16

MAINTENANCE

LUBRICATION

The maintenance chart on page 12 contains

lubrication maintenance to be performed on

the System. Refer to the following

recommendations for optimal lubrication.

NOTE: Use lubricants designed for extreme and/or

wet environments.

NOTE: Remove Skin to access lubrication points

shown below.

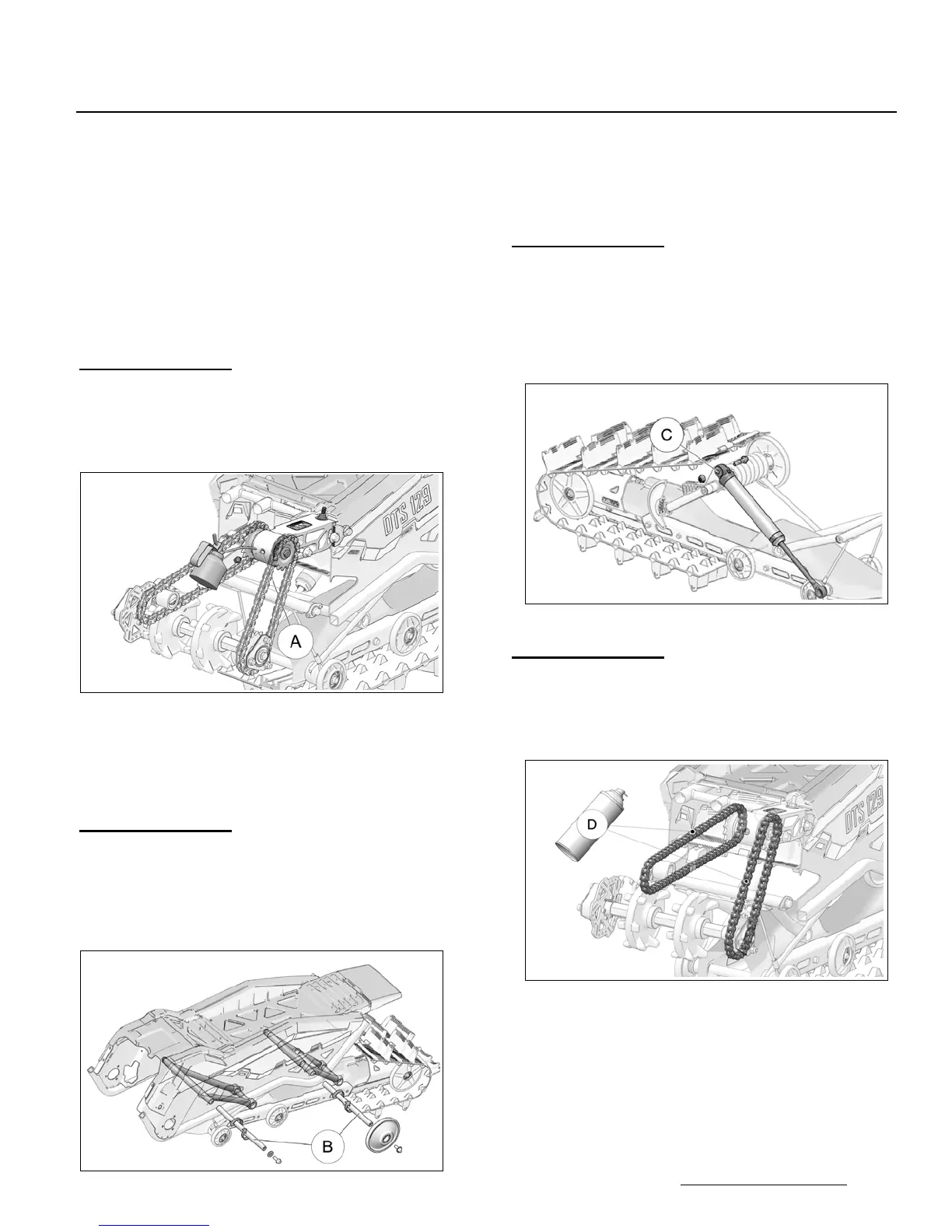

REFERENCE “A”

CHAIN TENSIONER

Pour 6-8 cc of oil through hole (A) located at front

end of chain tensioner.

NOTE: Use a SAE 80W-90 grade oil designed for high

pressure applications.

CAUTION: Do not exceed the recommended

quantity of oil.

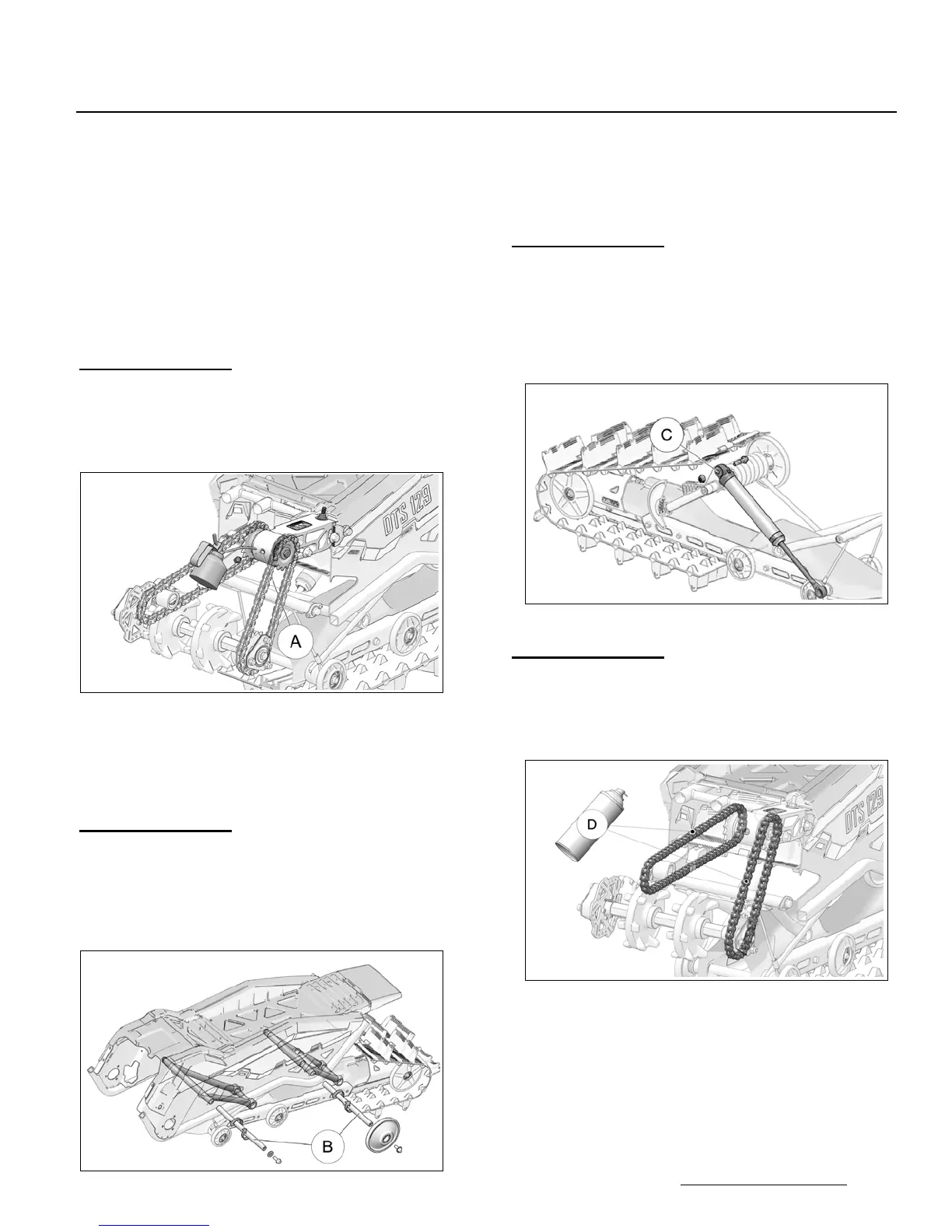

REFERENCE “B”

SUSPENSION ARMS

Apply 3-4 cc of grease evenly all around and

along the entire length of the suspension arm

pivot shafts (B).

NOTE: Tension in the Suspension torsion spring must

be released before attempting to remove the

side panels to grease the suspension arm

shafts.

REFERENCE “C”

SHOCK ABSORBER UPPER MOUNT

Remove bolt and nut securing upper mount point

(C) of shock absorber to suspension arm and

apply grease to exterior diameter of shock

absorber’s upper mounting point bushing.

REFERENCE “D”

CHAINS

Apply aerosol grease on the Conversion system’s

primary and secondary drive chains (D).

Loading...

Loading...