FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

25

present but no output, replace PCB. If output is present, replace

relay.

Heater Will Not Turn Off

1. Check low-voltage wiring for miswire.

2. Check for shorted elements to ground.

3. Replace sequencer/relays. They may be stuck closed.

Nuisance Trips

1. Check for low airflow due to dirty filters, blocked registers, or

undersized duct.

2. Check blower motor and wheel for proper operation. Excessive

current draw of motor will cause internal overload to trip.

3. The fan speed may be low.

FFM, FMA

This section describes EHK2 series electric heaters by examining

functional operation of this heater.

Service can be completed with heater in place. Shut off power before

servicing.

Description of Electric Heater Components

Limit Switch

The limit switch is a temperature sensitive control that’s function is to

prevent system from overheating in abnormal conditions. The

temperature settings often vary from heater to heater due to variations in

airflow patterns and element radiant heat conditions.

The devices are sized to remain on-line under heat pump conditions

(115° F air off coil) and minimum CFM, but trip to prevent outlet air

conditions above 200° F or excessive component or duct temperatures.

The device itself consists of a bimetallic disc, which when overheated

“snaps through” to open a normally closed high-voltage, high-current

switch. When system temperatures cool sufficiently, the switch will

automatically reset to its closed position. Normal failure mode for this

switch is open.

If a limit switch has been determined to be defective, NEVER BYPASS

THE LIMIT SWITCH. When replacing limit switch, ensure that it is

replaced with a limit switch of identical opening temperature and closing

differential. Limits switches are typically color-coded to identify their

range.

Sequencer

Early production EHK2 heaters have sequences controlling the heater

elements. The sequencer is essentially a thermally-activated time-delay

relay normally activated by low-voltage control signals from thermostat.

The typical sequencer is a 1- or 2-pole normally open device which

energizes within 30 to 70 seconds after application of control signal and

de-energizes 60 to 90 seconds after control signal is removed.

In simplistic terms, the sequencers which we use are nothing more than

normally open limit switches which sit on top of a small resistive heater.

When voltage is applied to this heater, a positive temperature coefficient

resistor (PTC), heat is supplied to a bimetallic disc which “snaps

through” and closes switch.

The time required for PTC to heat to a sufficient point controls ON

timing of device. The time required for disc to cool down when power is

removed controls OFF time of device. The PTC can be varied to provide

varied timing. Typically a short ON equates to a long OFF.

Because this is a thermally-activated device, ambient conditions affect

the ON/OFF cycle. Higher ambient temperature means shorter ON times

and longer OFF times.

Application of these devices is such that the first switch ON not only

turns on first heater element, but also ensures that indoor fan is

energized, because first ON is last OFF. This ensures fan remains ON

until the last heater de-energizes. The Time Delay Printed Circuit Board

(PCB) is a logic controlled time delay activated by low-voltage control

signal (G) from thermostat. The PCB includes a normally open relay

which closes to energize the blower motor when the G terminal is

energized. Then when the G terminal is de-energized the relay

energizing the blower motor remains closed for 90 – 100 seconds before

opening.

Relays

Later production EHK2 heaters have relays controlling the heater

elements instead of sequencers. A small rectifier PCB is mounted to

each relay which converts the incoming 24VAC control signal to DC.

In addition to the rectifier circuit, the second and third stage relays

contain a time-on delay circuit of five seconds for second stage, and

eight seconds for third stage. When the control signal is removed from

the relays, all relays will open with no time-off delay.

Leak Dissipation System

Operation (Models with R-454B Refrigerant)

When no leak is detected, G, Y, and W pass through the dissipation board

and operate normally. In this state, the Dissipation Board Status LED

remains solid yellow. When the A2L Detection Sensor reaches a

threshold of detected R-454B refrigerant, the Status LED flashes one

time and the dissipation board enters dissipation mode. While the

detected refrigerant is over the threshold, the Status LED will continue to

flash a Fault Code of 1. After the level is lower than the threshold, the

Status LED flashes a code of 3 as the dissipation board completes its

dissipation actions. These actions include de-energizing Y and W and

energizing G for 15 minutes. After the 15 minutes if the refrigerant

detected is below the threshold, there is a 5 minute delay before

returning to normal operation. If the refrigerant detected is above the

threshold, G continues to be energized until refrigerant is below the

threshold. At that point the 5-minute delay begins.

After dissipation is complete, the unit returns to normal operation with

the Status LED being solid.

System Self-Test

Power on the unit and verify proper functioning of equipment. The

yellow LED on the dissipation board should be steady. If flash codes are

present, see (Troubleshooting on p26).

NOTE: Operation of the Test Mode is only possible if no faults exist on

the dissipation board.

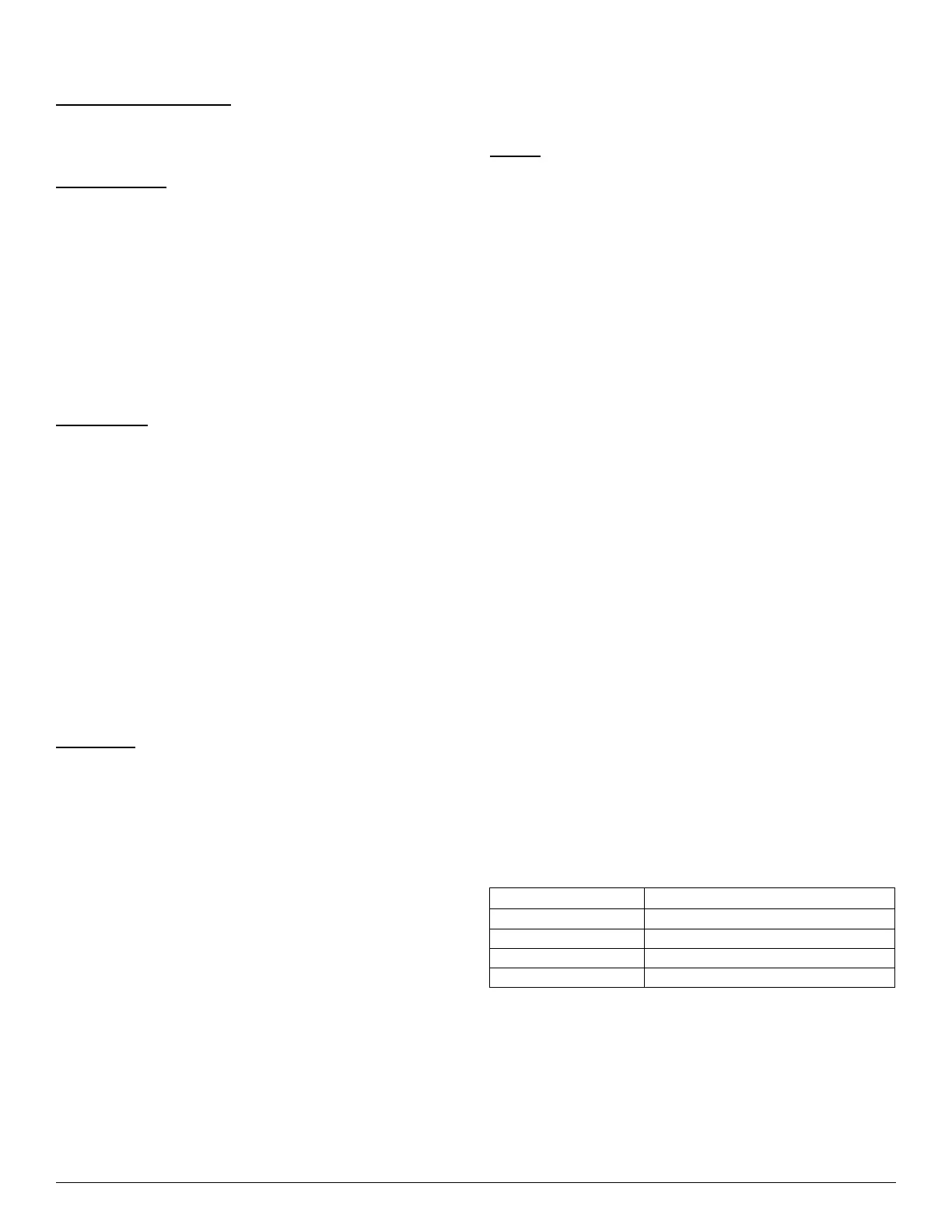

IMPORTANT: Press the Test button for roughly ONE SECOND to

enter Test Mode. Pressing the Test button for a longer periods enables

different functions (Table 13).

Press the Test button on the dissipation system control board to ensure

proper dissipation system operation under each test condition listed

below. After pressing the Test button, system will enter Dissipation

Mode for 60 seconds to help verify correct operation.

Ensure that the fan coil is able to meet the minimum required dissipation

mode airflows. These required minimum airflow rates during

Dissipation Mode are listed in Table 15. They are based on the total

system refrigerant charge quantity.

Table 13 – Dissipation Board Test Button Functions

Hold Button Time (sec) Function

1 - 4 Dissipation Mode for 60 seconds

5 - 29 Display flash code history

30+ Flash code 6

3 rapid presses Clear flash code history

Loading...

Loading...