48

1 bar 1,5 bar 2 bar F08-F09

ENGLISH

µC

2

SE - +030220426 - rel. 2.0 - 03.08.2009

- Function of the second pump

H21: This parameter defi nes how the output dedicated to the second pump must be managed.

H21= 0: the second pump is disabled.

H21= 1: the second pump is used only as a backup.

If the fl ow switch and corresponding alarm are activated, the pumps are switched over:

if the alarm passes, a warning is shown on the display and the warning relay is activated, while the •

unit continues to operate with the Backup pump. When the next alarm is activated the pumps will be

switched over.

if the alarm remains active even with the second pump on for longer than the time set for P1, the •

generic alarm is generated and the unit is switched OFF.

H21= 2: the second pump represents a backup pump. The two pumps are never used at the same time

but each 24 hours, are switched over. In the event of fl ow alarms, the logic is the same as for setting 1.

After being switched over due to the fl ow alarm, the 24-hour timer is set to zero.

H21= 3: the second pump is used as an ON/OFF device in the same way as the condenser fan (which in

this case is not present), in ON/OFF mode, with the same settings (in fact in this case the pump replaces

the fan, including the symbol).

H21= 4: the second pump is used for the condenser but is always ON. In this case the pump symbol is

not managed.

Note: In the event of fl ow alarms with automatic reset, 10 attempts are made to restart the pump every

90 seconds, for a maximum time of P02; after the 10 attempts, the alarm becomes manual reset. With the

second pump, the attempt consists in switching over the pump that is on, with the same logic.

- Disable load default values

H22: If this parameter is set to 1, it disables the possibility of restoring the default parameters using the

PRG button at power ON.

- select supervisor protocol

H23: establishes the protocol used for the connection to the supervisor from the serial board RS485

H23 = 0: CAREL protocol (baud rate 19200,…)

H23 = 1: Modbus protocol

• Alarm settings: parameters (P*)

- Flow switch alarm delay when starting pump

P01: Establishes a delay in the recognition of the fl ow switch alarm when starting the pump (this allows

the fl ow-rate to stabilise). In the event of alarms, the compressors are stopped immediately, ignoring the

times.

- Flow switch alarm delay in steady operation

P02: Establishes a delay in the recognition of the fl ow switch alarm in steady operation, so as to fi lter any

variations in fl ow-rate or air bubbles present in the water circuit. In the event of alarms, the compressors

are stopped immediately, ignoring the times.

- Low pressure alarm delay at compressor start

P03: Establishes a delay in the recognition of the low pressure alarm when the compressor starts, so as

to allow stable operating conditions to be reached. This delay is also counted when reversing the 4-way

valve in the refrigerant circuit.

- Part load in high pressure and low pressure in heat pump

P04: enable or disable the part load operation of the circuit in high pressure.

The function is valid if the unit is fi tted with tandem or capacity controlled compressors and pressure

transducers. In the event of high pressure alarms, that is, for values over P18 (hysteresis 0.5 bar), the

controller deactivates a load step in the circuit in question and waits 10 seconds. After this interval, if

the alarm is still active, the unit is stopped, otherwise it continues to operate in part load mode. In this

situation, the display shows the message PH1 and/or PH2, depending on the circuit. This condition

remains active until the pressure falls below the value corresponding to the maximum speed of the

condenser fans (F05+F06). Below this value, the unit reactivates the load step that had previously been

deactivated.

P04=0: capacity control not activated

P04=1: capacity control activated for high pressure

P04=2: capacity control activated for low pressure

P04=3: capacity control activated for high and low pressure

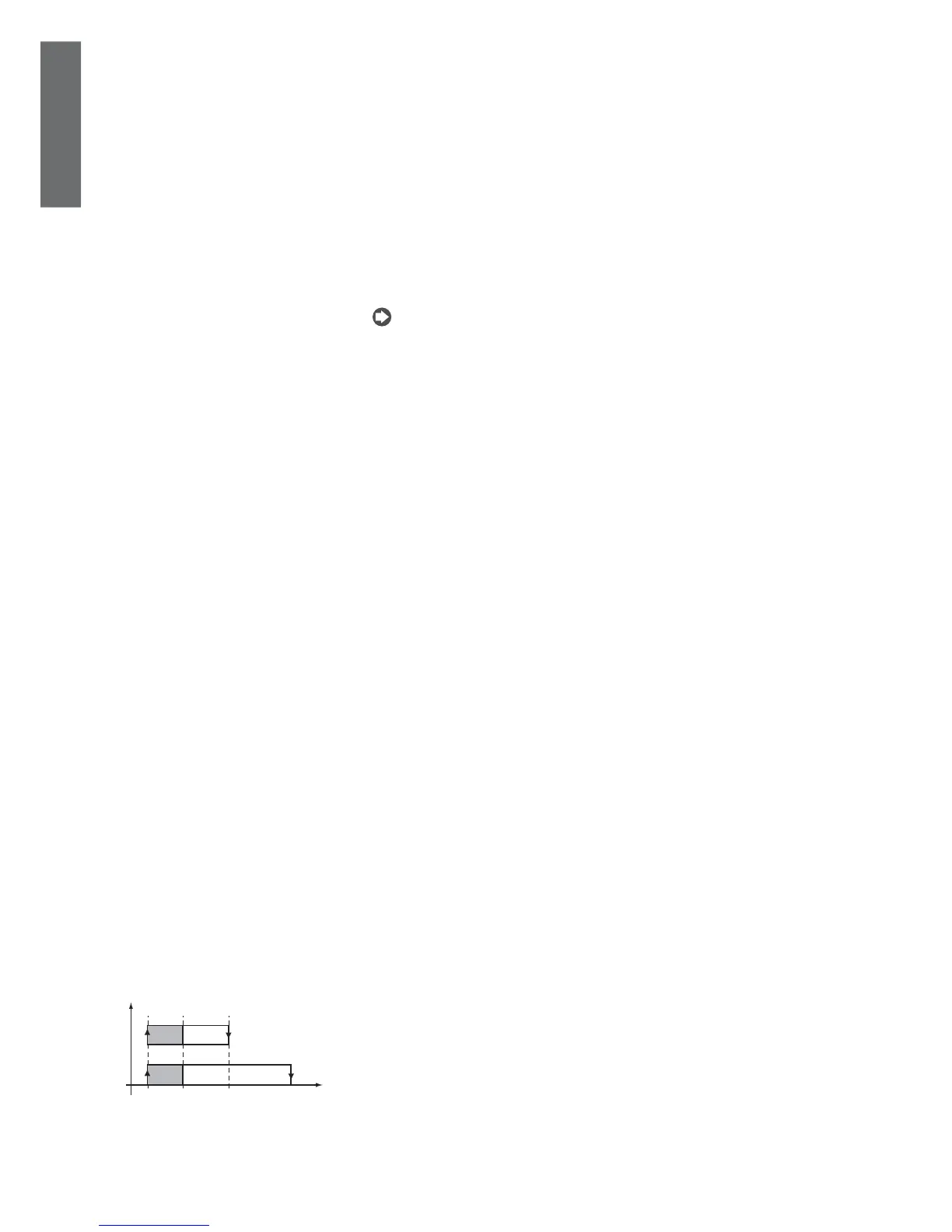

With the unit operating in heat pump mode, due to low outside temperatures or the load the pressure

may fall and stop the unit due to the low pressure alarm. If the circuit has 2 compressor steps and

the pressure remains below the value of one bar for the time P22, the circuit can operate at part load.

This capacity control is not activated when the alarm comes from the digital input. In the event of low

pressure, the controller deactivates one step and if the pressure does not return above the threshold in 10

seconds, the alarm is activated and the circuit is stopped. This function is valid for all units with pressure

transducers.

Fig. 5.b.b

all LP

pressure

Part load in low pressure

parz LP

Loading...

Loading...