Trailer Jockey Operators Handbook

103

4-6 L

UBRICATION

The following paragraphs provide recommendations for lubri-

cating your Trailer Jockey.

All recommendations and lubrication intervals are based on

average operating conditions. Lubricants showing signs of

excessive heat oxidation, dirt, or contamination should be

changed more frequently to prevent these conditions from

occurring. Lubrication and fluid change intervals must be

established on the basis of your individual job conditions.

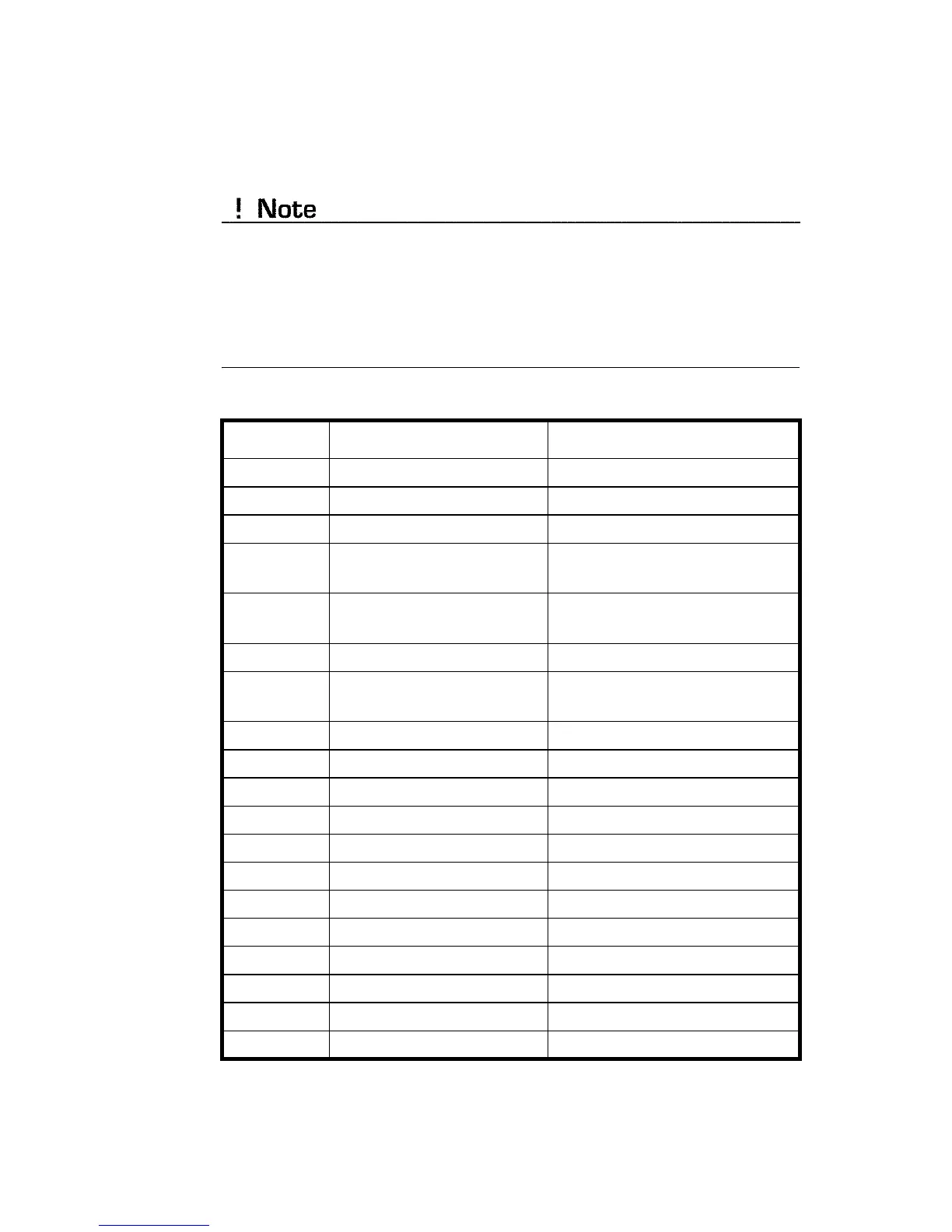

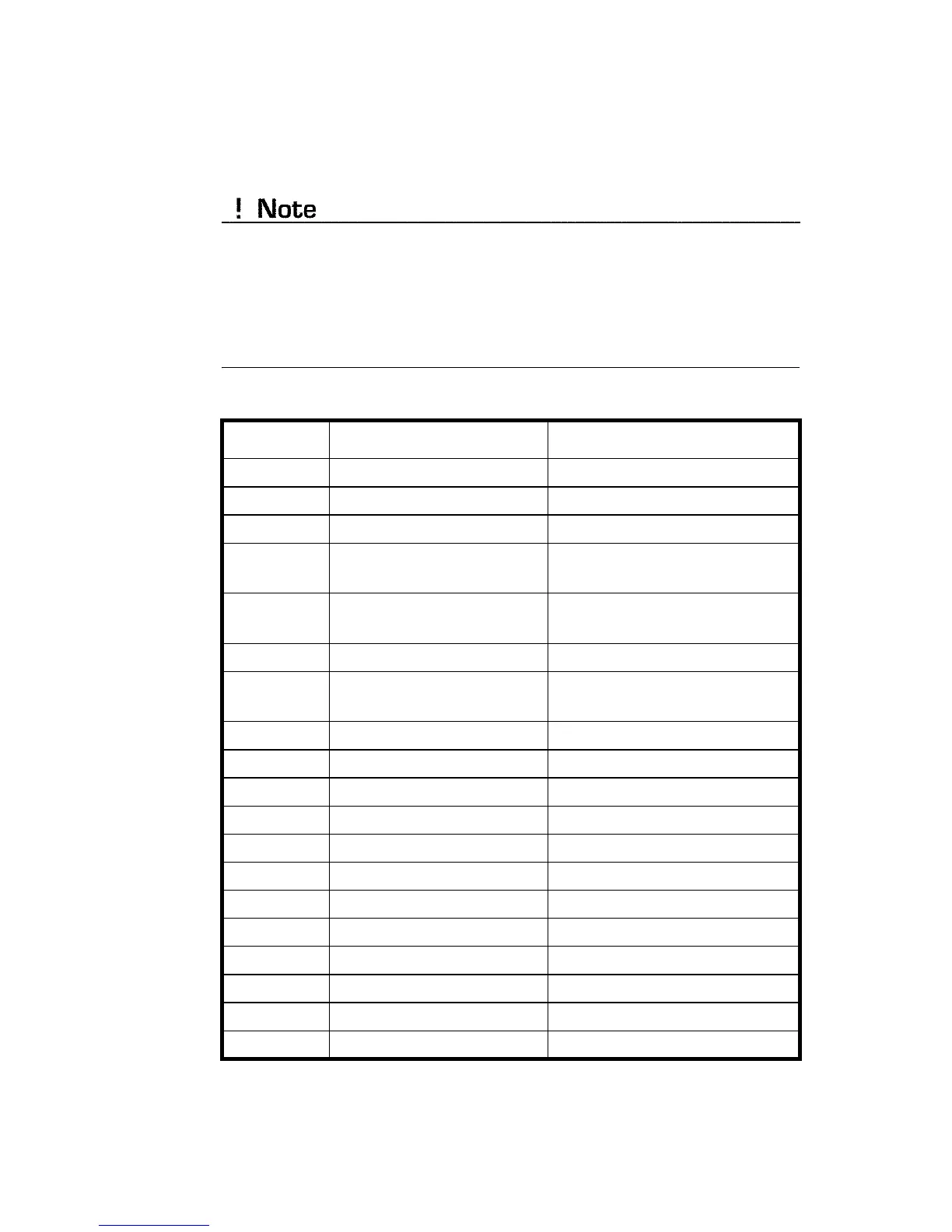

Table 4-6 Lubrication Recommendations

Frequency Item Lubricant/Fluid

Daily Fifth Wheel Surface NLGI-00 Grease

Oscillation Shaft (2 pl) NLGI-00 Grease

Boom Pivot Shaft (2 pl) NLGI-00 Grease

Slack Adjusters (2 front, 2

rear)

NLGI-00 Grease

Monthly or

200 Hrs

Rear Axle Synthetic Gear Lube

Dura Ride Pivot Shaft NLGI-00 Grease

Brake Camshaft (2 front, 2

rear)

NLGI-00 Grease

Lift Cylinder NLGI-00 Grease

Prop Shaft Multipurpose Grease

Auto Lube NLGI-00 Grease

Transmission NLGI-00 Grease

Hydraulic Reservoir NLGI-00 Grease

Steering Knuckles NLGI-00 Grease

Engine Oil NLGI-00 Grease

Spring Pins NLGI-00 Grease

Power Steering Pump NLGI-00 Grease

Tie Rod Ends NLGI-00 Grease

Wheel Bearings NLGI-00 Grease

Cab Tilt Pump NLGI-00 Grease

Loading...

Loading...