44

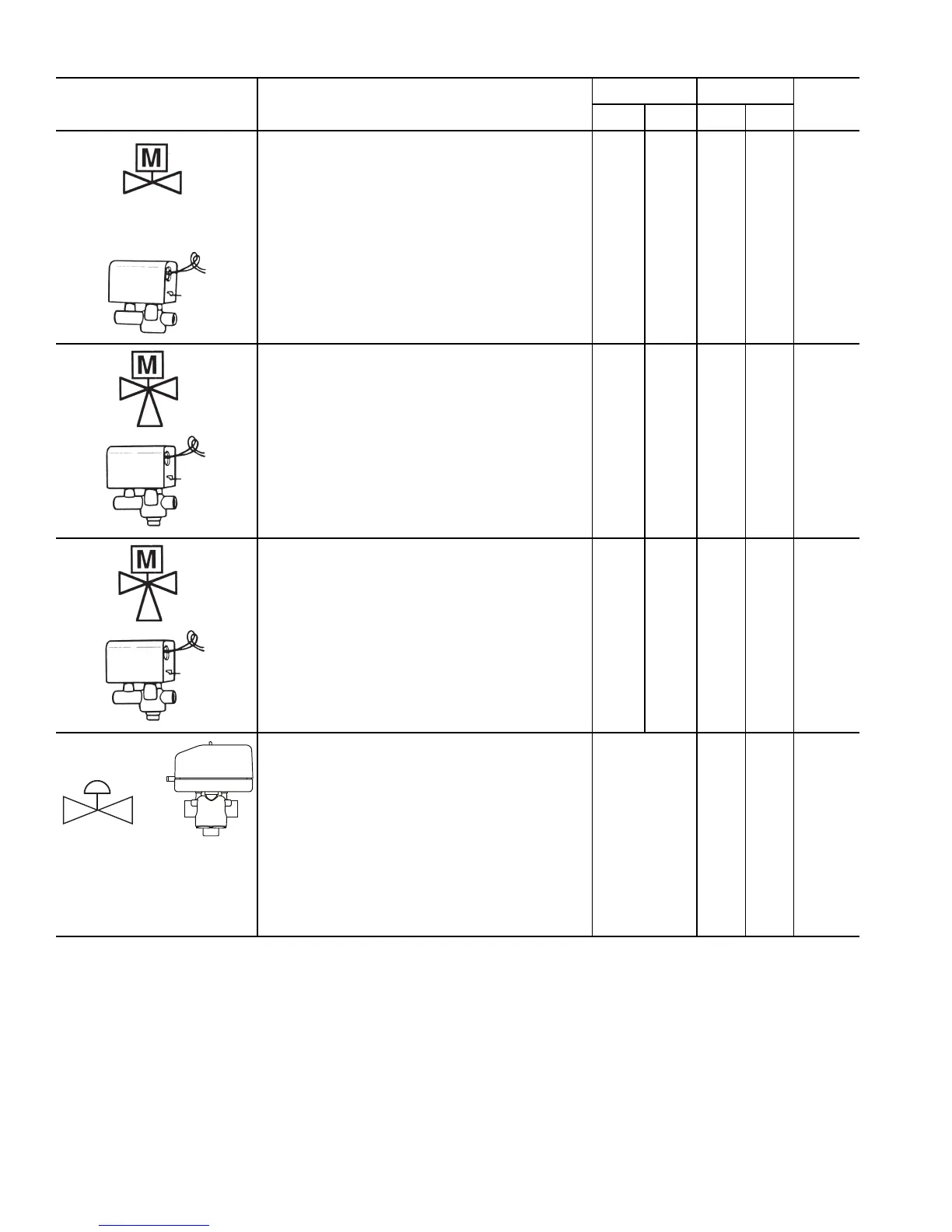

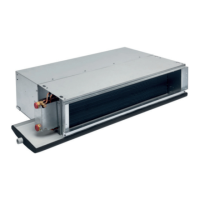

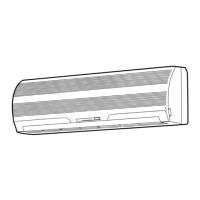

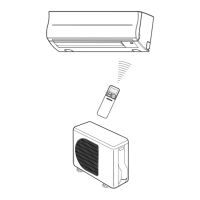

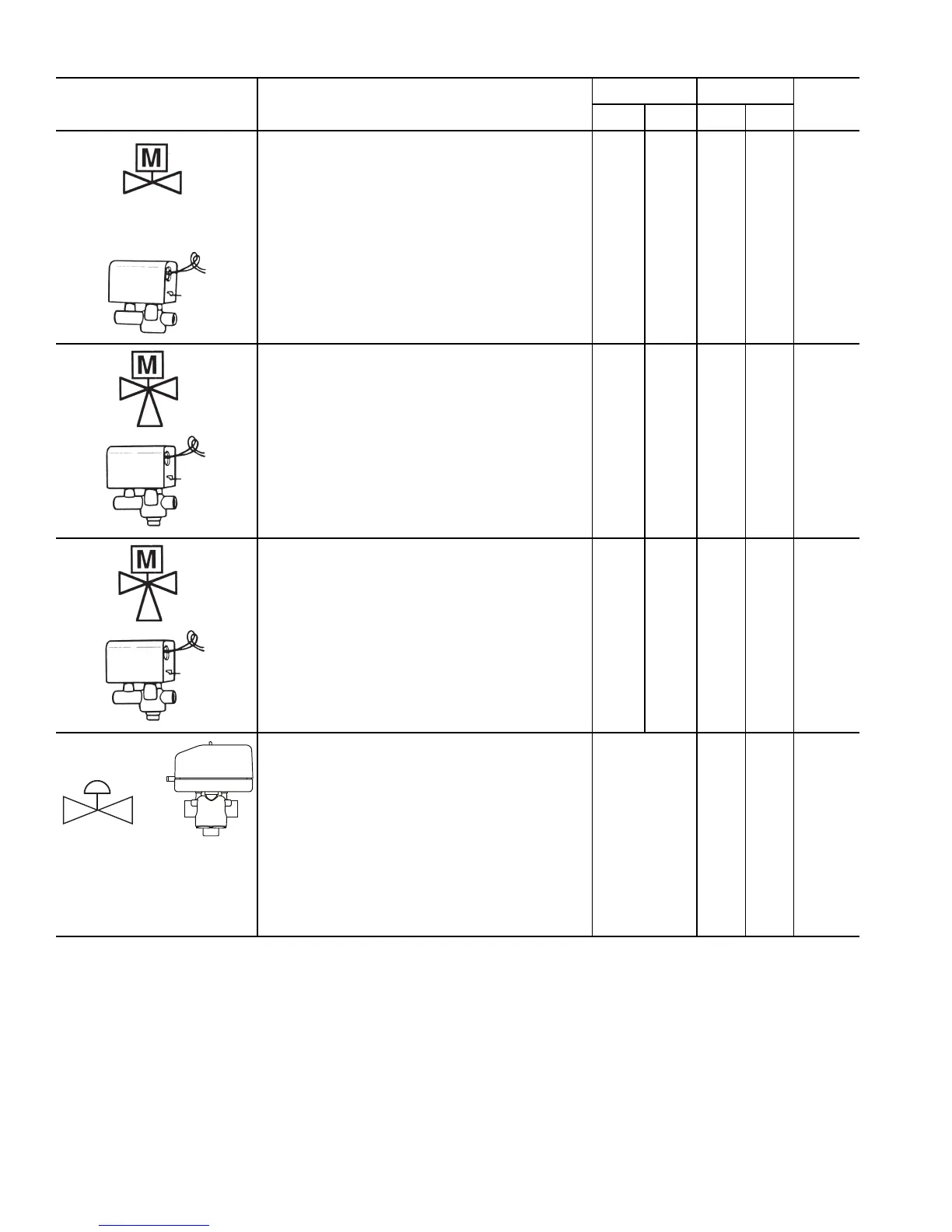

Table 5 — Piping Components (cont)

LEGEND *Check all system component pressure ratings (coils, values,

pumps, etc.) with manufacturer and any applicable local or national

piping codes prior to specifying system pressure rating.

SYMBOL/SKETCH DESCRIPTION

C

V

FACTOR RATING*

STEAM

USE

1

/

2

3

/

4

PSI F

2-WAY MOTORIZED VALVE (150 PSI close off dif-

ferential pressure): Electric 2-position flow control

valve (open/closed). Normally closed body with man-

ual override lever. Installed in supply line to unit.

Application — All standard control and valve pack-

ages are based upon normally closed valves (valve

electrically powered open and closed by spring

return when electric power removed). Manual over-

ride lever allows valve to be placed in the open posi-

tion for secondary (unit) flushing, constant water flow

prior to start-up, etc. Manual override is automati-

cally disengaged when valve is electrically activated.

Consult factory for normally open valve applica-

tions.

4.9 10.3 300 240 NO

3-WAY MOTORIZED VALVE (25 PSI close off dif-

ferential pressure): Electric 2-position flow control

valve (closed to coil/open to bypass or open to coil/

closed to bypass). Normally closed with manual

override lever. Installed in supply line to unit.

Application — Same comments as 2-way motorized

valve except with manual override lever engaged the

valve is open to both ports and water flow will take

the path of least resistance through the valve pack-

age (not necessarily 100% through the coil).

4.0 4.0 300 200 N/A

3-WAY MOTORIZED VALVE (150 PSI close off dif-

ferential pressure): Electric 2-position flow control

valve (closed to coil/open to bypass or open to coil/

closed to bypass). Normally closed with manual

override lever. Installed in supply line to unit.

Application — Same comments as 2-way motorized

valve except with manual override lever engaged the

valve is open to both ports and water flow will take

the path of least resistance through the valve pack-

age (not necessarily 100% through the coil).

4.9 4.9 300 240 N/A

MODULATING VALVE (Optional)

(Non-Spring Return, Floating Point Actuator):

Modulating valves are designed to control the flow in

the circuit by making incremental adjustments to the

flow path within the valve.

Application — To control fluid flow in fan coil units.

On the 42DD commercial fan coil models, the factory

provided modulating valve has application restric-

tions. In these models, the valve packages are

located in the airstream, downstream of the coil. Due

to the ambient temperature limitations of the modu-

lating valves, the valves can only be used in the units

listed above with 2-pipe cooling only systems.

4.0 300 200

N/A

C

v

— Coefficient of Velocity

DX — Direct Expansion

ETO — Engineering to Order

Loading...

Loading...