16

TROUBLESHOOTING (CONTINUED)

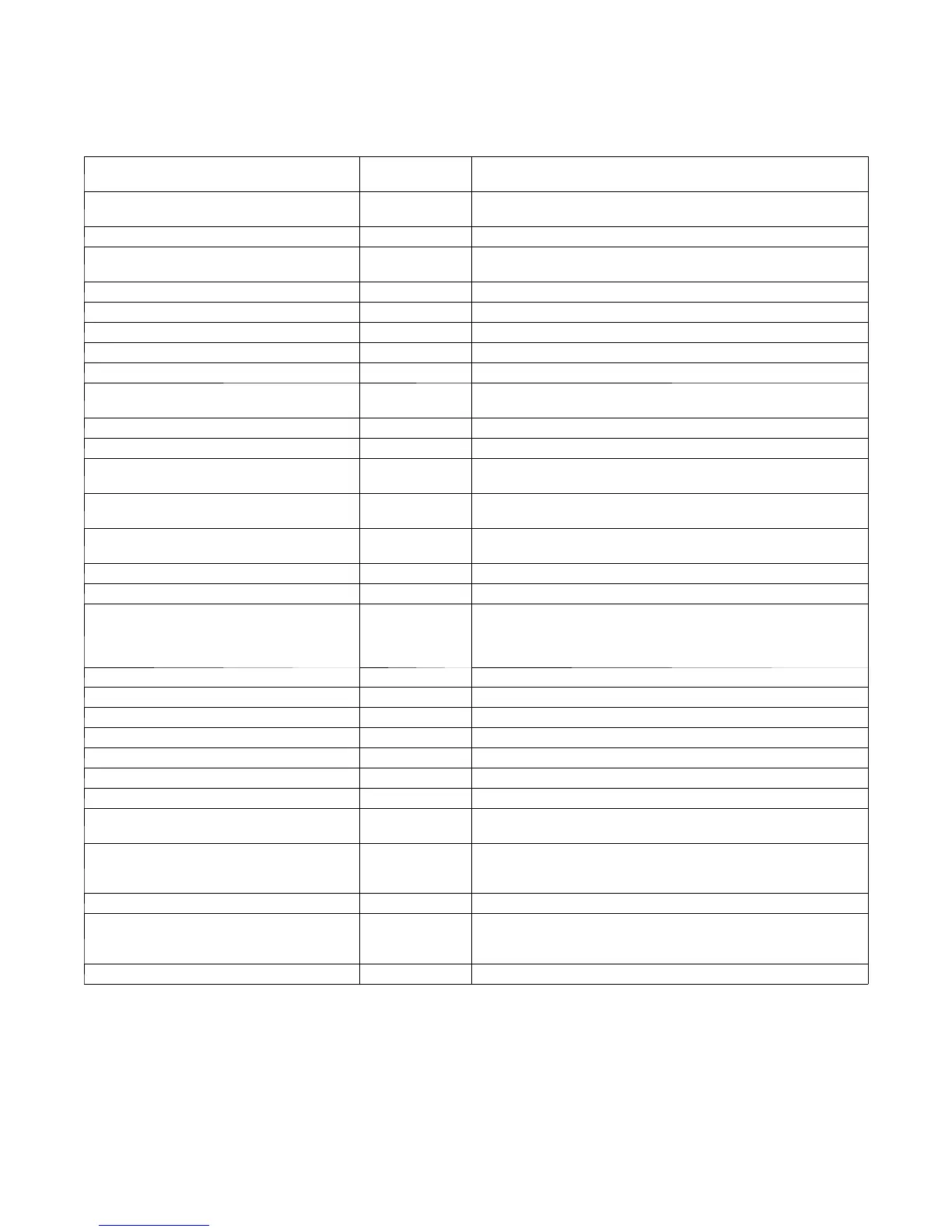

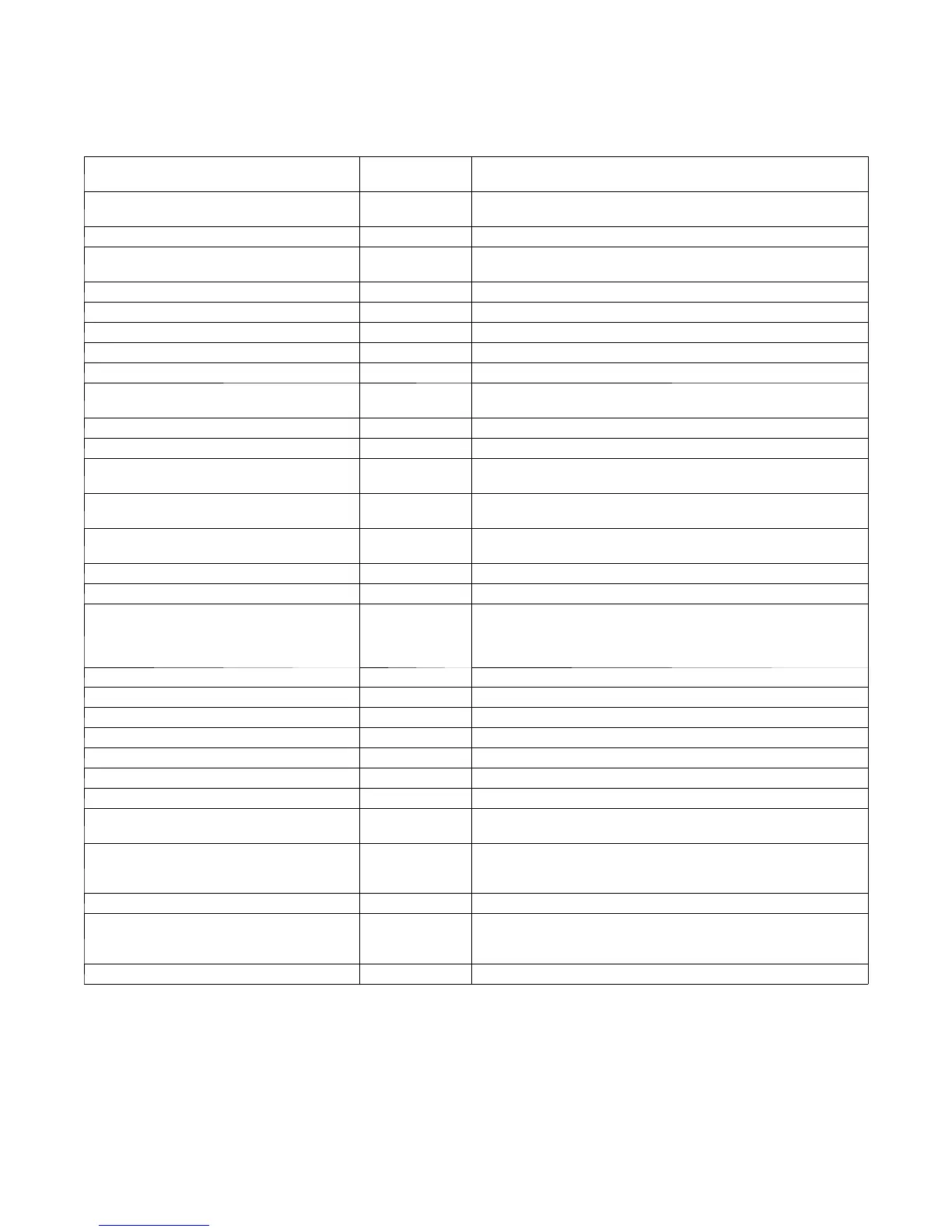

Diagnostic Codes

38/40GVC/Q 18k--24k, 230v

Malfunction

Error Code

on indoor unit

Repair Method/Cause

System high pressure protection E1

Poor heat exchange. Are the coils clogged or blocked? Is the ambi-

ent temperature out of system range?

Anti--- freeze Protection E2 Outdoor ambient temperature is too low

Discharge temperature sensor malfunction

(out of range)

E4 Measure the resistance value in the sensor

Low voltage protection E5 Check incoming power

Communication malfunction E6 Check wiring connection

System overload protection E8 Refer to Service Manual

Indoor board malfunction U8 Replace indoor main board

Indoor motor malfunction H6 Check motor mounting and wiring

Missing jumper from indoor board C5

No jumper on controller or installed improperly or damaged. Corres-

ponding circuit on main board has malfunction.

Return air temperature sensor malfunction F1 Measure the resistance value in the sensor

Indoor pipe temperature sensor malfunction F2 Measure the resistance value in the sensor

Outdoor ambient temperature sensor malfunc-

tion

F3 Measure the resistance value in the sensor

Condenser temperature sensor malfunction

(open or shorted)

F4 Measure the resistance value in the sensor

Discharge temperature sensor malfunction

(open or shorted)

F5 Measure the resistance value in the sensor

Overload limit, compressor speed reduction F6 Refer to Service Manual

Over current compressor speed reduction F8 System voltage is too low or system voltage is high

Compressor discharge temperature high,

compressor speed reduction

F9

Load is too great

Ambient temperature too high

Refrigerant is low

Electric expansion valve malfunction

Over voltage protection PH Check incoming power supply

Current detection malfunction U5 Replace outdoor main board

Compressor current protection P5 Refer to Service Manual. Check inverter board.

Defrosting H1 H1 signal normal operation

Compressor overload protection H3 Check overload wiring

System overload protection H4 Checked for dirty or blocked heat exchangers

IPM protection H5 IPM module over temperature, low voltage, silica grease problem

PFC (power factor correction) board protec-

tion

HC Refer to Service Manual

Compressor speed reduction H7

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

Ambient temperature cut off range H0 Refer to Service Manual (overload, high temperature, cutout)

Compressor start---up failure LC

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

Compressor phase detection error U1 Replace outdoor main board

Loading...

Loading...