11

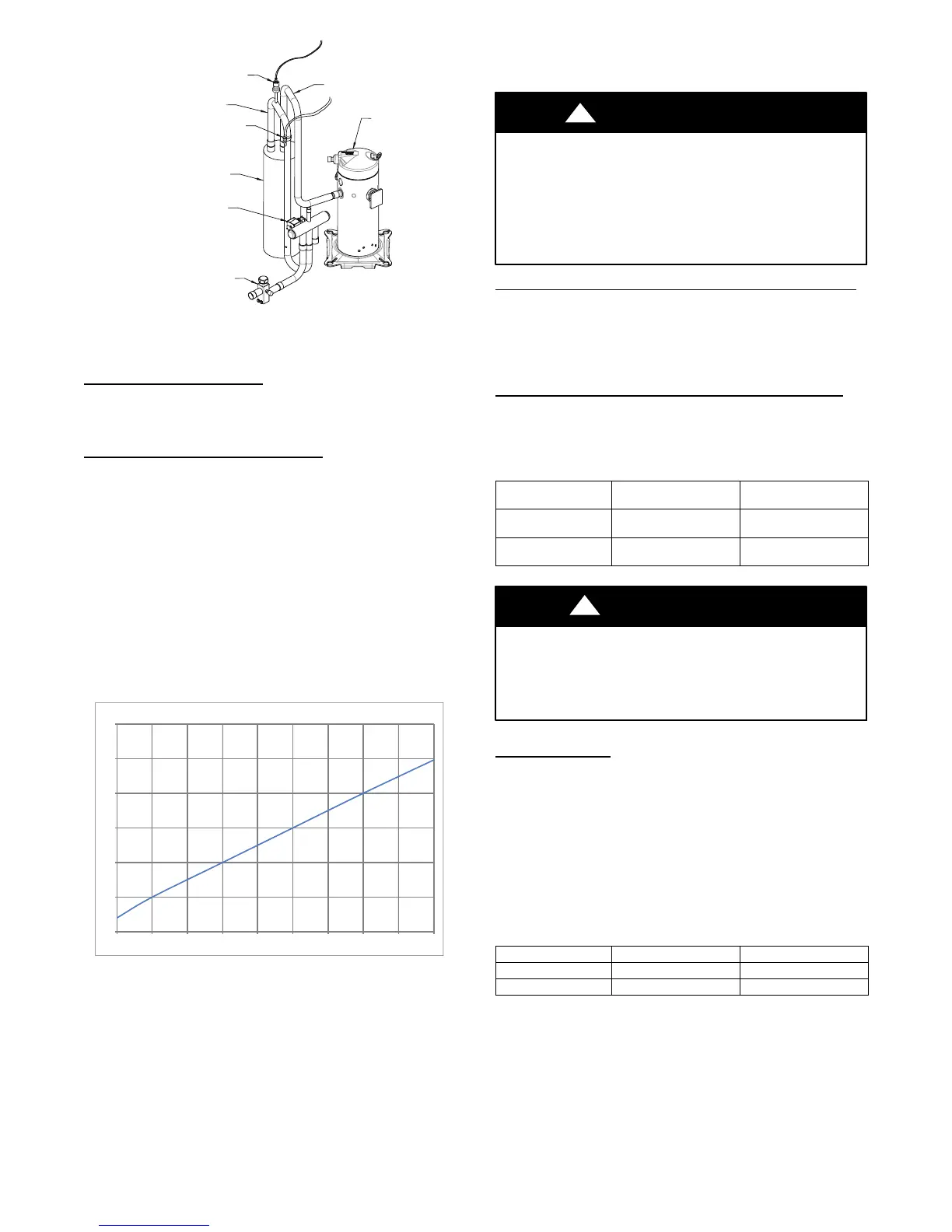

REVERSING VALVE

ACCUMULATOR

SUCTION TUBE

SUCTION THERMISTOR (OST)

SUCTION SERVICE VALVE

ACCUMULATOR TUBE

COMPRESSOR

PRESSURE TRANSDUCER (SPT)

A11103

Fig. 10 – Suction Thermistor (OST) Attachment

(On Suction Tube)

Suction Thermistor (OST)

Suction Thermistor is used for assisting in EXV control and must

be secured on the suction tube and aligned longitudinally to the

vertical surface of the tube axis (see Fig. 10).

Suction Pressure Transducer (SPT)

If the accuracy of the transducer is questioned, the technician can

check it while it is attached to the VSHP board. Connect a gage

manifold to the suction valve gage port fitting.

At the VSHP board, with the wire harness receptacle exposing a

portion of the three pins on the VSHP board, a DC voltmeter can

read the DC voltage between ground and supply (input) terminal.

Ensure that the input voltage is 5 VDC. Next, read the DC voltage

across the ground and output terminal. Record the output voltage.

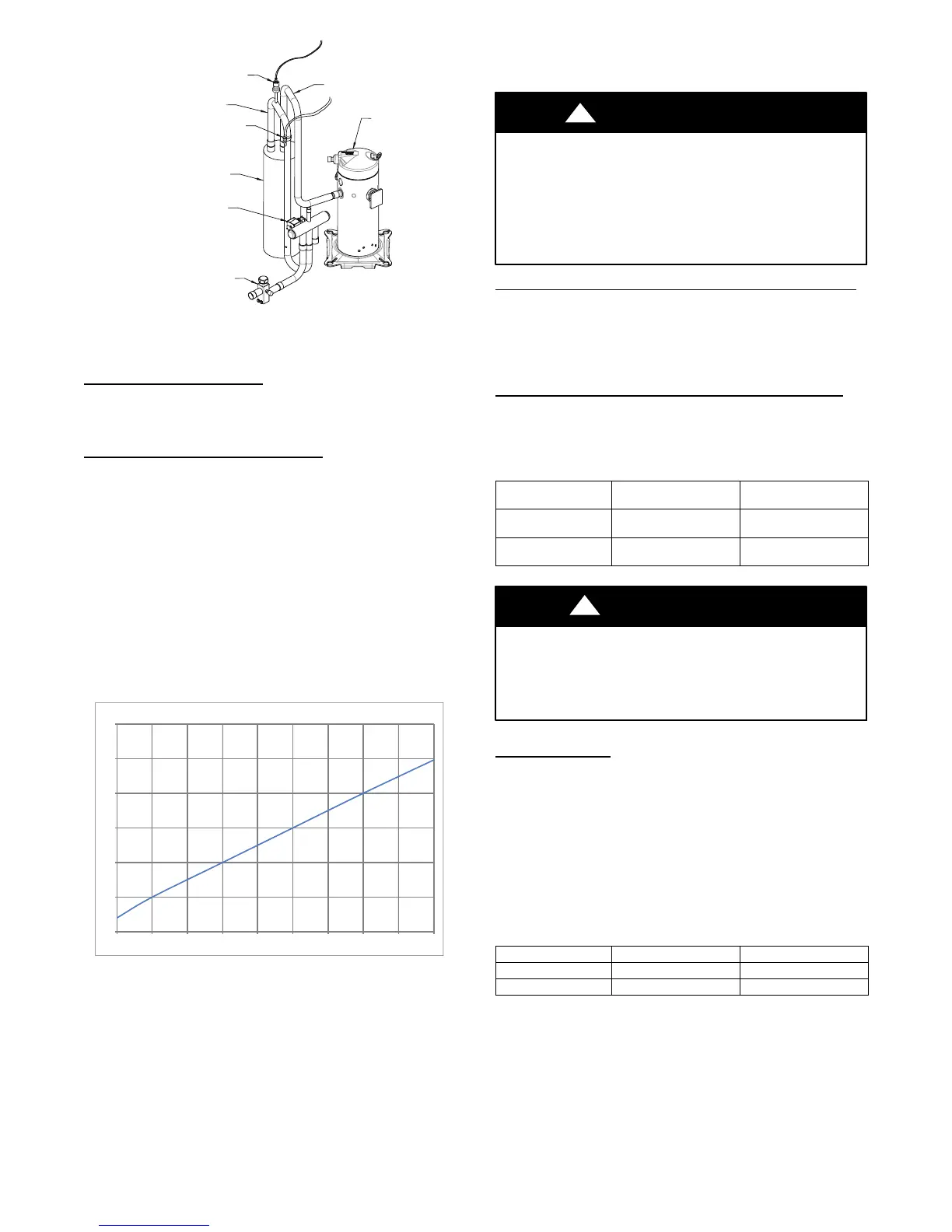

The suction pressure that the pressure transducer is reading can be

calculated by taking the output voltage and subtracting 0.5 from it

then taking that difference and multiplying it by 50. Pressure

(psig) = 50.0 x (DCV out -- 0.5). For example, if the measured

voltage is 3.0 VDC: 50 X (3.0 -- 0.5) -- 50 X 2.5 = 125 psig. See

Fig. 11.

0

1

2

3

4

5

6

0 25 50 75 100 125 150 175 200 225

Pressure - Sealed Gauge (psi)

A12035

Fig. 11 – Suction Pressure Transducer (SPT)

Output Funtion Graph

This can then be compared to the actual suction pressure from the

gage manifold.

In the event of a low pressure trip or low pressure lockout , check

the refrigerant for an under charge. If the charge is found to be

correct, check for low indoor airflow in cooling and the outdoor

fan for proper operation in heating and outdoor coil in heating for

airflow restrictions. Keep in mind that the outdoor fan motor may

run normally until it heats up.

Cool: PSUCT < 55 psig (for 3 minutes)

Heat: PSUCT < 23 psig (for 3 minutes)

PSUCT < 13 psig (instantaneous)

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

In order to minimize the ambient influence, make sure the

thermistor curved surface hugs the pipe surface and is

secured tight using the wire tie fished through the original

slot insulating polymer body.

Variable Speed Compressor Sensor Output Terminals

This compressor has a motor thermistor and a scroll thermistor.

Correct resistance between scroll thermistor terminal and common

is 10k at 77_F(25_C). Correct resistance between motor

thermistor terminal and common is 5k at 77_F(25_C). See Table

7.

Variable Speed Compressor Power Input Terminals

This compressor operates with a 3--phase variable frequency PWM

variable voltage to the three fusite terminals.

Table 3—Variable Speed Compressor Resistances

(winding resistance at 70_F 20_F)

WINDING

25VNA024

25VNA036

25VNA048

25VNA060

Between terminals

T1, T2, and T3

.681 .203

Between terminal &

ground

>1 mega OHM >1 mega OHM

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

and/or improper operation.

Do not use Meggar for measuring the winding resistance.

CAUTION

!

ECM Fan Motor

If verification of proper operation is required for the ECM motor

used in this unit, follow these steps:

1. Verify that the 230v input to the transformer is present.

2. Verify that the control board is powered 18 volts to 30 volts

from the transformer.

3. With the UI in charging mode in cooling, measure the DC

voltage between the PWM 1 and PWM 2 terminals on the

outdoor control board. The DC voltage and PWM (option-

al) measured must be as shown in Table 4.

Table 4—DC Voltage and PWM Measurement

Unit Size Voltage PWM

024, 036 8.9 VDC 52

048, 060 11.1 VDC 84

Loading...

Loading...