V Driver

EV Driver

Expansion

board

EV driver

ENGLISH

µC

2

SE - +030220426 - rel. 2.0 - 03.08.2009

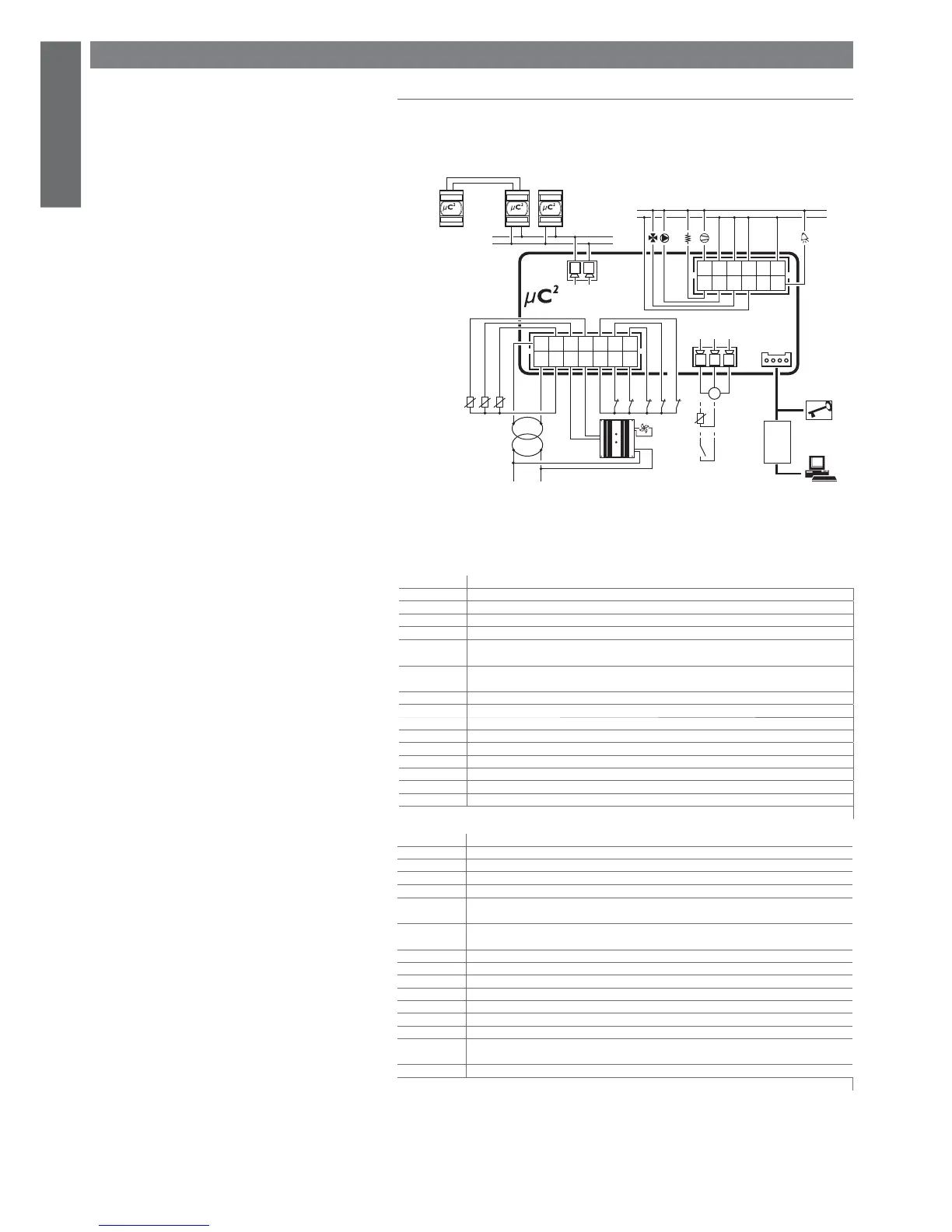

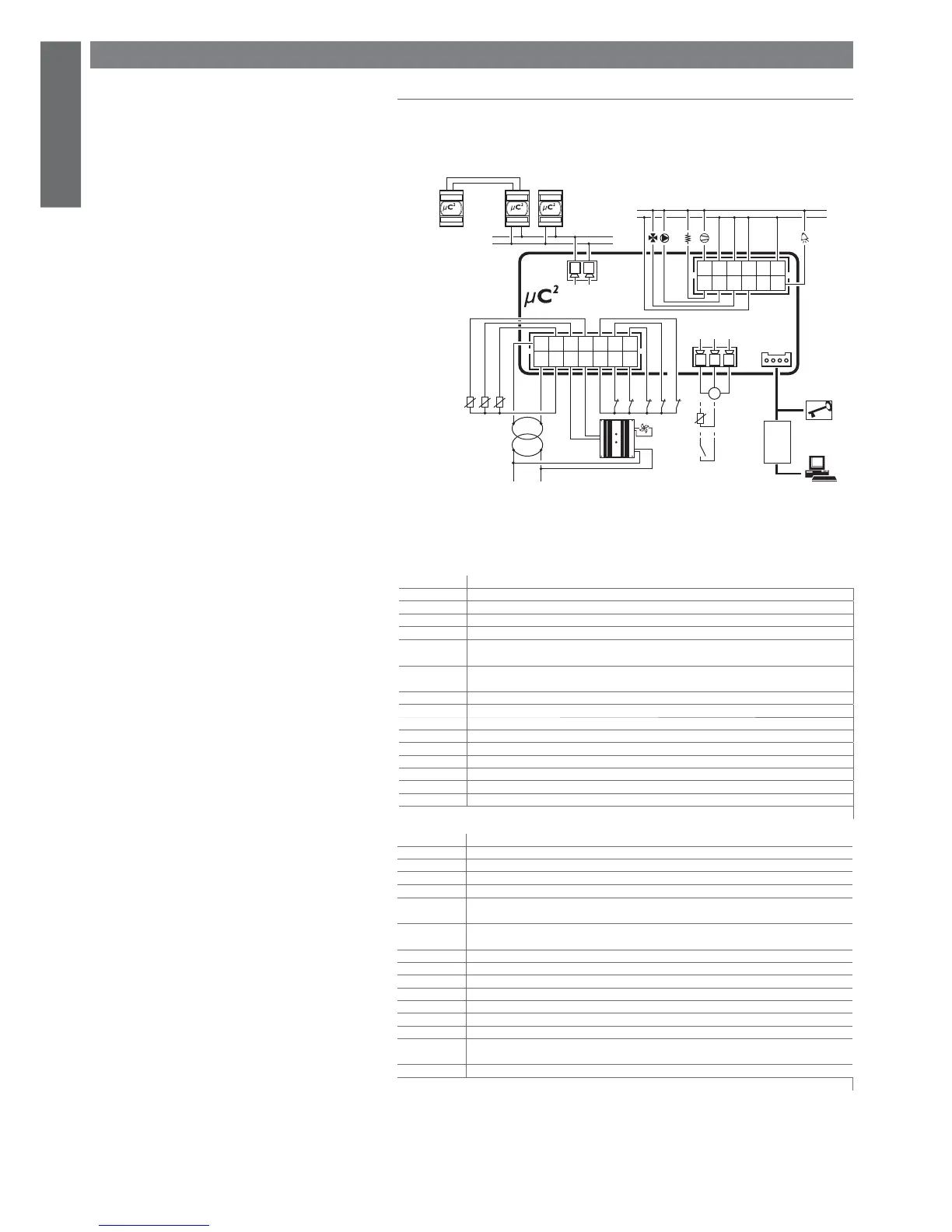

7. CONNECTIONS, ACCESSORIES AND OPTIONS

7.1 Connection diagram

Below is the connection diagram for the µC

2

SE.

Panel version

I/O layout

µC

2

SE Description

B1 Control probe (Evaporator inlet/ambient)

B2 Protection probe (evaporator outlet/outlet)

B3 Condenser/outside temperature probe

B4 ( universal) Condenser pressure probe

ID1* Flow switch – thermal overload circuit 1 – cooling/heating – end defrost circuit 1 – step 1

condensing unit – second set point

ID2* Flow switch – thermal overload 1 circuit – cooling/heating – end defrost circuit 1 – step 2

condensing unit – second set point

ID3 High pressure circuit 1

ID4 Low pressure circuit 1

ID5 Remote ON/OFF – reverse cycle condensing unit if reversible

Y1 Ramp circuit 1 (condenser)

C1/2-NO1 Compressor 1

C1/2-NO2 Heater or reversing valve in 1st circuit

C3/4-NO3 Fan 1/evaporator pump

C3/4-NO4 Compressor 2 (capacity-control compressor 1)

C5-NO5 Alarm or reversing valve

Table 7.a

Expansion Description

B5 Output probe in common with 2 evaporators (only with 2 circuits)

B6 Circuit 2 protection probe (2

nd

evaporator output)

B7 2

nd

condenser temperature probe

B8 ( universal) 2

nd

condenser pressure probe

ID6** Flow switch – thermal overload circuit 2 – end defrost circuit 2 – step 4 condensing unit –

second set point

ID7** Flow switch – thermal overload circuit 2 – end defrost circuit 2 – step 4 condensing unit– second

set point

ID8 High pressure circuit 2

ID9 Low pressure circuit 2

ID10

Y2 Ramp circuit 2 (condenser)

C6/7-NO6 Compressor 3 (1 in 2nd circuit)

C6/7-NO7 Heater or reversing valve in 2nd circuit

C8/9-NO8 Fan 2/condenser pump/backup

C8/9-NO9 Compressor 4 (capacity-control compressor 2) or reversing valve circuit 1 or reversing valve

circuit 2

C10-NO10 Warning or reversing valve circuit 2

Table 7.b

*= Any of the options for P08 can be selected (see Table 5.11)

**= Any of the options for P08 can be selected, except for E/I and E/I delay.

Fig. 7.a

Loading...

Loading...