ed), as shown in the photo here - as it is directly above the exhaust ducting and could be dam-

aged if you have any accidental wet-starts or similar.

Rudder

The rudder is cut loose, hinged and the dual phenolic con-

trol horns are installed at the factory, and you just need to

fit the rudder servo and linkage.

Servo Choice: Any standard sized minimum 8kg torque

digital servo will be OK for the rudder, but we highly rec-

ommend the JR8311 or 8411.

Centre the rudder servo using your R/C, and fit a plastic

HD (Heavy Duty) servo arm. Fit the rudder servo

(JR8311/8411/Futaba S9351) into the plywood servo

mount, with the output shaft towards the back end of the

servo, and screw into place with the 2.9Ø x 13mm sheet-

metal screws provided. As the servo is mounted inverted,

you should fit the brass eyelets upside-down into the rub-

ber grommets on the servo. Cut a small slot (5mm wide) in

the side of the fin in line with your servo output arm, and

lengthen this slot to suit the linkage later.

Glue the 50mm x 100m balsa plate across the fuselage

under the servo, and cover the plate with aluminium tape.

This will give the servo and extension cable some protec-

tion in the case of an accidental hot, or wet, start.

Make up the linkage using the M3 x 120mm all-thread,

steel clevise and nut at servo end, and the M3 ball-link,

and M3 x 16mm bolt and locknut to secure the ball-link

between the dual phenolic horns (see photo P2).

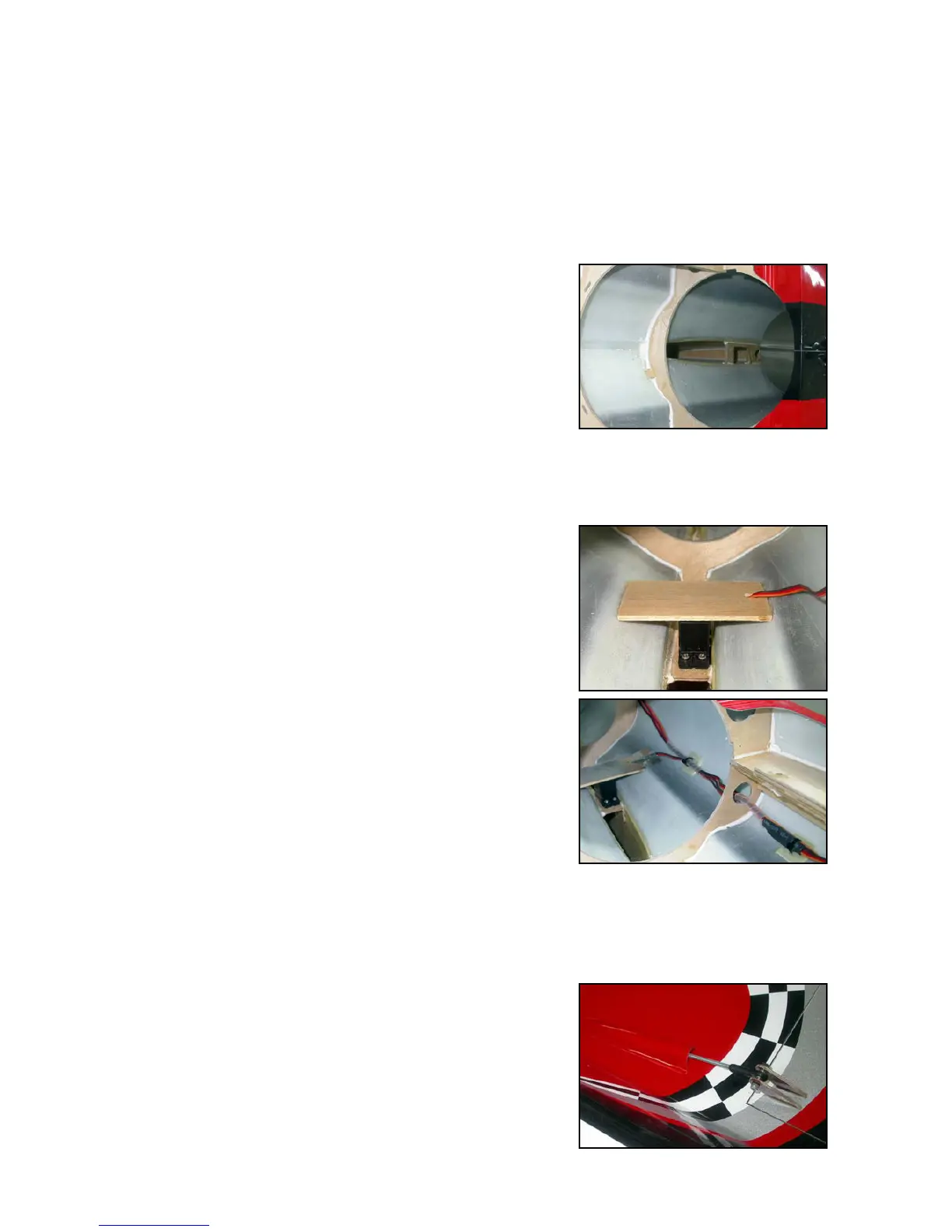

Supplied in the kit is plastic linkage fairing, pre-painted to

match the fin colour, which can be glued in place to cover

the linkage with a couple of drops of CA. (photo right).

Route the rudder and elevator servo extension cables

down one side of the fuselage, and the turbine cables and

fuel/propane tubes down the other side. Secure them so

that they cannot touch the thrust tube. Protect them with

spiral-wrap sleeves, or similar, where they pass through

plywood bulkheads, and especially when they pass

through fibreglass or carbon-fibre parts which could cut

through the cables or tubes in a few seconds.

10

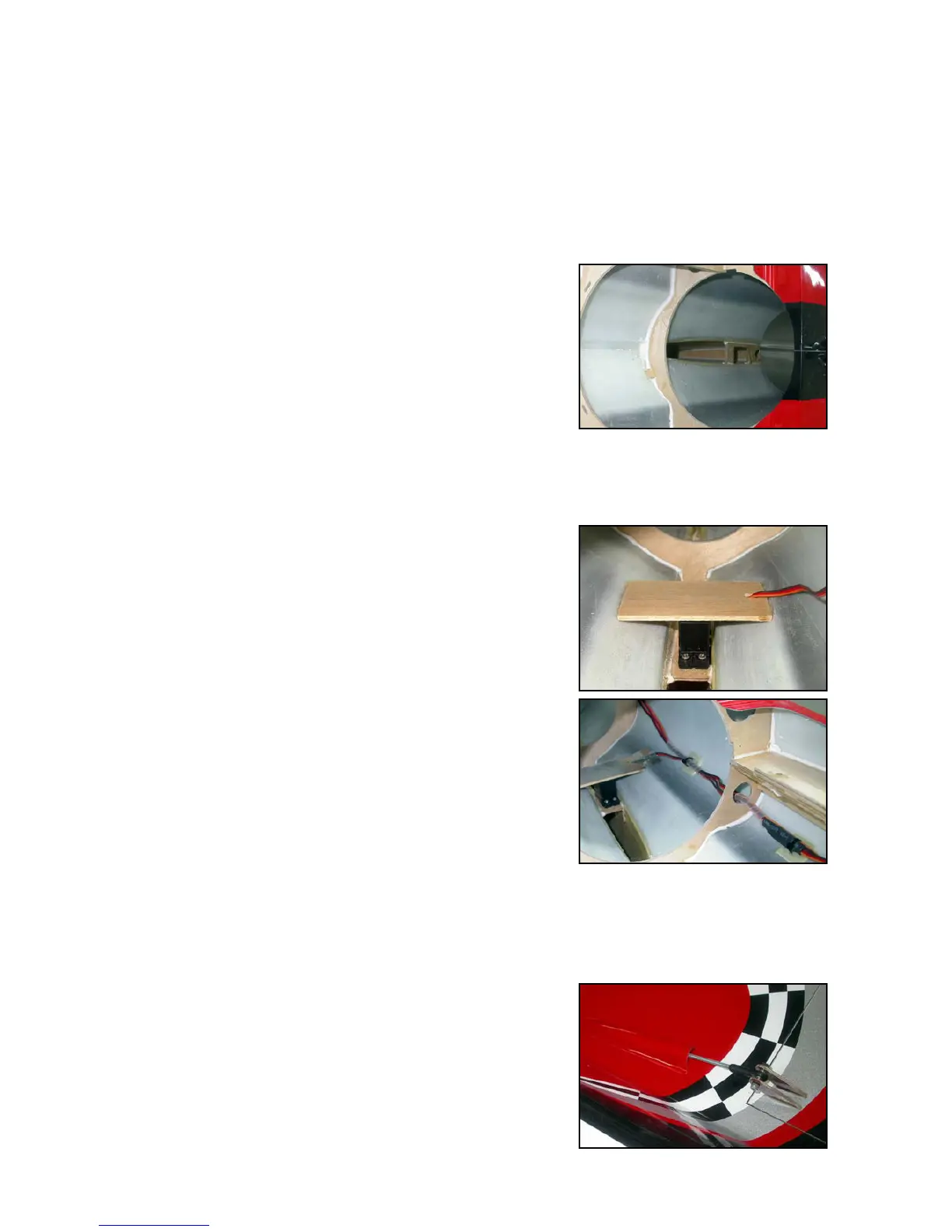

(above) Rudder servo mount is

installed for you at the factory.

(below) Servo installed with balsa

protection glued in position.

(above) Secure rudder & stab

servo extensions to fuselage.

Cover rudder servo plate with alu-

minium tape for heat protection.

(below) Rudder linkage fairing.

Loading...

Loading...