7

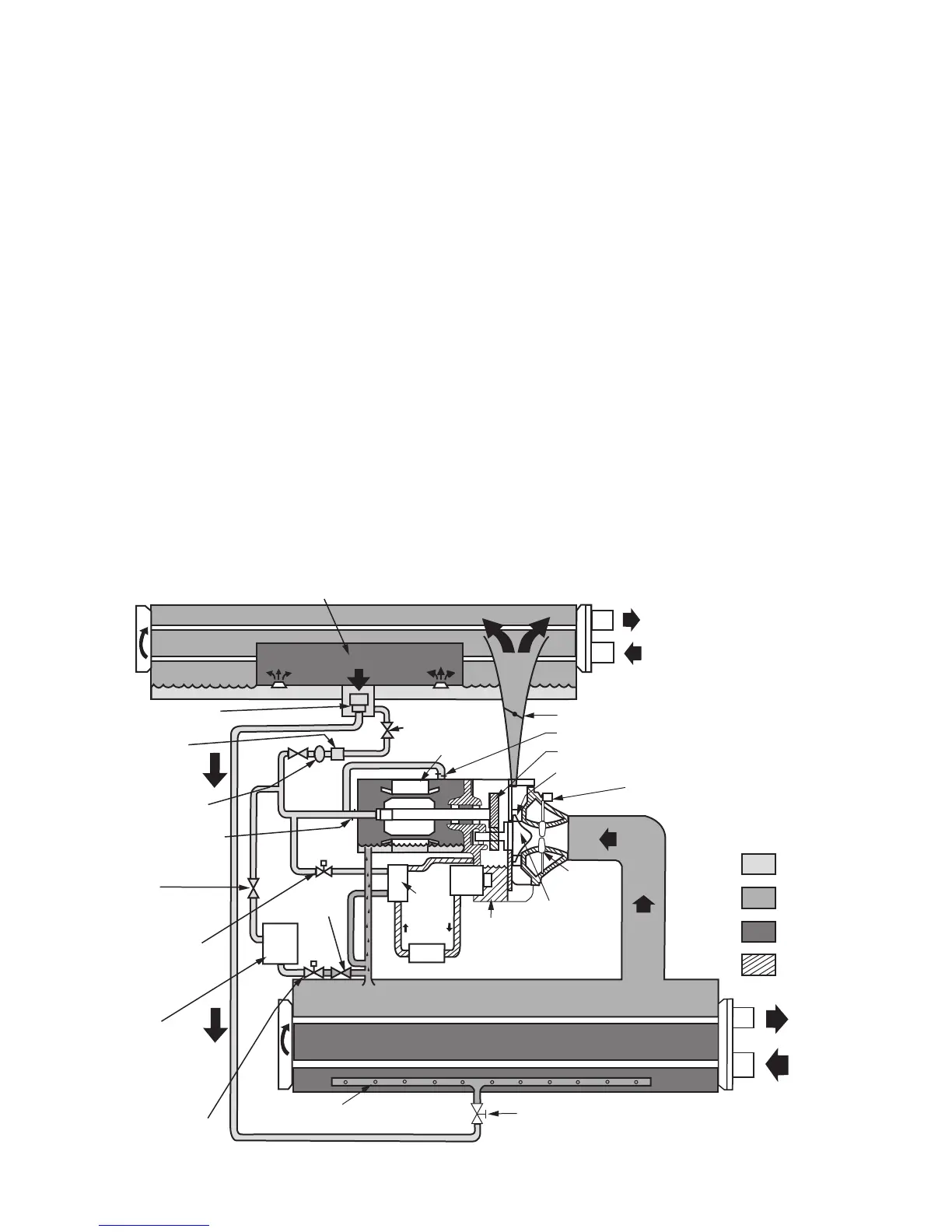

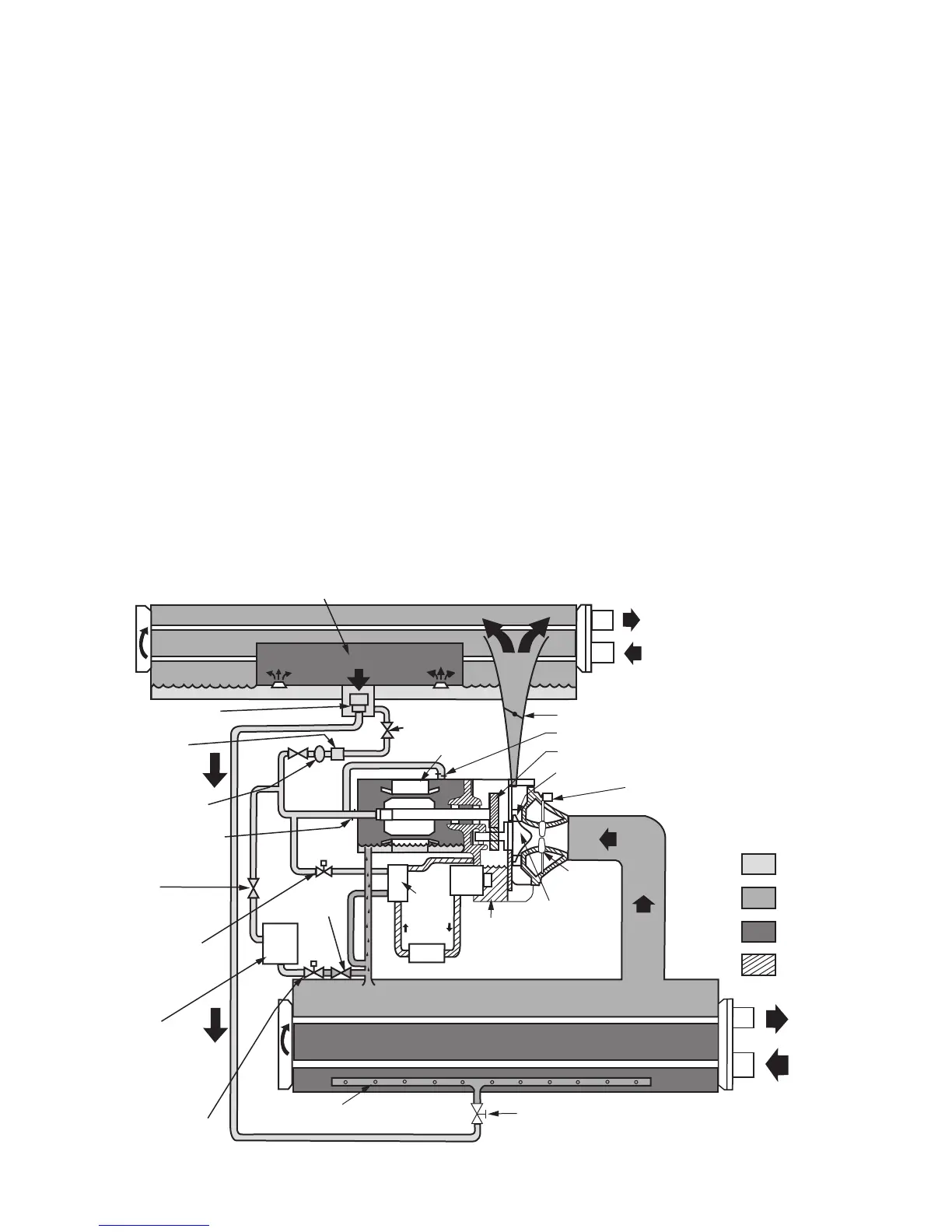

REFRIGERATION CYCLE

The compressor continuously draws refrigerant vapor from

the cooler at a rate set by the amount of guide vane opening or

compressor speed. As the compressor suction reduces the

pressure in the cooler, the remaining refrigerant boils at a fairly

low temperature (typically 38 to 42 F [3 to 6 C]). The energy

required for boiling is obtained from the water flowing through

the cooler tubes. With heat energy removed, the water becomes

cold enough to use in an air conditioning circuit or for process

liquid cooling.

After taking heat from the water, the refrigerant vapor is

compressed. Compression adds still more heat energy, and the

refrigerant is quite warm (typically 98 to 102 F [37 to 40 C])

when it is discharged from the compressor into the condenser.

Relatively cool (typically 65 to 90 F [18 to 32 C]) water

flowing into the condenser tubes removes heat from the refrig-

erant and the vapor condenses to liquid.

The liquid refrigerant passes through orifices into the

FLASC (Flash Subcooler) chamber (Fig. 3). Since the FLASC

chamber is at a lower pressure, part of the liquid refrigerant

flashes to vapor, thereby cooling the remaining liquid. The

FLASC vapor is recondensed on the tubes which are cooled by

entering condenser water. The liquid drains into a float cham-

ber between the FLASC chamber and cooler. Here, a float

valve forms a liquid seal to keep FLASC chamber vapor from

entering the cooler. When liquid refrigerant passes through the

valve, some of it flashes to vapor in the reduced pressure on the

cooler side. In flashing, it removes heat from the remaining

liquid. The refrigerant is now at a temperature and pressure at

which the cycle began.

MOTOR AND LUBRICATING OIL

COOLING CYCLE

The motor and the lubricating oil are cooled by liquid re-

frigerant taken from the bottom of the condenser vessel

(Fig. 3). Refrigerant flow is maintained by the pressure differ-

ential that exists due to compressor operation. After the refrig-

erant flows past an isolation valve, an in-line filter, and a sight

glass/moisture indicator, the flow is split between the motor

cooling and oil cooling systems.

Flow to the motor cooling system passes through an orifice

and into the motor. Once past the orifice, the refrigerant is

directed over the motor by a spray nozzle. The refrigerant

collects in the bottom of the motor casing and is then drained

back into the cooler through the motor refrigerant drain line.

An orifice (in the motor shell) maintains a higher pressure in

the motor shell than in the cooler. The motor is protected by a

temperature sensor imbedded in the stator windings. An

increase in motor winding temperature past the motor override

set point overrides the temperature capacity control to hold,

and if the motor temperature rises 10° F (5.5° C) above this set

point, closes the inlet guide vanes. If the temperature rises

above the safety limit, the compressor shuts down.

Refrigerant that flows to the oil cooling system is regulated

by thermostatic expansion valves (TXVs). The TXVs regulate

flow into the oil/refrigerant plate and frame-type heat exchang-

er (the oil cooler in Fig. 3). The expansion valve bulbs control

oil temperature to the bearings. The refrigerant leaving the oil

cooler heat exchanger returns to the chiller cooler.

UNIT

MOUNTED

VFD

(VARIABLE

FREQUENCY

DRIVE)

HEAT

EXCHANGER

THERMOSTATIC

EXPANSION

VALVE

(TXV)

ORIFICE

FITTING

MOISTURE/

FLOW

INDICATOR

FILTER

DRIER

FLOAT VALVE

CHAMBER

REFRIGERANT

COOLING

ISOLATION VALVE

MOTOR

CONDENSER ISOLATION VALVE (OPTION)

ORIFICE FITTING

TRANSMISSION

DIFFUSER

GUIDE VANE

MOTOR

GUIDE

VANES

IMPELLER

FLASC CHAMBER

CONDENSER

CONDENSER

WATER

STATOR

ROTOR

OIL

PUMP

COMPRESSOR

COOLER ISOLATION

VALVE (OPTION)

DISTRIBUTION

PIPE

REFRIGERANT

LIQUID

REFRIGERANT

VAPOR

REFRIGERANT

LIQUID/VAPOR

OIL

CHILLED

WATER

OIL

COOLER

OIL

FILTER

VFD COOLING

SOLENOID

VFD

COOLING

ISOLATION

VALVE

VFD

COOLING

ISOLATION

VALVE

Fig. 3 — Refrigerant Motor Cooling and Oil Cooling Cycles

a19-1601

Loading...

Loading...