Specifications are subject to change without notice.

20

441 01 3400 02

NOTE: The J--Box cover need not be removed from the J--Box

in order to move the J-- Box. Do NOT remove green ground

screw inside J--Box.

2. Cut wire tie on loop in furnace wires attached to J--box.

3. Move J-- Box to desired location.

4. Fasten J--Box to casing with two screws removed in Step 1.

5. Route J--Box wires within furnace away from sharp edges,

rotating parts and hot surfaces.

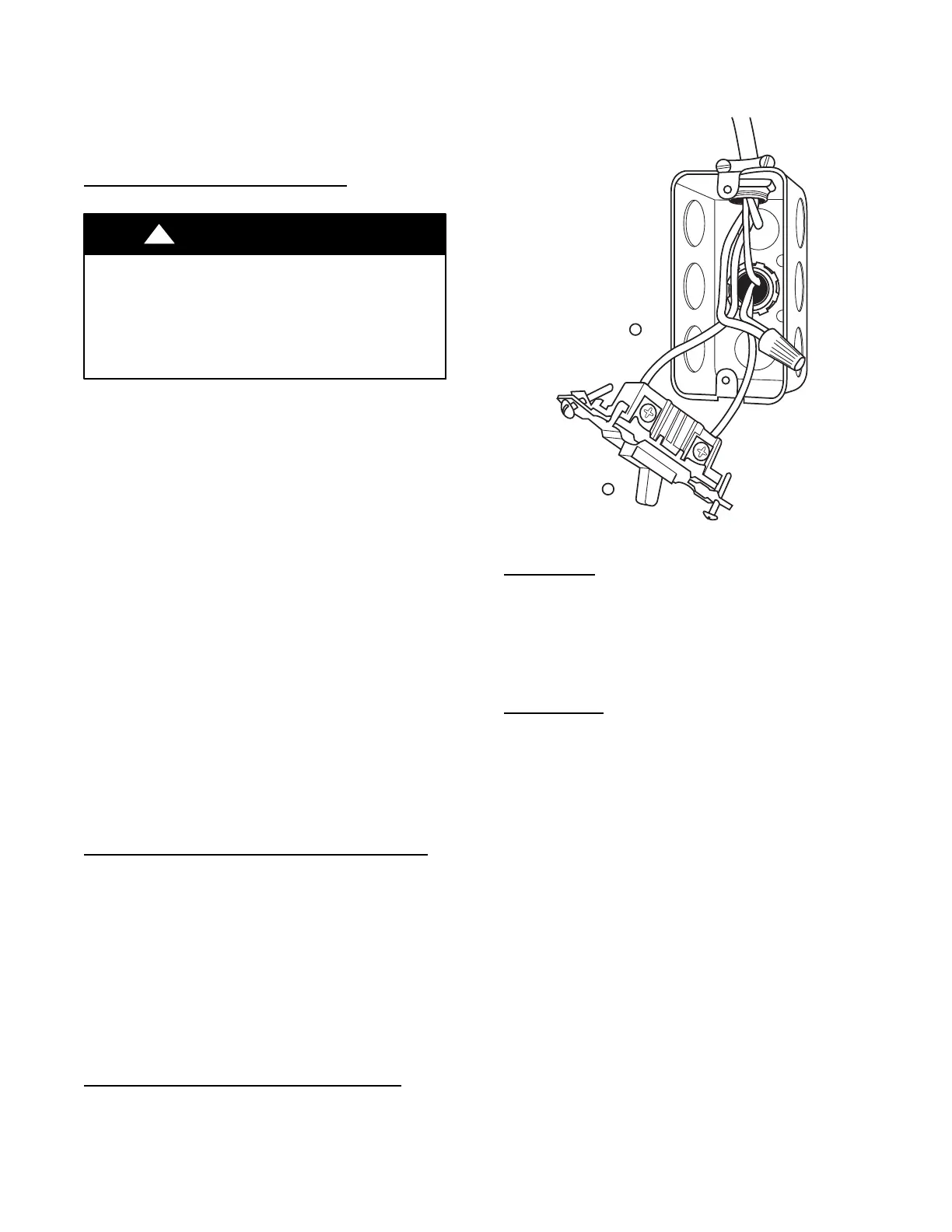

ELECTRICAL CONNECTION TO J--BOX

Electrical Box on Furnace Casing Side

FIRE OR ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

If field -- supplied manual disconnect switch is to be mounted

on furnace casing side, select a location where a drill or

fastener cannot damage electrical or gas components.

!

WARNING

1. Select and remove a hole knockout in the casing where the

electrical box is to be installed.

NOTE: Check that duct on side of furnace will not interfere with

installed electrical box.

2. Remove the desired electrical box hole knockout and posi-

tion the hole in the electrical box over the hole in the fur-

nace casing.

3. Fasten the electrical box to casing by driving two field

supplied screws from inside electrical box into casing

steel.

4. Remove and save two screws holding J--Box.

5. Pull furnace power wires out of 1/2 -- in. (12 mm) diameter

hole in J--Box. Do not loosen wires from strain-- relief

wire--tie on outside of J--Box.

6. Route furnace power wires through holes in casing and

electrical box and into electrical box.

7. Pull field power wires into electrical box.

8. Remove cover from furnace J-- Box.

9. Route field ground wire through holes in electrical box

and casing, and into furnace J-- Box.

10. Reattach furnace J--Box to furnace casing with screws re-

movedinStep4.

11. Secure field ground wire to J--Box green ground screw.

12. Complete electrical box wiring and installation. Connect

line voltage leads as shown in Fig. 25. Use best practices

(NEC in U.S. for wire bushings, strain relief, etc.)

13. Reinstall cover to J -- Box. Do not pinch wires between

cover and bracket.

POWER CORD INSTALLATION IN FURNACE

J--BOX

NOTE: Power cords must be able to handle the electrical

requirements listed in Table 7. Refer to power cord

manufacturer’s listings.

1. Remove cover from J -- Box.

2. Route listed power cord through 7/8--in. (22 mm) diameter

hole in J--Box.

3. Secure power cord to J--Box bracket with a strain relief

bushing or a connector approved for the type of cord used.

4. Secure field ground wire to green ground screw on J--Box

bracket.

5. Connect line voltage leads as shown in Fig. 25.

6. Reinstall cover to J -- Box. Do not pinch wires between

cover and bracket.

BX CABLE INSTALLATION IN FURNACE

J--BOX

1. Remove cover from J -- Box.

2. Route BX cable into 7/8-- inch diameter hole in J--Box.

3. Secure BX cable to J--Box bracket with connectors ap-

proved for the type of cable used.

4. Secure field ground wire to green ground screw on J--Box

bracket.

5. Connect line voltage leads as shown in Fig. 25.

6. Reinstall cover to J -- Box. Do not pinch wires between

cover and bracket.

A10141

Fig. 23 -- Field--Supplied Electrical Box on Furnace Casing

24--V

WIRING

Ma ke field 24--v connec t ions at the 24--v t erminal st ri p. (See Fig.

25.) Conne ct ter m ina l Y as shown in Fi g. 24 for pr oper c ooli ng

opera tion. Use only AWG No. 18, color--coded, copper ther m ostat

wir e .

The 24--v circuit contains an automotive--type, 3--amp. fuse located

on the control. Any direct shorts during installation, service, or

maintenance could cause this fuse to blow . If fuse replacement is

requi r ed, use ONLY a 3--amp. fuse of i dentic al si ze.

ACCESSORIES

1. Electronic Air Cleaner (EAC)

Connect an accessory Electronic Air Cleaner (if used) using

1/4--in female quick connect terminals to the two male 1/4--in

quick--connect te rmi nals on the contr ol board marke d

EAC--1 and EAC--2. The terminals are rated for 115 VAC,

1.0 amps maxi m um and ar e energiz ed during blowe r motor

opera t ion. (See Fig. 24.)

2. Humidifier (HUM)

S a. 24VAC HUM: Connect an accessory 24 VAC, 0.5

amp maximum humidifier (if used) to the 1/4-- in male

quick--connect 24VAC HUM terminal and C screw

terminal on the control board thermostat strip. The

24VAC HUM terminal is energized when there is a call

for heat (W) and the pressure switch (PRS) closes. (See

Fig. 24 and 48).

S b. HUM: Connect an accessory 115VAC (EAC and

HUM are 1 amp maximum combined) humidifier (if

used) to the ¼--inch male quick connect HUM terminal

and EAC--2 ¼--inch quick connect. The HUM terminal

is energized when the inducer motor is energized

(IDR). (See Fig. 24 and 48).

NOTE: A field--supplied, 115--v controlled relay connected to

EAC terminals may be added if humidifier operation is desired

during blower operation.

NOTE: DO NOT connect furnace control 24VAC HUM

terminal to H (humidifier) terminal on humidity sensing

thermostat, or similar device. See humidity sensing thermostat,

thermostat, or controller manufacturer’s instructions for proper

connection.

Loading...

Loading...