FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

4

blows when there is a high current draw on transformer, high

voltage applied to low-voltage circuit, or a direct secondary short.

When there is a high current draw on transformer, it is most likely

because transformer has been shorted or system is trying to draw

more VA than transformer rating allows. When fuse blows because

of high voltage, the system has mixed high- and low-voltage

signals.

(1.) Check wiring of sequencers/relays as shown in Fig. 1 and

Fig. 2. Be sure transformer is not shorting out because

thermostat wires are miswired.

(1.) Check wiring of relays as shown in Fig. 1 and Fig. 2. Be

sure low-voltage and high-voltage wiring is correct.

(1.) Check VA draw on transformer. If VA draw is more than VA

rating of transformer, fuse will blow. If this is the case,

replace transformer with one that has a higher VA rating and

meets system specifications.

If Fan Runs Continuously:

(1.) If PCB has no low-voltage power, check blue and black fan

leads. These may be switched at sequencer/relay.

(1.) If PCB has low-voltage power, check fan relay to see if it is

opening and closing. It may be stuck in the normally closed

position due to debris in relay.

Transformer Failure:

Check 208V and 230V transformer connections. They may be

miswired.

A03010

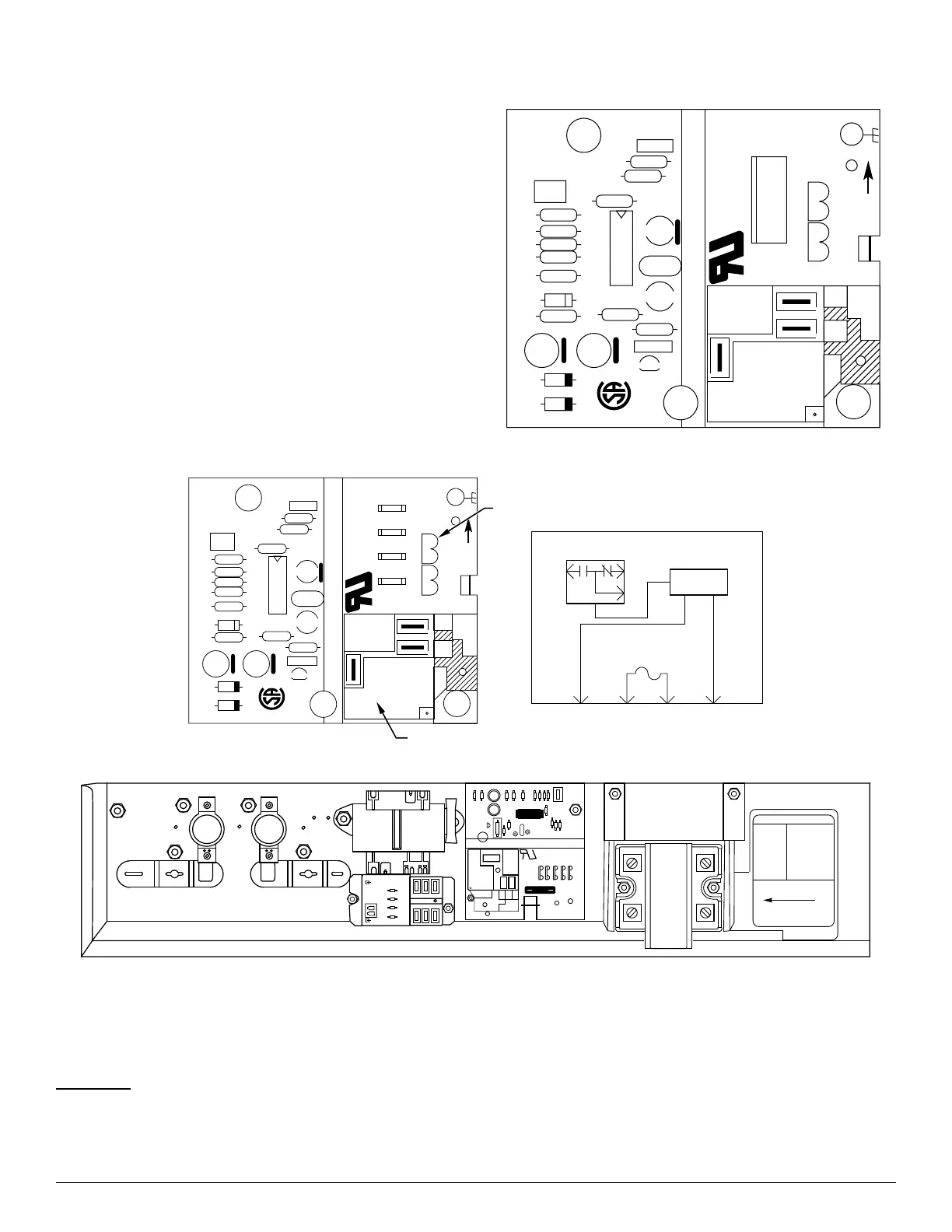

Fig. 1 – Fan Coil Printed Circuit Board (HK61EA006)

A97020

Fig. 2 – Fan Coil Printed Circuit Board (CES013003-00, 01 / HK61EA002)

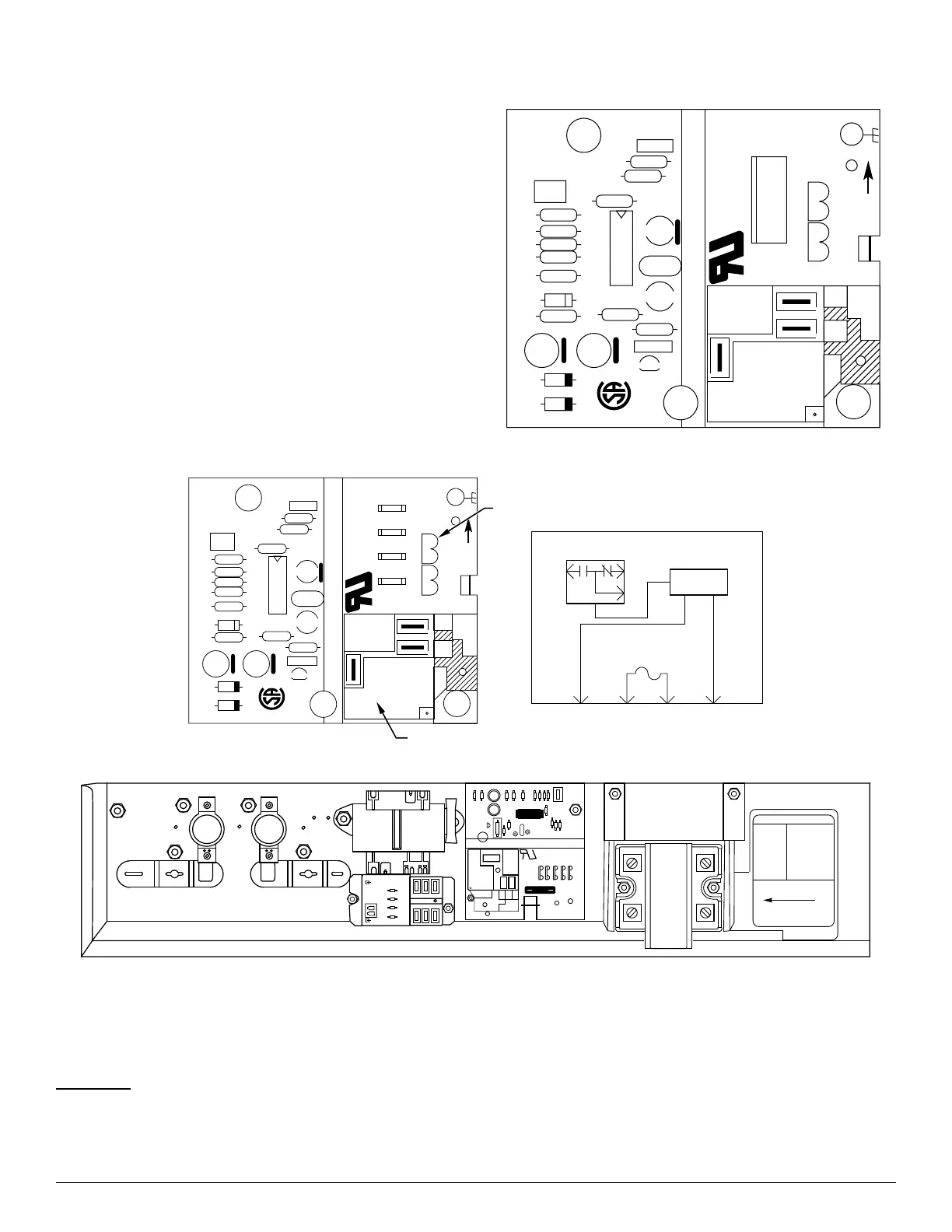

A13032

Fig. 3 – Electric Heater Control Box

FB4C, FJ4, FX4D, F54, PF4, FF1E, and FZ (odd

sizes)

Fan Motor

The multi-speed ECM motor used with this product contains two parts:

the control module and the motor winding section. Do not assume the

motor or module is defective if it will not start. Go through the steps

described below before replacing control module or entire motor. The

control module is available as a replacement part.

1. It is normal for the motor to rock back and forth on startup. Do not

replace the motor if this is the only problem identified.

(1.) If the motor is not running:

• Check for proper high voltage and ground at the L,G, and

N connections at the motor. Correct any voltage issue

before proceeding to the next step.

®

®

CPC-E

94V-0

LR40061

HSCI

5 AMP

C

T

G

R

SPT

K1

U1

R7

R9

R10

C8

C7

R2

R3

C3

R6

R11

C4

C6

C5

R8

R5

R4

Q1

C1C2

F1

JW1

R1

Z1

D2

D1

NO

NC

FAN

RELAY

C

C

LOW

VOLTAGE

FUSE

FAN RELAY

FUSE

PCB BLOCK WIRING

TIME

DELAY

NO

GRTC

NC

SPT

®

®

1005-83-161ACPC-E

94V-0

1005-161

LR40061

CESO130003-01

HSCI

5 AMP

TRG C

C

T

G

R

SPT

K1

U1

R7

R9

R10

C8

C7

R2

R3

C3

R6

R11

C4

C6

C5

R8

R5

R4

Q1

C1C2

F1

JW1

R1

Z1

D2

D1

NO

NC

FAN

RELAY

312753

T-O-D 60TX11

HH19ZA945

C9725

L145-55F

312753

T-O-D 60TX11

HH19ZA945

C9725

L145-55F

SPT

FAN

RELAY

NO

NC

5

PULL TO OPEN

WARNING

ELECTRIC SHOCK

HAZARD

DISCONNECT

REMOTE POWER

SUPPLY BEFORE

OPENING PANEL.

322861-101 REV. A

FF1E CONTROL BOX

Loading...

Loading...