12

Step 4 — Connect Piping —

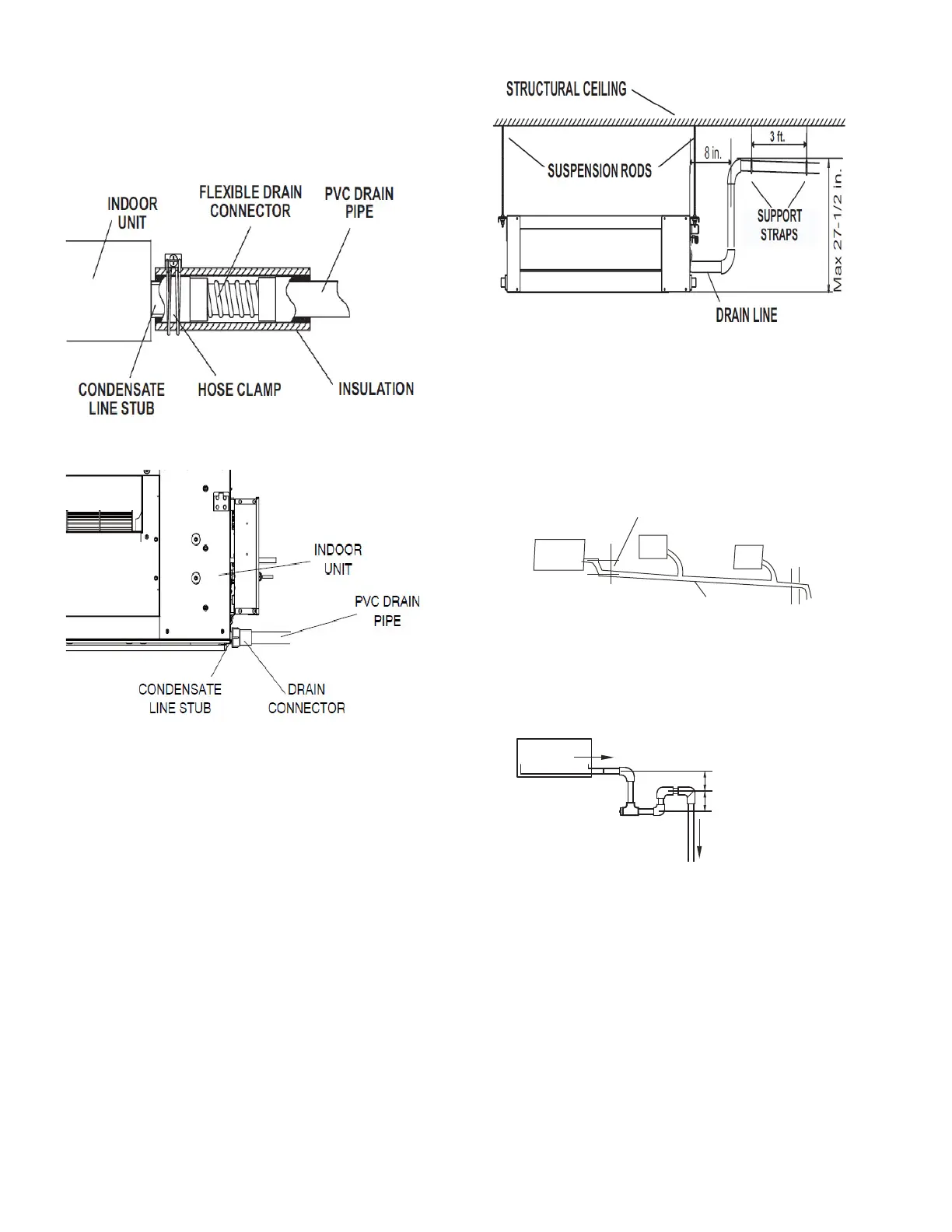

CONDENSATE PIPING — The unit is supplied with a one-

inch OD drain connection to connect copper or PVC drain

piping. See Fig. 14 and 15. Units of capacity size 2454 kBtu/h

come with a factory-installed condensate pump. The maximum

pump lift is 27-1/2 inches. Units of capacity size 7296 kBtu/h

do not have a factory-installed condensate pump.

Fig. 14 —Condensate Drain Connection (024 - 054)

Fig. 15 —Condensate Drain Connection (072 - 096)

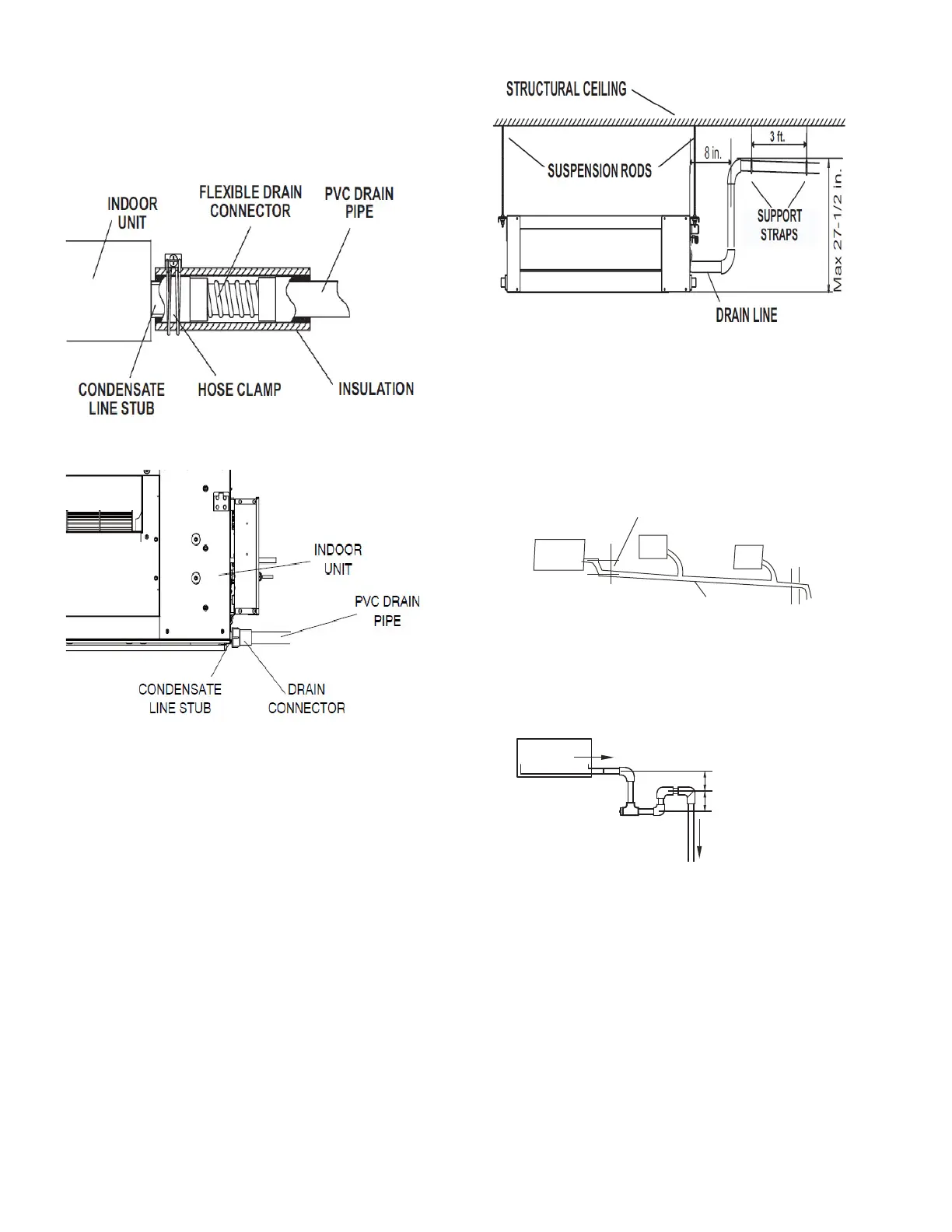

Follow these recommendations when installing condensate

piping:

• The highest point in the condensate piping should be as

close to the unit as possible. See Fig. 16.

• Condensate piping should slope downward in the

direction of condensate flow with a minimum gradient

of 1 inch per 100 inches. See Fig. 17.

Fig. 16 —Condensate Piping

• When multiple units are connected to a common

condensate drain, ensure that the drain is large enough to

accommodate the volume of condensate from all units. It

is also recommended to have an air vent in the

condensate piping to prevent air lock.

• Condensate piping must not be installed where it may be

exposed to freezing temperatures.

Fig. 17 —Using a Main Drain to Serve Multiple

Indoor Units

• Sizes 072-096 do not have a factory-installed condensate

pump and are “drawn through” fans that create suction.

Therefore, a condensate trap is required. See Fig. 18.

Fig. 18 —Trap at Piping End

• For gravity drain applications for sizes 024-054, CN18

can be disconnected to disable factory condensate pump.

• CN5 dry contract input can be used to interlock external

safeties such as a float switch.

Put as deep as possible

(about 10mm)

Downward slope

lower than 1/100

VP30

Indoor unit

H: 2''(50mm) or more.

+

+

Loading...

Loading...