1-1

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

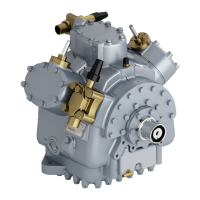

This operation and service manual covers the Carrier

Transicold Model 05G compressors. These compressors

are designed for refrigeration (trailer) or air conditioning

(bus & rail) applications. (See Figure 1-1) The following

table list the special tools for the 05G compressors.

PART NO.

SPECIAL TOOLS

07-00219 Wrench, Compressor Sight Glass

07-00223 Pliers, Compressor Unloader Ring

07-00240-01

Wrench, Spanner

(for Housing Mounted Clutch)

07-00241

Rotor Installation Tool

(for Housing Mounted Clutch)

07-00242-01

Bearing Retaining Nut Socket

(3.5

""

)

(Housing Mounted Clutch)

07-00242-02

Bearing Retaining Nut Socket

(3

""

)

(for Housing Mounted Clutch)

07-00260-00 Acid Test Kit

07-00265-01 To ta lt es t Ki t ( Pa ck ag e of 1)

07-00266-00 Replacement Tubes for Totaltest Kit

58-00869-00

Filter, Felt (Suction Sock for

System Clean Up)

1.2 GENERAL DESCRIPTION

The Model 05G compressors are of the open-drive

reciprocating type. A crankshaft, connecting rods,

pistons, and reed type valves accomplish vapor

compression. Compressor wear is minimized by splash

lubrication and by force feed lubrication. There are three

types of oil pumps (Vane, Gear and Low Profile Gear)

driven directly from the end of the compressor

crankshaft. (See Figure 1-3)

CAUTION

The gear oil pump must be set to rotate in the

same direction as the crankshaft. (Refer to

section 3.4)

The tapered end of the crankshaft, which extends

outside the crankcase, is adaptable to a variety of direct

drive or belt---driven clutch mechanisms. A mechanical

seal prevents refrigerant l eakage where the rotating shaft

passes through the crankcase.

The compressor is equipped with flanges for

connecting suction and discharge service valves.

Connections are also provided for pressure gauges and

safety cutout switches. Sight glasses installed on both

sides of the crankcase, provides a means for checking oil

level in the compressor crankcase. A drain plug facilitates

draining of oil from the crankcase and an oil fill plug

enables addition of oil when necessary. A bottom plate

provides access through the bottom of the crankcase for

maintenance.

WARNING

Do not operate compressor unless suction and

discharge service valves are o pen.

Capacity of the Model 05G compressor is

determined by piston displacement and clearance,

suction and discharge valve size, compressor speed,

suction and discharge pressure, type of refrigerant, and

unloader valves.

1.3 COMPRESSOR REFERENCE DATA

Model

05G---37CFM 05G---41CFM

Displacement 37CFM 41CFM

No. Cylinders 6

Bore 50.8 mm (2.00 in)

Stroke

49.2 mm

(1.937 in)

54.36 mm

(2.14 in)

Weight 62 kg (137 lbs)

SPEED (RPM) FOR OIL PUMP

Vane 900 to 2200

Gear 500 to 2200

Low Profile Gear 500 to 2200

NOTE

The oils below are suitable for use with

evaporator temperatures above ---4 0˚F

( --- 4 0 ˚C).

Approved Oil for REFRIGERATION USE

(TRAILER)

Refrigerant Oil

R-12, R-22, R-500

or R-502

Zerol: 150 Synthetic

P/N 07-00274

Castrol Icematic: SW-68C

R-404A

Mobil Arctic: EAL 68

ICI: Emkarate RL68H

Approved Oil for AIR CONDITIONING USE

(BUS AND RAIL)

Refrigerant Oil

Calumet Refining: R030

R-12 or R-22

Tex ac o: WF6 8

Witco: 4GS Suniso

Castrol Icematic: SW-68C

R-134a

Mobil Arctic: EAL 68

ICI: Emkarate RL68H

Revised 10/96

Loading...

Loading...