38MURA: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

12

g. Turn the handle of the flaring tool clockwise until the pipe is fully

flared. Flare the pipe in accordance with the dimensions in Table 8.

Fig. 15 — Flare Shape

Table 8 — Tightening Torque

NOTE: Use both a backup wrench and a torque wrench when

connecting or disconnecting pipes to or from the unit.

h. Remove the flaring tool and flare block, then inspect the end of

the pipe for cracks and even flaring.

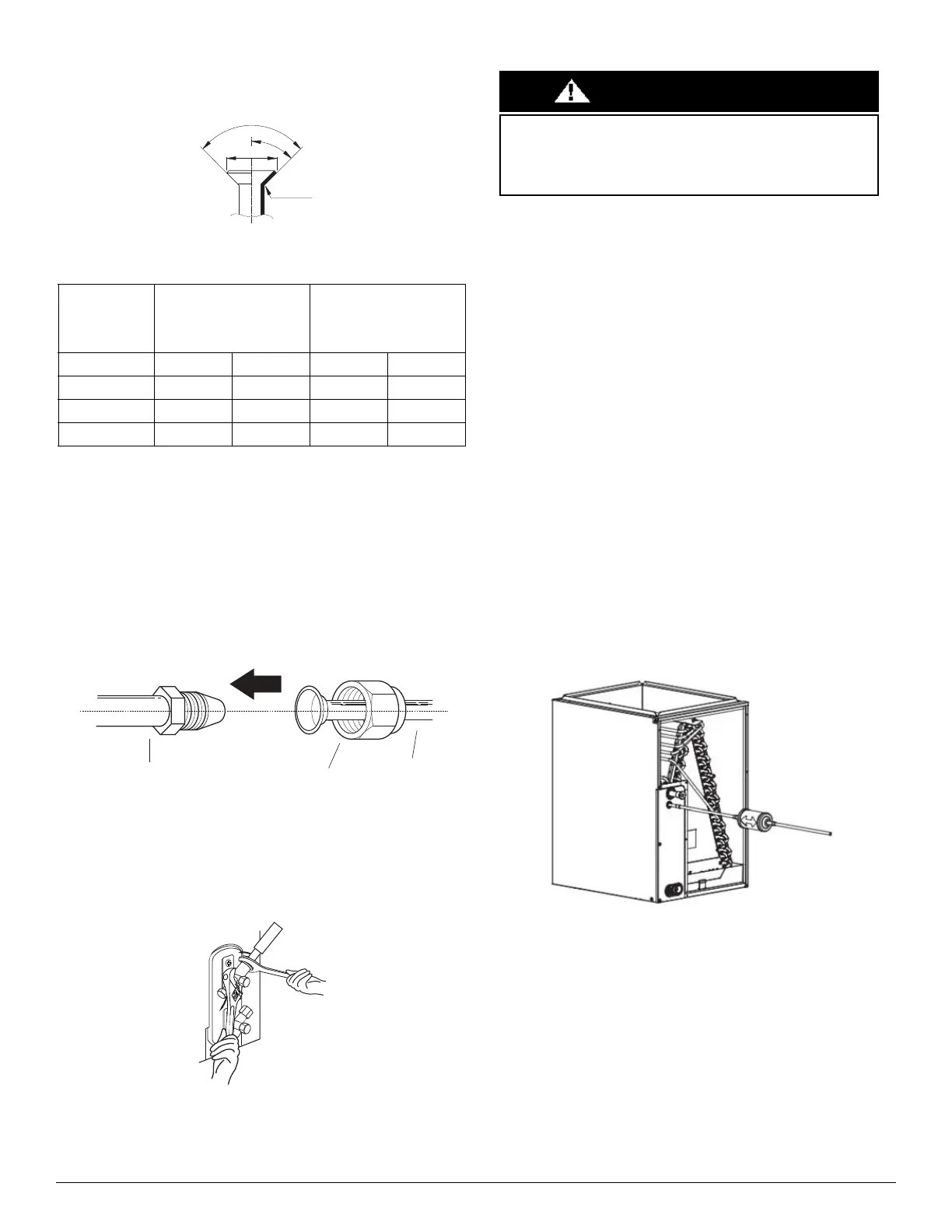

6. Connect the Pipes

Connect the copper pipes to the indoor unit first, then connect the

pipes to the outdoor unit. Connect the low-pressure pipe first, then

connect the high pressure pipe.

a. Align the center of the two pipes that you will connect.

Fig. 16 — Align the center of the two pipes

b. Tighten the flare nut as much as possible by hand.

c. Using a wrench, grip the nut on the unit tubing.

d. While firmly gripping the nut, use a torque wrench to tighten

the flare nut according to the torque values listed in Table 8.

Fig. 17 — Torque wrench with backup wrench

All tubing bends should be performed with a properly sized tubing bender

to prevent kinking or damaging the tubing.

e. After connecting the copper pipes to the indoor unit, wrap the

power cable, signal cable and the piping together with binding

tape.

NOTE: While bundling these items together, DO NOT intertwine or

cross the signal cable with any other wiring.

f. Thread this lineset through the wall and connect it to the

outdoor unit.

g. Insulate the suction line, including the outdoor unit valves.

NOTE: DO NOT open the service valves until pressure test is

complete.

7. Filter Drier (Heat Pump Drier ONLY)

Refer to Fig. 18 and install the drier as follows:

1.Cut a minimum 4" length of 3/8 tubing and assemble:

a. 3/8” adapter

b. short tubing

c. filter drier

d. lineset

2.Wrap filter drier with damp cloth.

3. Flow nitrogen.

4. Braze assembled components from step 1.

Fig. 18 — Filter Drier Components

The filter drier must be replaced whenever the refrigeration system is

exposed to the atmosphere.

Only use factory specified liquid-line filter driers with rated working

pressures less than 600 psig.

NOTE: Do not install a suction-line filter drier in liquid line.

BRASS

FLARE SIZES

RECOMMENDED

SEATING TORQUE FOR

BRASS FLARE NUTS

FLARE DIMENSIONS (A)

(INCH/MM)

In (mm) Ft-Lbs N-M Min Max

Ø3/8 (9.52) 23.6-28.8 32-39 0.52/13.2 0.53/13.5

Ø3/4 (19) 49.4-74.5 67-101 0.91/23.2 0.93/23.7

Ø7/8 (22) 62.7-81.1 85-110 1.04/26.4 1.06/26.9

Pipe

Indoor unit tubing

Flare nut

Wrap insulation around the piping. Direct contact with the bare

piping may result in burns or frostbite. Ensure the pipe is properly

connected. Over tightening may damage the bell mouth and under

tightening may lead to leakage.

CAUTION

Loading...

Loading...