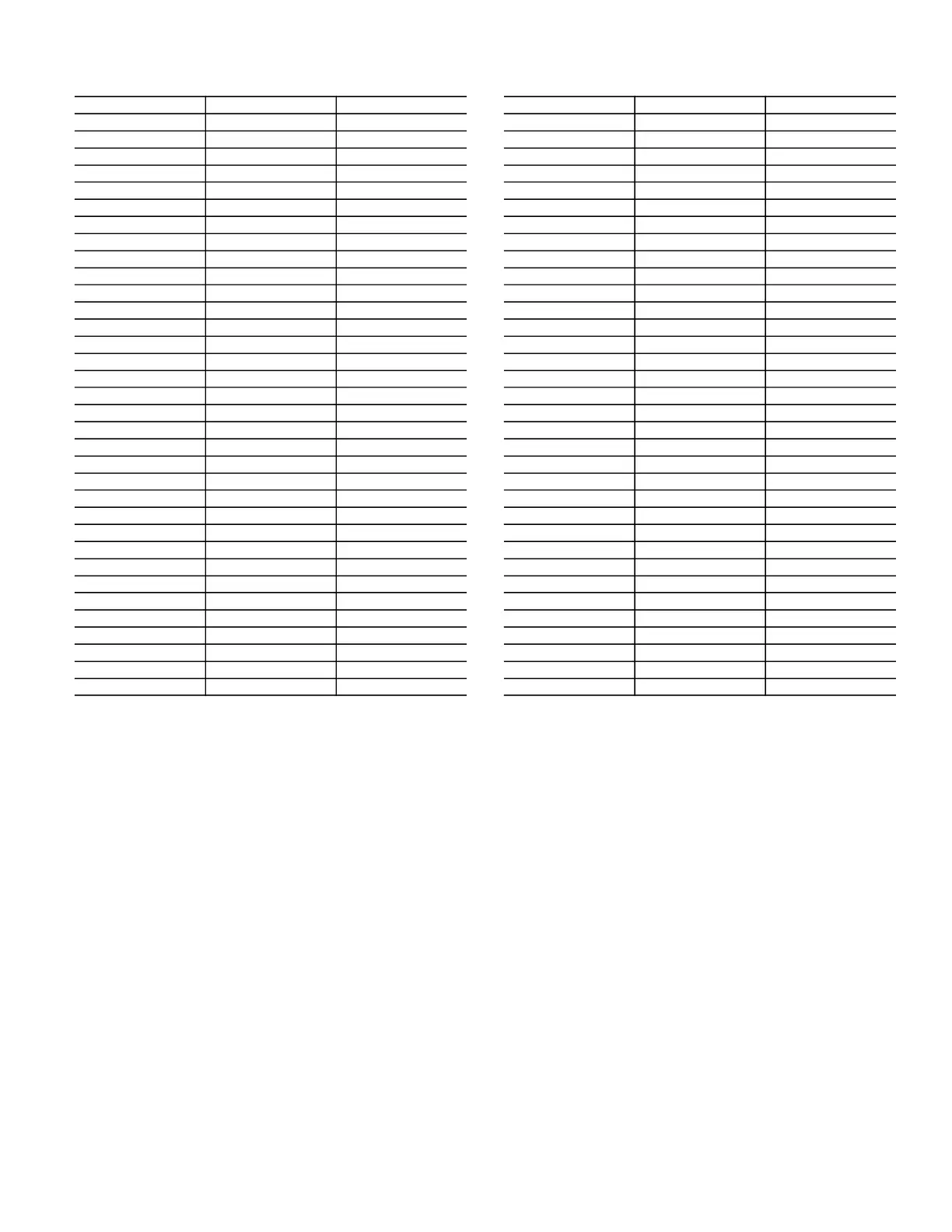

59

181 83 570

183 84 552

185 85 535

187 86 518

189 87 502

190 88 487

192 89 472

194 90 458

196 91 444

198 92 431

199 93 418

201 94 405

203 95 393

205 96 382

207 97 370

208 98 360

210 99 349

212 100 339

214 101 329

216 102 320

217 103 311

219 104 302

221 105 293

223 106 285

225 107 277

226 108 269

228 109 262

230 110 255

232 111 248

234 112 241

235 113 234

237 114 228

239 115 222

241 116 216

Table 18 — 5K Thermistor Temperature vs.

Resistance (cont)

°F °C RESISTANCE, OHMS

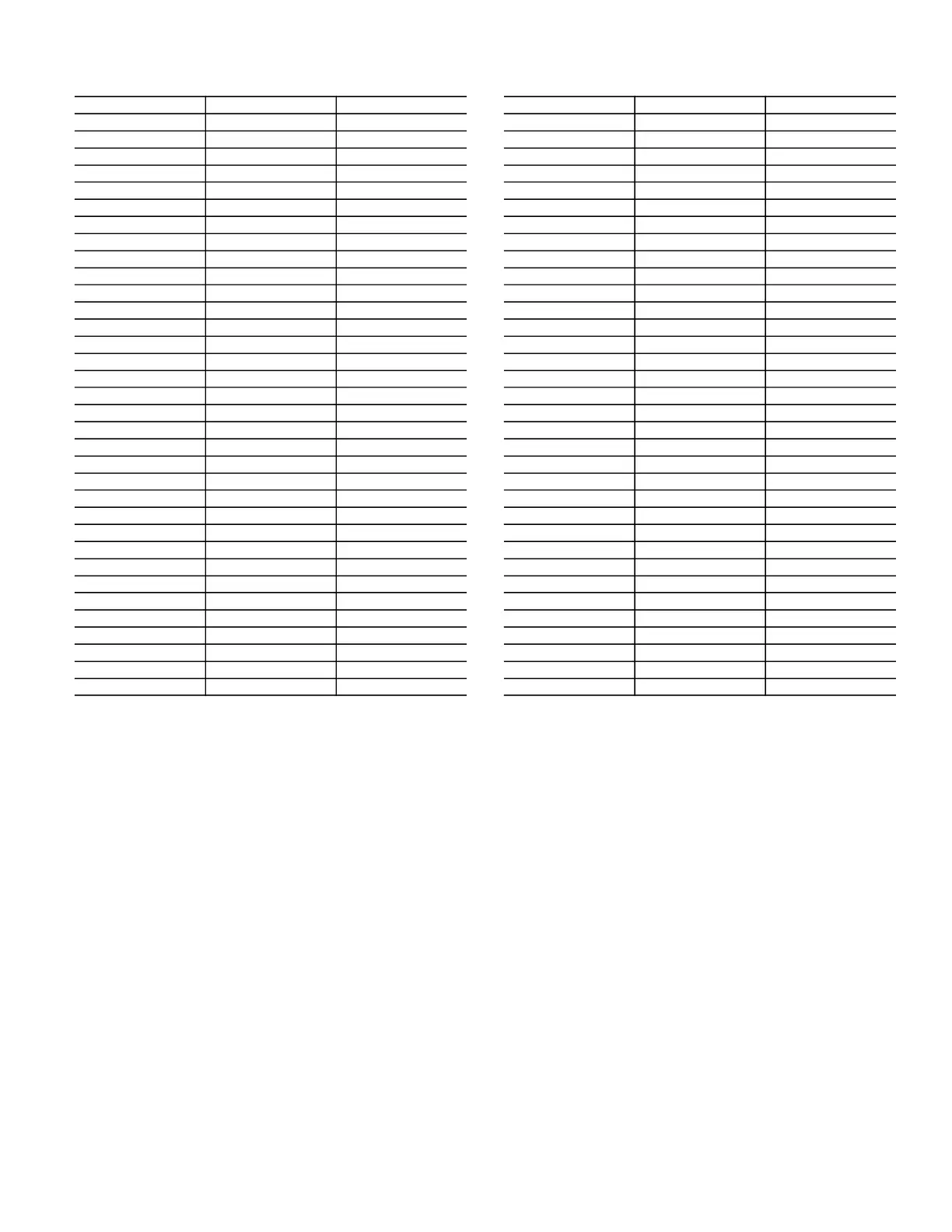

243 117 210

244 118 205

246 119 199

248 120 194

250 121 189

252 122 184

253 123 179

255 124 175

257 125 170

259 126 166

261 127 162

262 128 157

264 129 154

266 130 150

268 131 146

270 132 142

271 133 139

273 134 135

275 135 132

277 136 129

279 137 126

280 138 123

282 139 120

284 140 117

286 141 114

288 142 111

289 143 109

291 144 106

293 145 104

295 146 101

297 147 99

298 148 97

300 149 94

302 150 92

Table 18 — 5K Thermistor Temperature vs.

Resistance (cont)

°F °C RESISTANCE, OHMS

If a more accurate check is required, unit must be shut down and

thermistor removed and checked at a known temperature (freezing

point or boiling point of water) using either voltage drop measured

across thermistor at the J3 terminal, by determining the resistance

with unit shut down and thermistor disconnected from J3. Com-

pare the values determined with the value read by the control in

the Temperatures mode using the controller display.

Fan Blade and Fan Motor Service

A formed metal mount bolted to the coil caps supports each fan

and motor assembly. A shroud and a wire grille provide protection

from the rotating fan. See Figure 46. To remove the fan a special

puller (RCD part no. 30RB680082) can be used. The fan utilizes a

set screw and does not require the use of retaining compound in

the keyway. The fan can be removed without the puller, but its use

eases disassembly. The exposed end of the fan motor shaft is pro-

tected from weather by grease. If fan motor must be removed for

service or replacement, re-grease the fan shaft. The fan needs to be

positioned fully down against the step on the motor shaft. Apply

blue thread locker (Loctite 243) to the threads of both the axial bolt

and the set screw. Install the thick washer and M8 axial bolt; do

not fully tighten. Install set screw and tighten to 16 ± 2 ft-lbs (21.7

± 2.7 Nm). Torque the axial bolt to 24 ± 2 ft-lbs (32.5 ± 2.7 Nm).

Reinstall shroud and wire grille.

Loading...

Loading...