20

ENG

“EVD evolution” +030222041 - rel. 1.0 - 01.06.2008

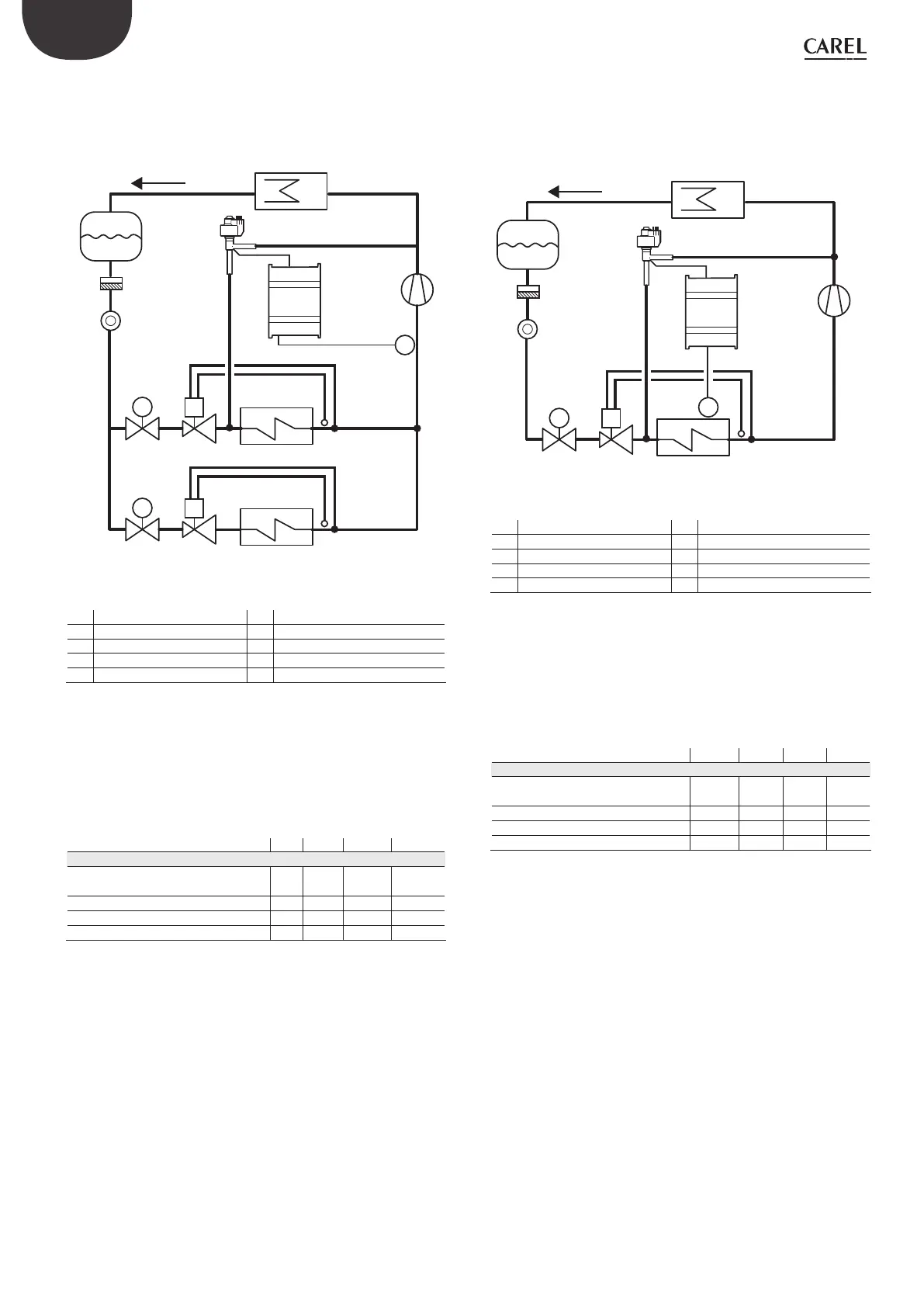

Hot gas bypass by pressure

This control function can be used to control cooling capacity. If there

is no request from circuit B, the compressor suction pressure decreases

and the bypass valve opens to let a greater quantity of hot gas flow and

decrease the capacity of the circuit.

E

V1 V2

M T

E

V1 V2

M

A

B

T

S

F

L

CP

EV

C

S1

EVD

evolution

P

Fig. 5.c

Key:

CP Compressor V1 Solenoid valve

C Condenser V2 Thermostatic expasnion valve

L Liquid receiver EV Electronic valve

F Dewatering filter E Evaporator

S Liquid indicator

For the wiring, see paragraph 2.7 “General connection diagram”.

This involves PID control without any protectors (LowSH, LOP, MOP,

HiTcond, see the chapter on Protectors), without any valve unblock

procedure and without auxiliary control. Control is performed on the hot

gas bypass pressure sensor value read by input S1, compared to the set

point: “Hot gas bypass pressure set point”.

Control is reverse, as the pressure increases, the valve closes and vice-

versa.

Parameter/description Def. Min. Max. UOM

CONTROL

Hot gas bypass pressure set point 3 -20

(290)

200

(2900)

barg

(psig)

PID: proportional gain 15 0 800 -

PID: integration time 150 0 1000 s

PID: derivative time 5 0 800 s

Tab. 5.f

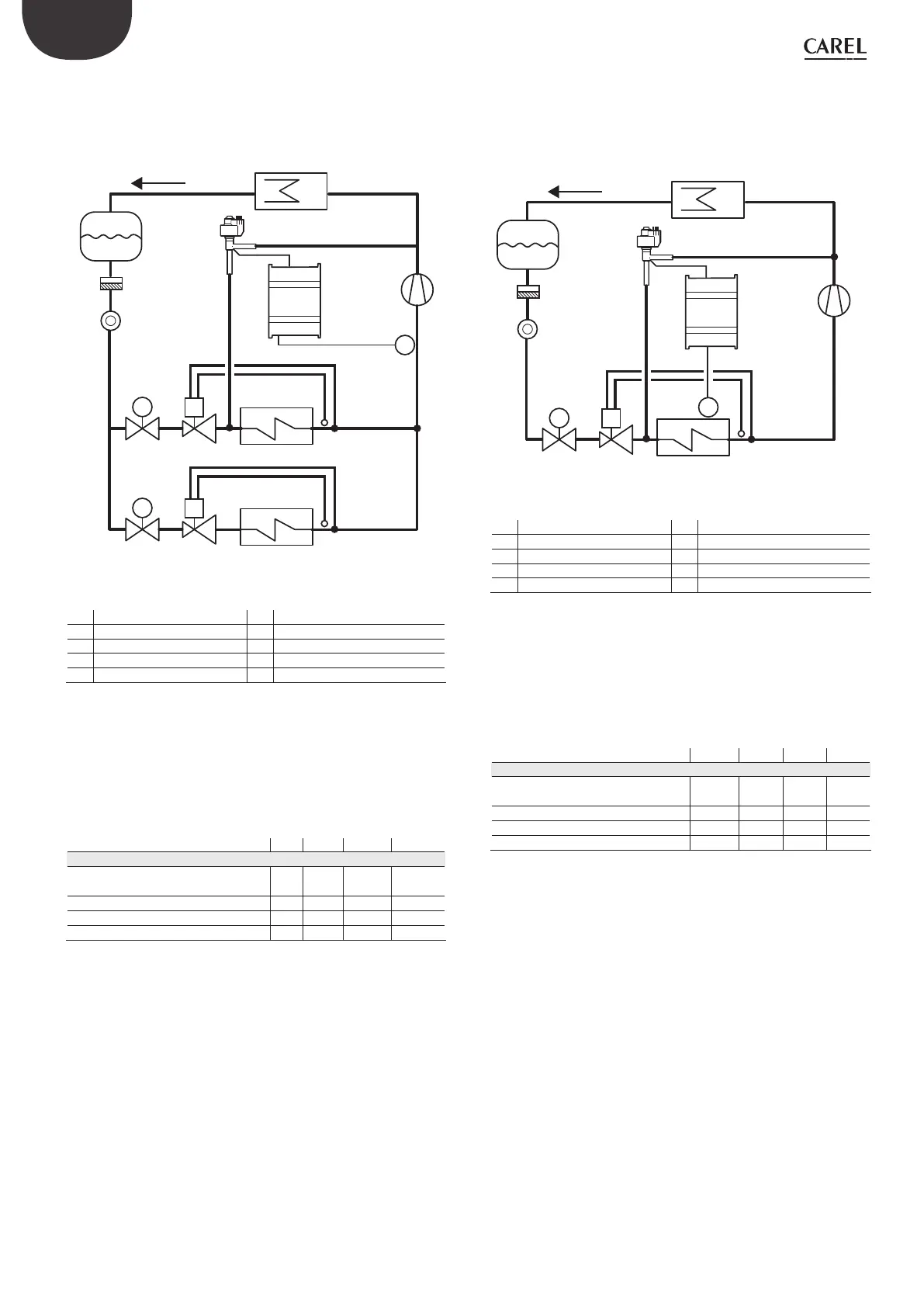

Hot gas bypass by temperature

This control function can be used to control cooling capacity. On a

refrigerated cabinet, if the ambient temperature sensor measures an

increase in the temperature, the cooling capacity must also increase, and

so the valve must close.

E

V1 V2

M T

S

F

L

CP

C

S2

EVD

evolution

T

Fig. 5.d

Key:

CP Compressor V1 Solenoid valve

C Condenser V2 Thermostatic expasnion valve

L Liquid receiver EV Electronic valve

F Dewatering filter E Evaporator

S Liquid indicator

For the wiring, see paragraph 2.7 “General connection diagram”.

This involves PID control without any protectors (LowSH, LOP, MOP,

HiTcond, see the chapter on Protectors), without any valve unblock

procedure and without auxiliary control. Control is performed on the hot

gas bypass temperature sensor value read by input S2, compared to the

set point: “Hot gas bypass temperature set point”.

Control is reverse, as the temperature increases, the valve closes.

Parameter/description Def. Min. Max. UOM

CONTROL

Hot gas bypass temperature set point 10 -60

(-76)

200

(392)

°C (°F)

PID: proportional gain 15 0 800 -

PID: derivative time 150 0 1000 s

PID: integration time 5 0 800 s

Tab. 5.g

Loading...

Loading...