µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

15

4.5 Compressors with different capacities

Parameter /02 is used to choose the option of compressors with different capacities.

This allows more load steps and therefore finer control.

Once the capacity of the individual compressors has been defined (parameters /03, /04, /05, /06), the software, based on the requirements of the installation and the

compressors available (without alarms or timers), will calculate the most suitable combination to satisfy the requirement. Whenever the requirement changes, the

software recalculates the most suitable combination. The combination will always be greater than or equal to the requirement.

If two compressors have the same capacity, the compressor with the lower index will always be the first to start.

4.5.1 Proportional band control with different capacity compressors

Based on the pressure, the set point and the differential, the software will proportionally calculate the capacity required to bring the pressure back near the set point.

At the set point plus differential the requirement will be at the maximum value, while it will be null for pressure values around or less than the set point.

alDifferenti

pressSetpointCapacityMax

requiredCapacity

)(_

_

−×

=

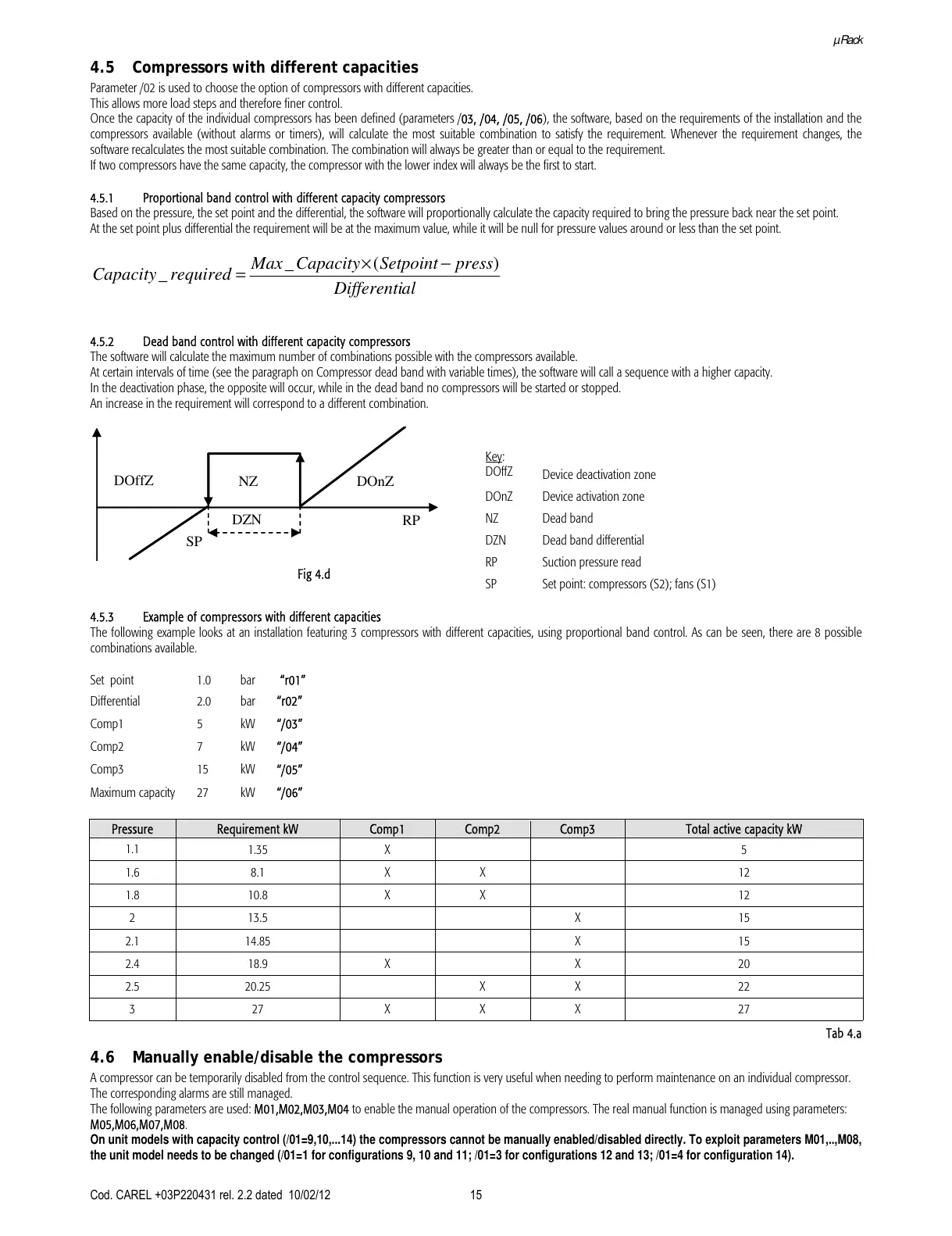

4.5.2 Dead band control with different capacity compressors

The software will calculate the maximum number of combinations possible with the compressors available.

At certain intervals of time (see the paragraph on Compressor dead band with variable times), the software will call a sequence with a higher capacity.

In the deactivation phase, the opposite will occur, while in the dead band no compressors will be started or stopped.

An increase in the requirement will correspond to a different combination.

Fig 4.d

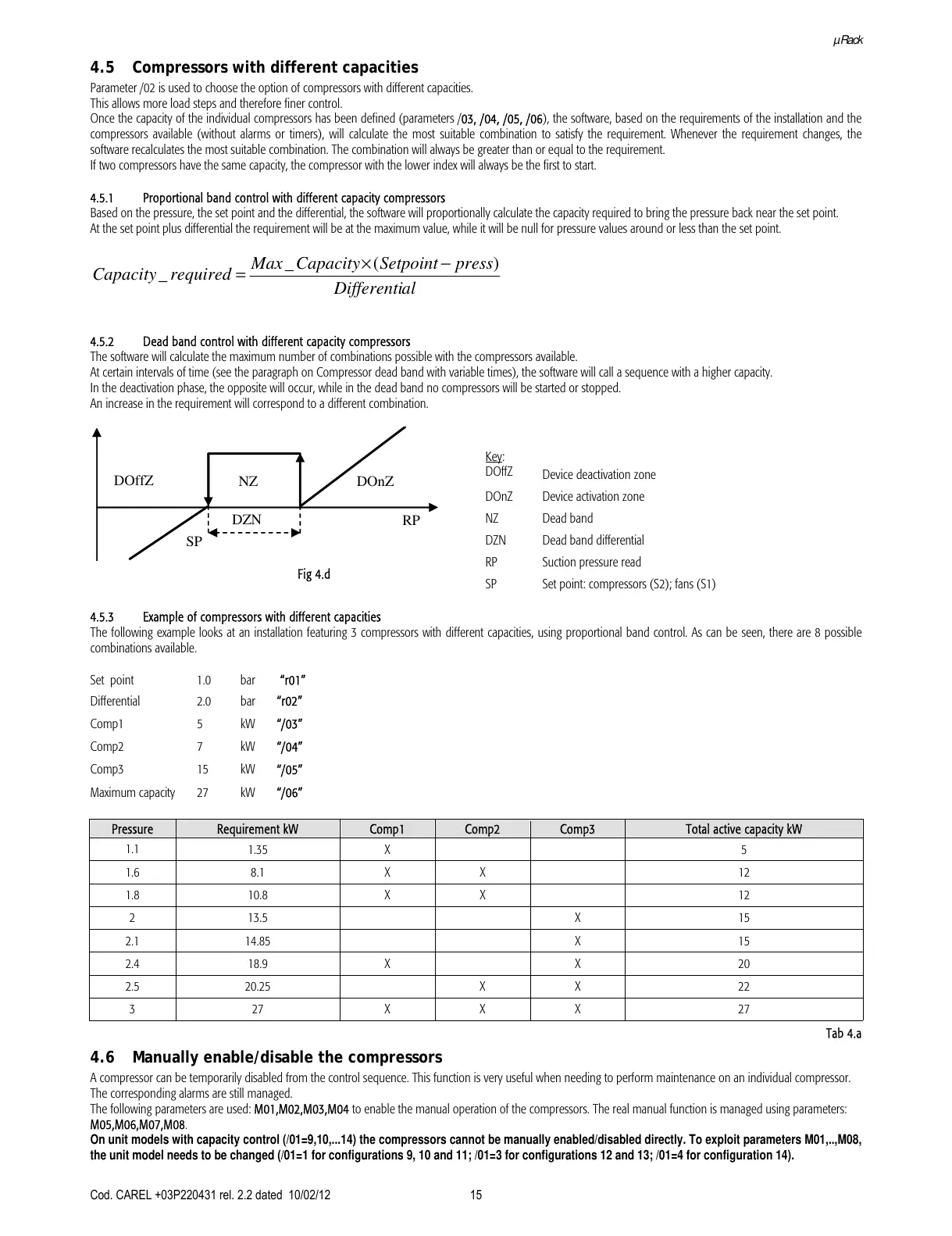

4.5.3 Example of compressors with different capacities

The following example looks at an installation featuring 3 compressors with different capacities, using proportional band control. As can be seen, there are 8 possible

combinations available.

Set point 1.0 bar

“r01”

Differential 2.0 bar “r02”

Comp1 5 kW “/03”

Comp2 7 kW “/04”

Comp3 15 kW “/05”

Maximum capacity 27 kW “/06”

Pressure Requirement kW Comp1 Comp2 Comp3 Total active capacity kW

1.1

1.35 X

5

1.6 8.1 X X 12

1.8 10.8 X X 12

2 13.5 X 15

2.1 14.85

X 15

2.4 18.9 X

X 20

2.5 20.25

X X 22

3 27 X X X 27

Tab 4.a

4.6 Manually enable/disable the compressors

A compressor can be temporarily disabled from the control sequence. This function is very useful when needing to perform maintenance on an individual compressor.

The corresponding alarms are still managed.

The following parameters are used: M01,M02,M03,M04 to enable the manual operation of the compressors. The real manual function is managed using parameters:

M05,M06,M07,M08.

On unit models with capacity control (/01=9,10,...14) the compressors cannot be manually enabled/disabled directly. To exploit parameters M01,..,M08,

the unit model needs to be changed (/01=1 for configurations 9, 10 and 11; /01=3 for configurations 12 and 13; /01=4 for configuration 14).

DOffZ

DOnZ

NZ

SP

DZN

RP

Key:

DOffZ

Device deactivation zone

DOnZ Device activation zone

NZ Dead band

DZN Dead band differential

RP Suction pressure read

SP Set point: compressors (S2); fans (S1)

Loading...

Loading...