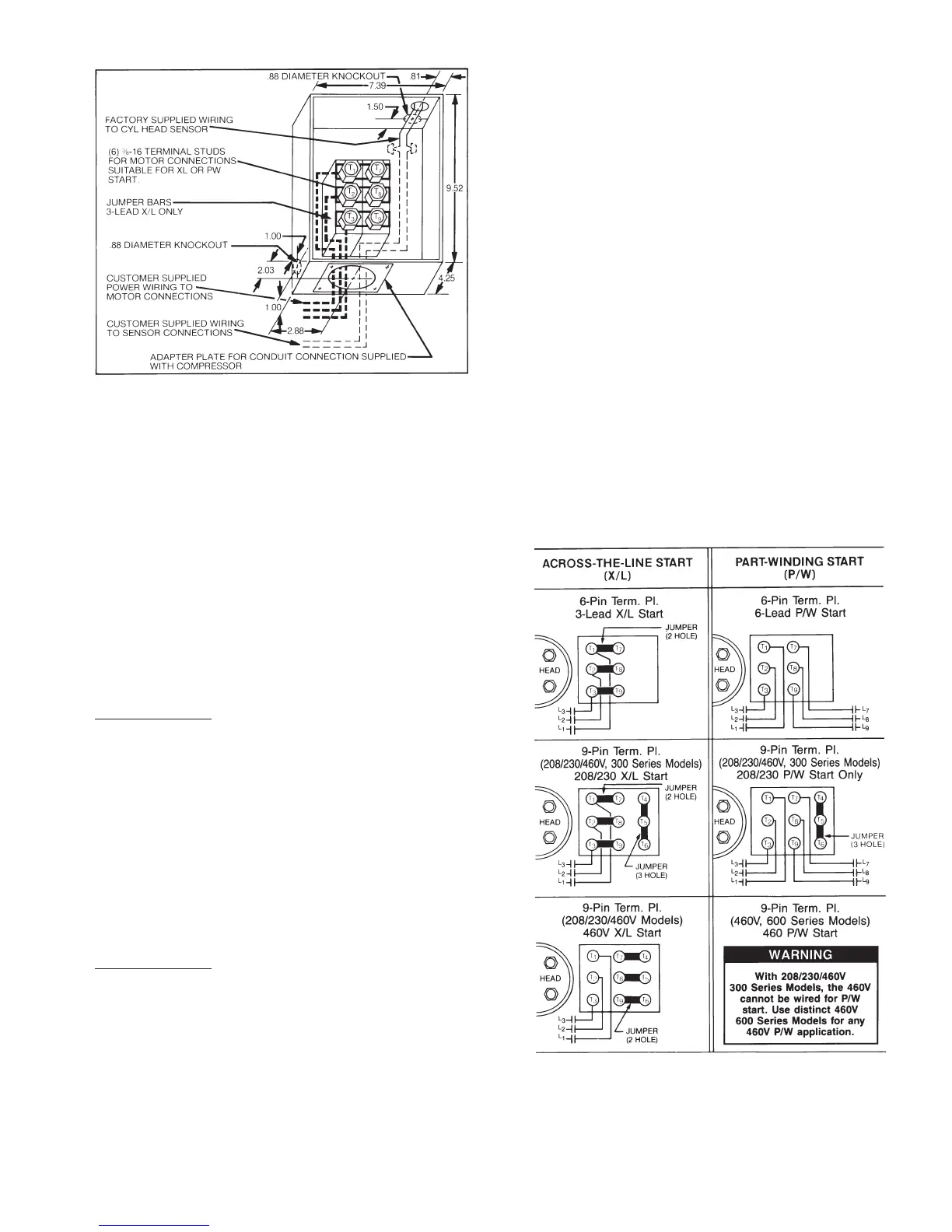

TERMINAL BOX

The compressor terminal box is supplied with 2 support plates to

mount the connector for the power wiring conduit. Select the one

support plate with the opening suitable for the size of the conduit

connector to be used and fasten it to the terminal box with the (4)

screws provided.

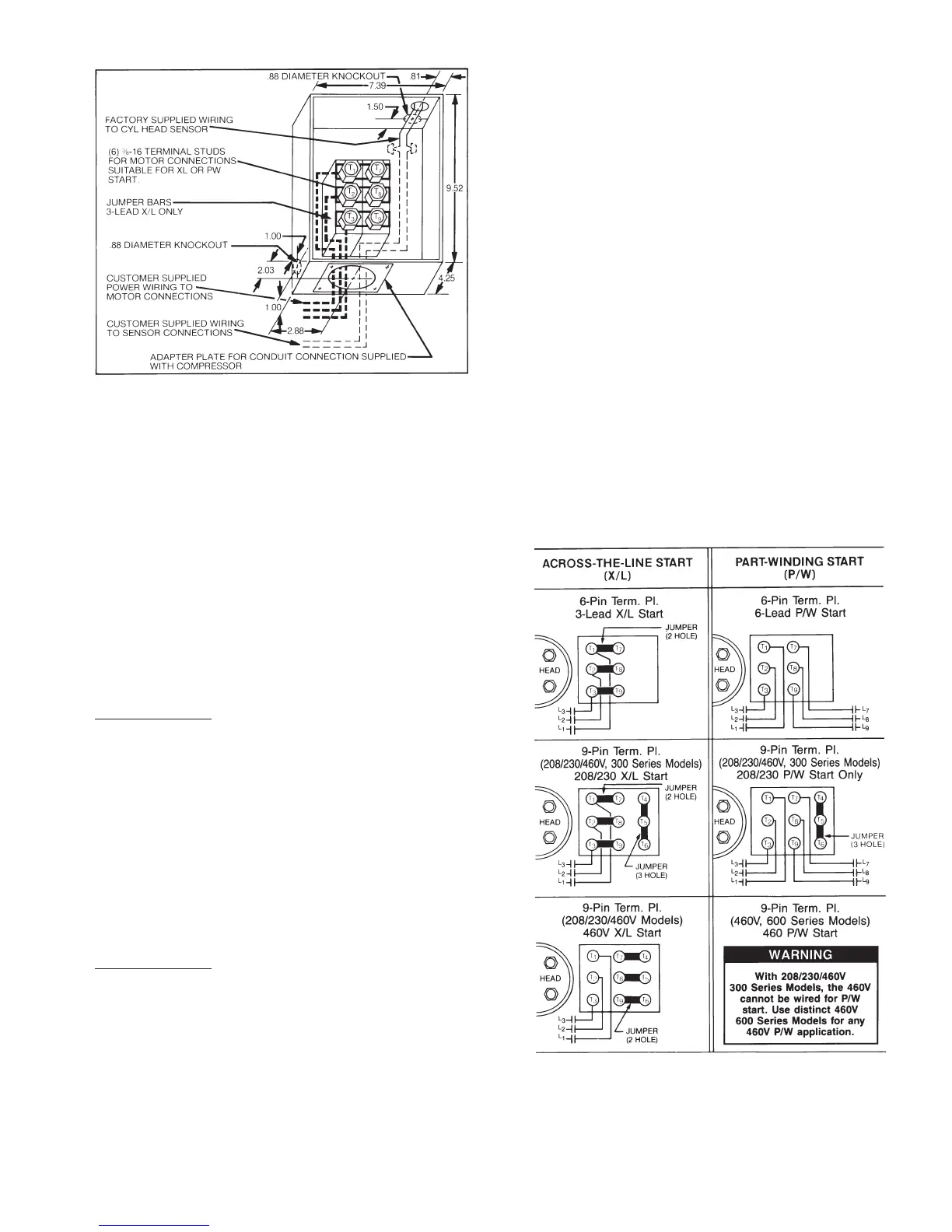

TERMINAL PLATE WIRING

The parts listed in item #4 (General Comments, pg. 1) are supplied

in parts bag with the compressor and are used when wiring the

terminal plate.

Customer supplied wiring to the compressor terminal plate must be

provided with insulated wire terminal connectors and be suitable for

accommodating the 3/8’’ diameter terminal studs.

6-Pin Terminal Plate

3-Lead Across-the-Line (X/L) Start (Fig. 3)

The (3) jumper bars supplied with the compressor are required for

3-Lead XL start only. Jumpers are assembled directly on terminal

studs connecting T1 & T7, T2 & T8 and T3 & T9. The 3 power leads

are to be assembled to the applicable terminal stud directly on top of

the jumper bar. Secure wire terminals and jumper bars to the termi-

nal studs with the (6) 3/8-16 jam nuts provided with the compressor.

Torque jam nuts to 12 lb-ft (16 n-m) maximum.

6-Lead Part Winding (P/W) Start (Fig. 3)

The 6 power leads are to be assembled and secured to the applicable

terminal studs with the (6) 3/8-6 jam nuts provided with the compres-

sor. Torque jam nuts to 12 lb-ft (16 n-m) maximum.

Note: Jumper bars are not required with 6-Lead X/L or P/W start

applications.

9-Pin Terminal Plate

208/230 V-3-60 or 200 V-3-50 Across-the-Line Start (Fig. 3)

1. Install (3) 2-hole copper jumper bars connecting terminals 1 to 7,

2 to 6, and 3 to 9.

2. Remove plastic connector block from terminals 4, 5 and 6.

3. Install the fl at connector block (non-conducting) on terminals 4,

5 and 6.

4. Reinstall terminal nuts on terminals 4, 5 and 6 (removed in

step #2).

5. Install the 3-hole copper jumper bar connecting terminals 4, 5

and 6.

6. Connect the line leads to terminals 1, 2 and 3.

7. Install (9) terminal nuts (included in this kit) on terminal studs to

secure jumper bar/line connections. Tighten terminal nuts to 12 ft-lbs

(16 n-m) maximum.

208/230 V-3-60 or 200 V-3-50 Part Winding Start (Fig. 3)

1. Remove plastic connector block from terminals 4, 5 and 6.

2. Install the fl at connector block (non-conducting) on terminals 4,

5 and 6.

3. Re-install terminal nuts on terminals 4, 5 and 6 (removed in

step #1).

4. Install the 3-hole copper jumper bar connecting terminals 4, 5

and 6.

5. Connect the line leads to terminals 1, 2, 3, 7, 8 and 9.

6. Install (9) terminal nuts (included in this kit) on terminal studs to

secure jumper bar/line connections. Tighten terminal nuts to 12 ft-lbs

(16 n-m) maximum.

460 V-3-60 or 400 V-3-50 Across-the-Line Start (Fig. 3)

1. Install (3) 2-hole copper jumper bars connecting terminals 7 to 4,

8 to 5, and 9 to 6.

2. Connect the line leads to terminals 1, 2 and 3.

3. Install (9) terminal nuts (included in this kit) on terminal studs to

secure jumper bar/line connections. Tighten terminal nuts to 12 ft-lbs

(16 n-m) maximum.

Figure A

Terminal Box Arrangement

Figure 3

Terminal Plate Wiring

Loading...

Loading...