8

ADJUSTMENTS

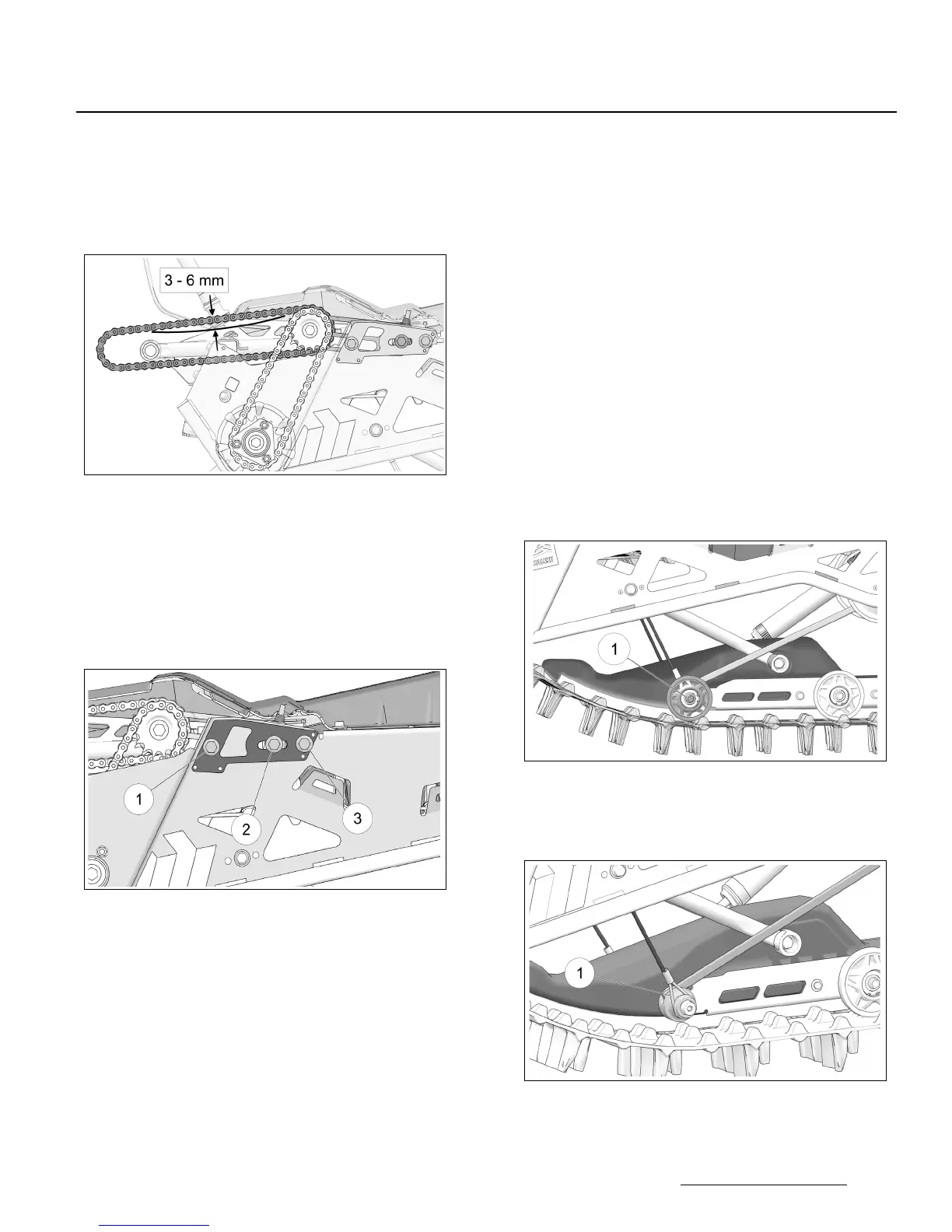

• Once the secondary drive chain tension is set,

finalize tension adjustment of primary drive

chain. Apply pressure at center of the two drive

sprockets. The chain should have 3-6 mm (1/8

-1/4 in.) of play. Re-adjust until the right

amount of play is obtained. See Figure 11.

Figure 11

CAUTION: After having adjusted the primary drive

chain and before tightening the mounting bolts,

double-check the secondary drive chain tension.

Re-adjust tension if chain deflection does not

meet requirement.

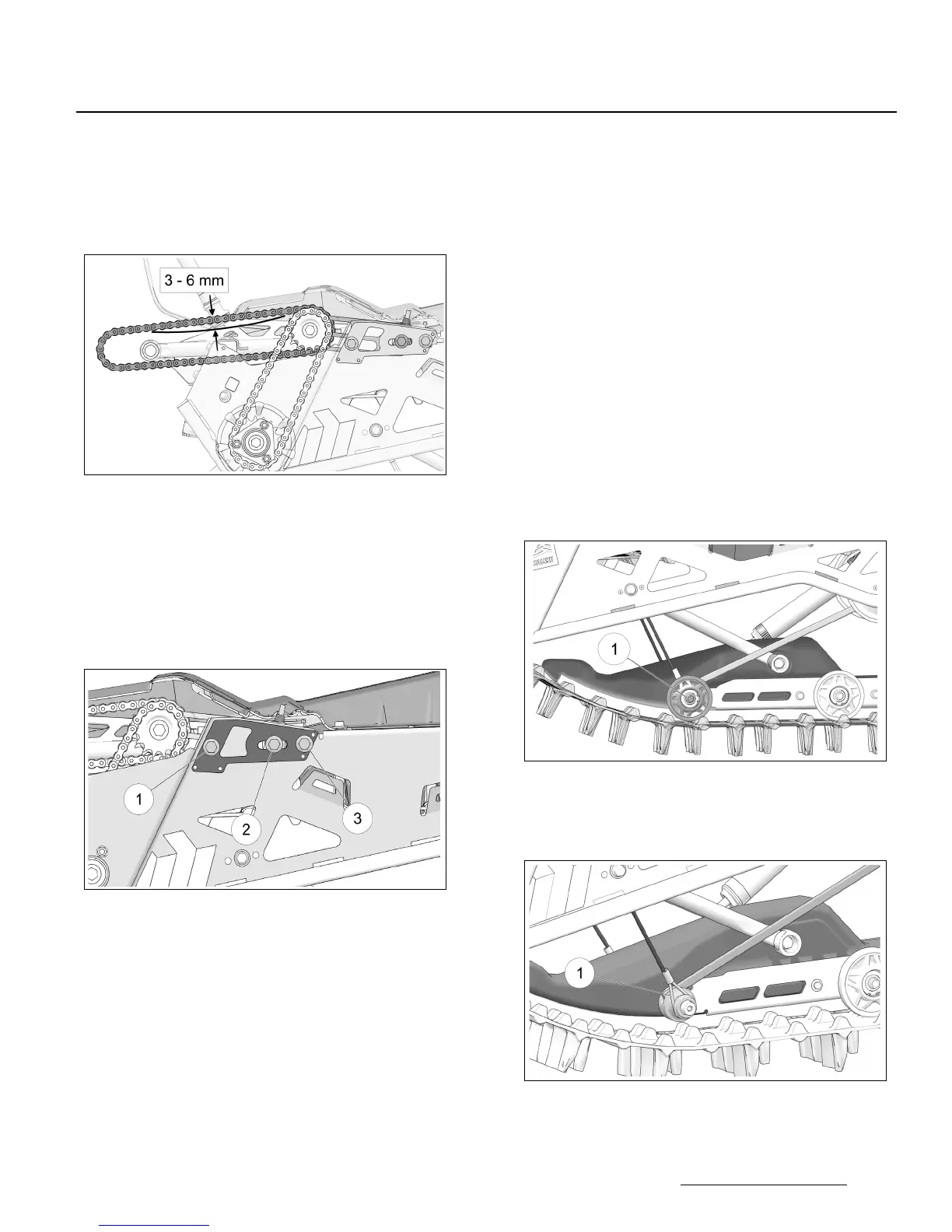

• Re-tighten chain tensioner mounting bolts (1),

(2) and (3) to 90 N-m [67 lb-ft] of torque.

See

Figure 12.

Figure 12

• Drive chain tension set too high can cause

premature wear on drive sprockets and on the

chains themselves. Chains are less likely to

come off and are also less likely to skip on the

sprockets.

CAUTION: A chain tension that is set too high will

result in a loss of power and excessive

mechanical stress put on drive system

components. A chain tension set too high is not

recommended.

• A lower tension in the drive chains increases

the risk of chains coming off or skipping on the

drive sprockets.

NOTE: Once the chain tension adjustments are done,

double-check to make sure that the tension

settings are according to specification.

SUSPENSION ADJUSTMENT

The suspension can be adjusted to fit the rider’s

weight, personal preferences or type of use made

of the vehicle.

NOTE: Camso recommends that the suspension

spring adjustment be made in a workshop/

garage before using the motorcycle.

• Loosen the wheel assembly bolt (1) located

next to the grooved bushing where the long

end of suspension spring sits and remove the

wheel. See

Figure 13.

Figure 13

• Depress suspension to allow removal of limiter

cable loop (1) from groove in spring support

bushing. See

Figure 14.

Figure 14

Loading...

Loading...