30

AFS

Grain Moisture and Weight Calibration (cont.)

• If moisture readings are consistently very low, the auger may

be operating constantly, preventing grain contact with the

fin. (Likely to occur only in lower yield crop where the bypass

auger removes grain from the bypass as quickly as

it enters).

• Your Case IH dealer should be consulted to correct

the condition

• If moisture readings are consistent, but at a value more

likely to be representative of actual grain moisture content,

the auger may not be operating

• The sensor is merely providing a moisture reading of a static

sample that is in the bypass housing

The bypass auger is controlled by a proximity switch that

cycles the auger as required, to assure the sensor fin is always

in contact with grain.

• The auger should operate for 30 seconds after the separator

is disengaged, to clean grain from the bypass. Auger

operation can be checked by visually watching the end of

the auger shaft during this 30 second period, to see if the

shaft is turning.

• If not, check to assure the moisture sensor bypass auger

use is not blown. If the fuse is not at fault, contact your

Case IH dealer for assistance.

Operators must also remember that adjustment or replacement of

any component that affects calibration requires re-calibration.

• Memory management features of AFS allows operators to

apply calibration values to specific loads, or beginning at a

specific time during harvest, such as the time when

component replacement occurred.

• Refer to the Operator’s Manual after re-calibration to use the

correct Utility menu to apply calibration to the correct

harvest data.

To record harvest data, four criteria must be met.

• A memory card must be inserted in the top slot of the

display before turning the power ON. The card should have

only ONE *.yld file or ONE *.cnh folder. Use Windows

Explorer to confirm.

• The clean grain elevator must be running between 250 and

599 RPM

• Ground speed must be registered

• The header must be lowered below the header cut “stop

height” position

When data is being recorded, the “REC” indicator on the

display will be darkened.

In understanding the calibration process, the operator realizes

the importance of maintaining an accurate record of the

calibration load weight and moisture test results, as well as

load identification.

• Identification is necessary to enter a load name into AFS,

as well as on scale tickets. The operator should anticipate

the need for load names, and can actually enter load names

prior to harvest.

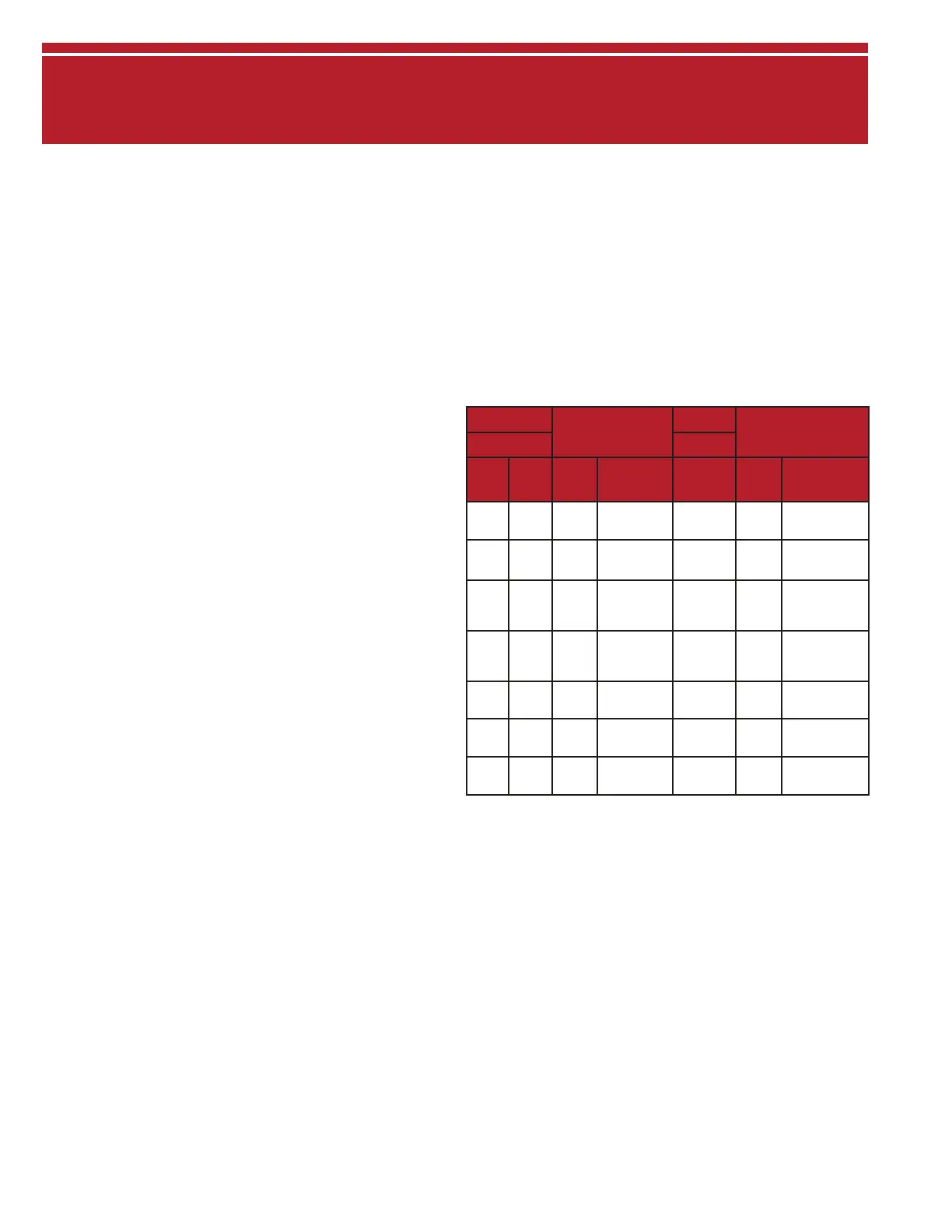

See the calibration record table included in the

AFS Operator’s Manual or

(see table 30.1).

Crop Type: Date:

Combine: Operator

Field Load

Flow

Bu/Hr

Estimated

Weight

Actual

Weight

%

Error

Include?

(Y/N)

1

Cal

1Hi

2

Cal

2Hi

3

Cal

1

Med

4

Cal

2

Med

5

Cal

1Lo

6

Cal

2Lo

7

Table 30.1

Loading...

Loading...