Rigging 2-Piece Units— Two-piece units consist of all units

from 054-068 and, when specified, units 041-047. Refer to

the following procedure for rigging.

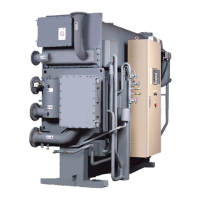

1. Absorber-evaporator assembly — Lift the absorber-

evaporator assembly from lift lugs at each end of ma-

chine. Refer to Fig. 1.

2. Generator-condenser assembly

a. Lift with cable slings placed under condenser water

boxes. Refer to Fig. 1.

b. Place generator-condenser assembly on top of absorber-

evaporator assembly.

c. Align the match marks stamped on one leg of each

generator-condenser and absorber-evaporator assem-

blies.

d. Make sure stamped serial numbers accompanying the

match marks correspond on both assemblies.

POSITION AND LEVEL THE EQUIPMENT — Isolation

pads are not necessary for most installations. However, for

cases where isolation pads are required, refer to Fig. 3 and

Table 3 for installation data.

It is not necessary to level the generator-condenser as-

sembly as both assemblies are designed to be level when the

absorber-evaporator assembly has been leveled.

The 16JB machine must be level within

1

⁄

4

in. per 20 ft,

both lengthwise and diagonally. To level the machine, pro-

ceed as follows:

1. Fill 50-ft length of clear flexible tubing completely with

water.

2. Use water gage and leveling reference points stamped on

absorber-evaporator shell to level machine. Leveling marks

on evaporator shell are covered by small removable one-

in. squares of insulation.

3. Level machine with shims until requirements are met. If

isolation assembly is used, shim under the soleplate.

ASSEMBLE 2-PIECE UNIT — Assemble 2-piece unit (see

procedure below). Then leak test and evacuate machine as

described in Leak Test and Machine Evacuation Procedures.

a. Bolt leg assemblies.

b. Weld the piping connections and make sure weld con-

nections are vacuum tight.

If chiller is assembled before it is rigged, do not lift ma-

chine under condenser water boxes to avoid damage to

machine. Machine should be lifted using lift lugs lo-

cated at each end of the machine.

Table 3 — Isolation Pad

and Soleplate Specifications

UNIT

16JB

NO. (EACH)

OF PADS AND

SOLEPLATES

DIMENSIONS

(in.)

DIMENSIONS

(mm)

Pad Soleplate Pad Soleplate

010

012

014

4 9 x 6.4 10 x 7.5 228 x 162 254 x 191

018

021

4 9 x 10.4 10 x 11.5 228 x 263 254 x 292

024

028

4 9 x 12.4 10 x 13.5 228 x 315 254 x 343

032

036

4 9 x 14.4 10 x 15.5 228 x 365 254 x 394

041

047

4 9 x 18.4 10 x 19.5 228 x 465 254 x 495

054

057

4 12 x 18.4 13 x 19.5 305 x 465 331 x 495

061

068

4 14 x 18.4 15 x 19.5 356 x 465 381 x 495

NOTE: Higher isolation efficiencies may be obtained with double-

layer pads. Double-layer pads, factory-fused together, are available

from various manufacturers. If 2 single-layer pads are used, a metal

divider equal to pad dimensions should be inserted between layers.

MACHINE LEAKTEST —All field-weld joints on the chiller

must be leak tested prior to starting the machine. Leak test

as follows:

1. Close all pump service valves, auxiliary evacuation valve

(Fig. 4) and purge exhaust valve (Fig. 5).

2. Refer to Table 4 for amount of refrigerant and nitrogen

required for leak testing.

3. If machine is under vacuum, bring to atmospheric pres-

sure with dry air or dry nitrogen.

4. Pressurize to 8 psig with Refrigerant 22. Charge through

auxiliary evacuation valve (item 9, Fig. 1).

5. Increase the machine pressure to 20 psig with dry air or

dry nitrogen.

Exceeding 20 psi will cause severe damage to chiller.

NOTES:

1. If optional shipping rails are on unit, be sure only the machine

base is on the isolation pad at each corner.

2. Shim under soleplate if necessary to level machine.

Fig. 3 — Typical Isolation Assembly

Fig. 4 — Auxiliary Evacuation Device

4

Loading...

Loading...