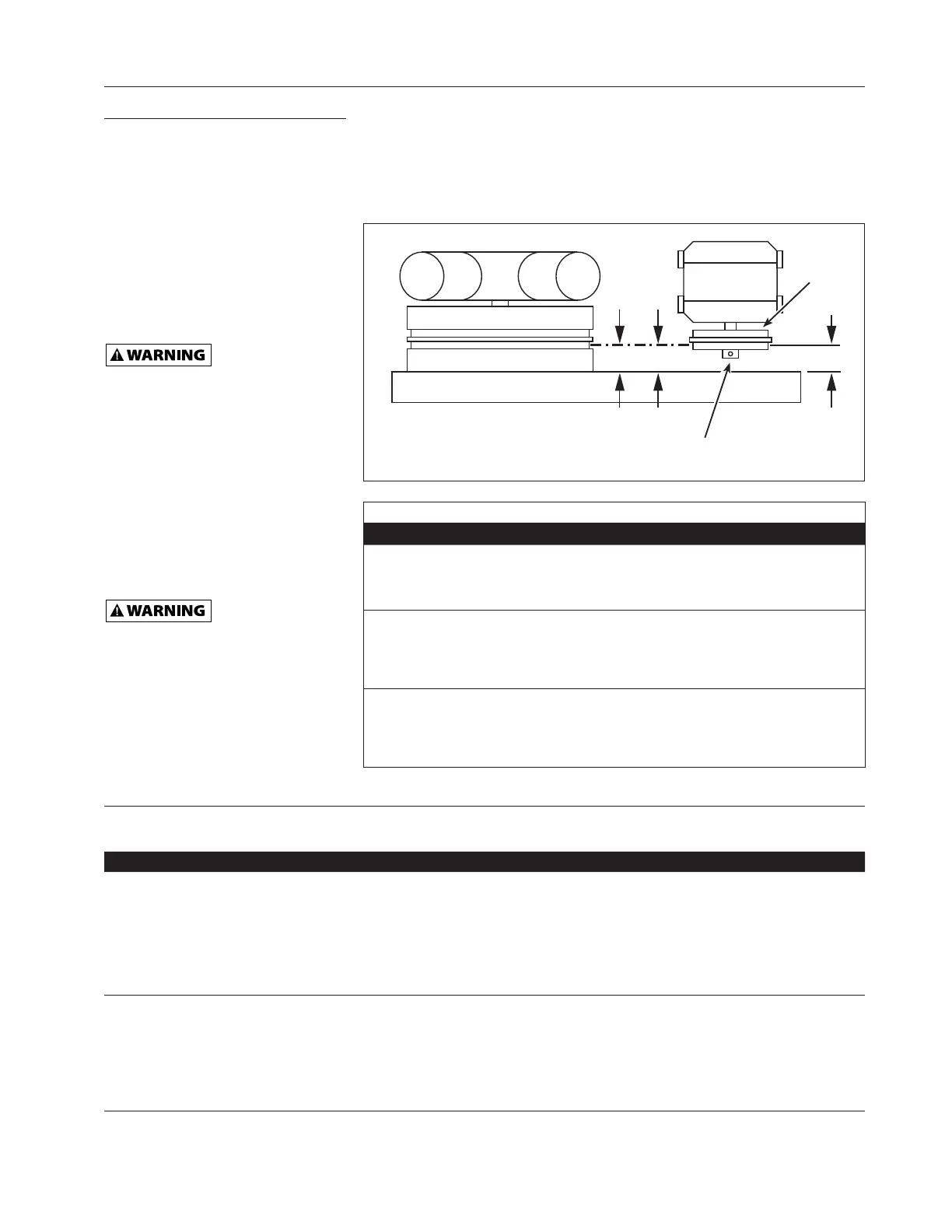

Checkbelttensionevery3months.

Adjustbelttensiontoallow3/8to1/2

inchdeflectionwithnormalthumb

pressure.Also,alignbeltsusinga

straightedgeagainstthefaceofthe

flywheelandtouchingtherimonboth

sidesoftheface.Thebeltsshouldbe

paralleltothisstraightedge(see

Figure9).DimensionAshouldbethe

sameasBandCtoensureproper

alignmentofthebelts.

Slotsinthebed-plateallowforsliding

themotorbackandforthtoadjustbelt

tension.

STORAGE

Ifcompressoristobestoredforashort

periodoftime,makesurethatitis

storedinanormalpositionandina

coolprotectedarea.

� B

C

AirCompressor

Motor

Flywheel

StraightEdge

Setscrew

Motor

Drive

Pulley

Figure9-TopView

TroubleshootingChart

Symptom PossibleCause(s) CorrectiveAction

Motorhumsand

runsslowlyornot

atall

1.Lowvoltageornovoltage 1.Checkwithvoltmeter,checkoverloadrelayinmagneticstarterorreset

switchonmotor.Ifoverloadorresetswitchtripsrepeatedly,findand

correctthecause.Seenextitem

2.Shortedoropenmotorwinding 2.Replacemotor

3.Malfunctioningcheckvalveor

unloadervalve

3.Replacecheckvalveorunloadervalve

4.Malfunctioningpressureswitch-

contactswillnotclose

4.Repairorreplacepressureswitch

Resetmechanism

cutsoutrepeatedly

orfusesblow

repeatedly

1.Pressureswitchsettoohigh 1.Adjustorreplace

2.Malfunctioningcheckvalve 2.Cleanorreplacefaultyvalve

3.Incorrectfusesizeormagnetic

starterheaters

3.Besurethatfusesandheatersareratedproperly

4.Malfunctioningmotor 4.Replacemotor

5.LooseWiring 5.Checkallelectricalconnections

MAINTENANCESCHEDULE

Operation Daily Weekly Monthly 3Months

CheckSafetyValve

�

DrainTank(SeeFigure6)

�

CheckOilLevel

�

CleanorChangeAirFilter

�

CheckIntercooler(two-stage

compressorsonly)

�

CleanUnitComponents

�

CheckBeltTightness

�

ChangeOil(SeeFigure5)

�

ChangeOilFilter(Pressure

lubricatedpumpsonly)

�

Loading...

Loading...