GENERAL INFORMATION

1 - 11

CASE TRAINING CENTER

AUGUST 2000

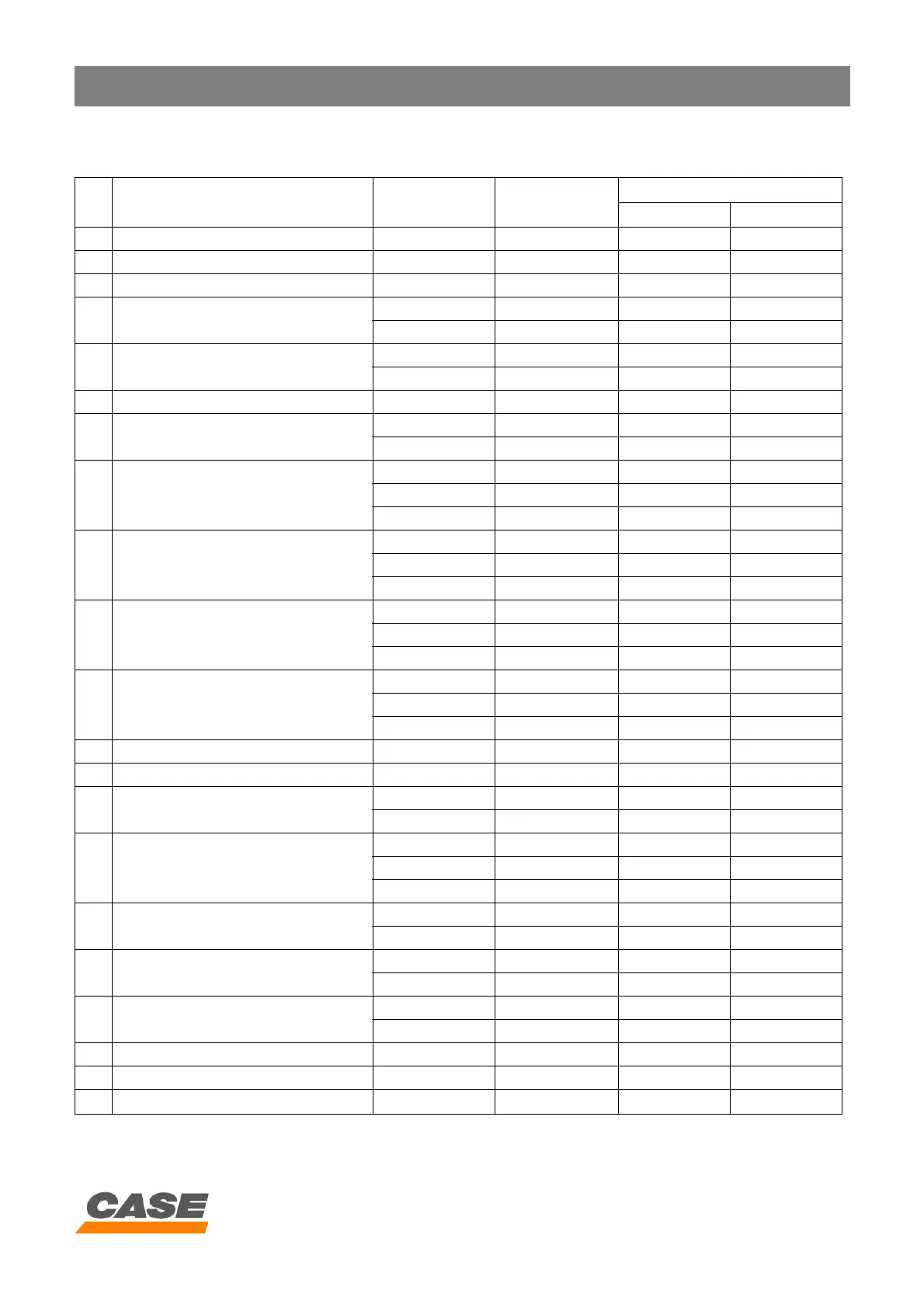

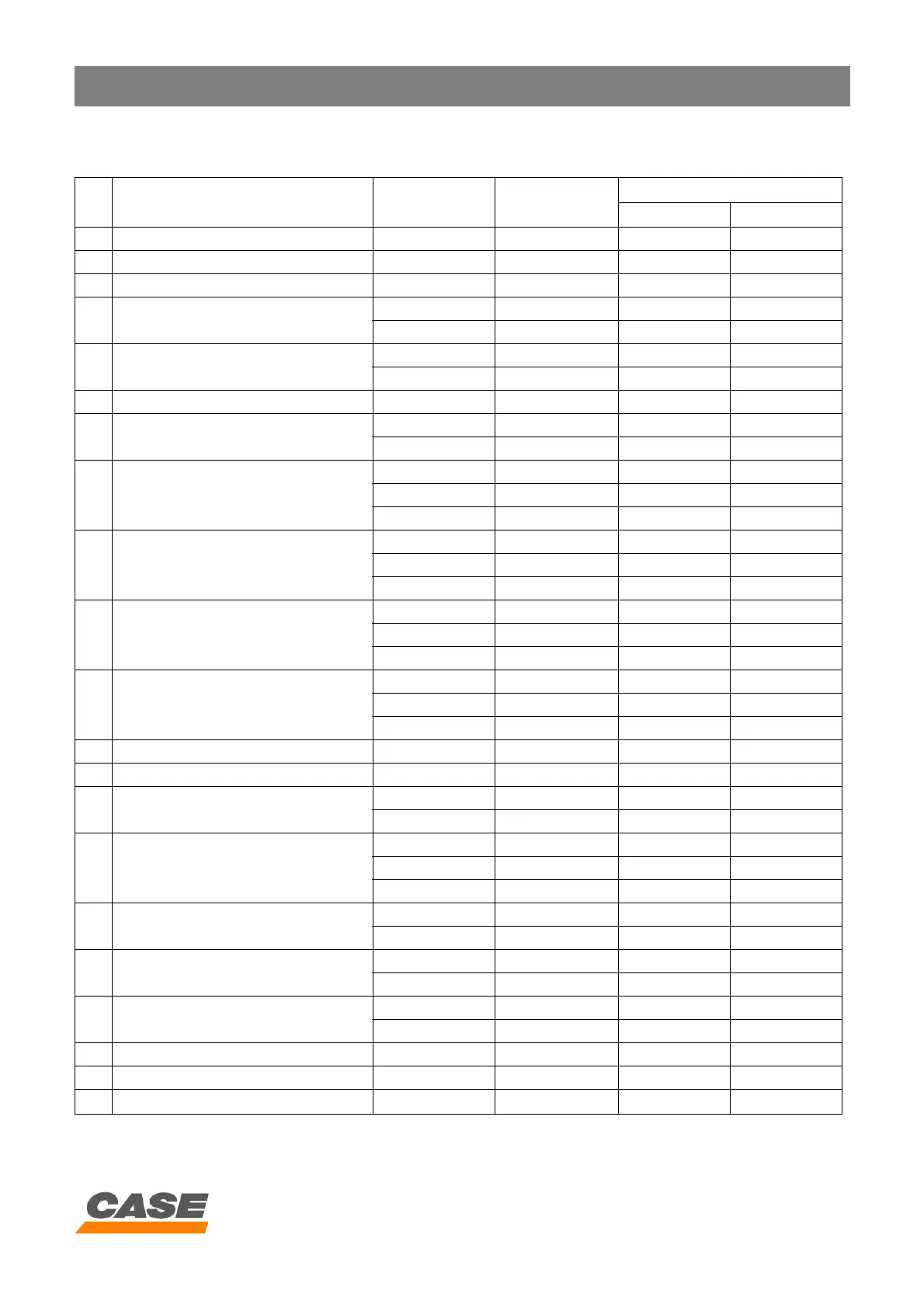

SPECIAL TORQUE SETTINGS

Nota: Use Loctite 262 or an equivalent on retaining screws of components marked with an asterisk (*).

N Component Screw (Ø) Key (mm) Torque setting (Nm)

CX130 CX210

1 * Travel motor/reduction gear assembly M16 24 267-312 267-312

2 * Sprocket M16 24 267-312 267-312

3 * Idler wheel M16 24 267-312 267-312

4 * Upper roller M16 24 267-312 -

M20 30 - 521-608

5 * Lower roller M16 27 267-312 -

M18 27 - 371-432

6 Chain guide M18 27 - 380-443

7 Track pad M16 24 392-430 -

M20 30 - 300 + 120°

8 Counterweight M27 41 844-980 -

M27 41 - 1058-1235

M30 46 - 1333-1549

9 Turntable (undercarriage) M16 24 280-322 -

M20 30 - 468-545

M24 36 - 783-913

10 Turntable (upperstructure) M16 24 280-322 -

M20 30 - 468-545

M24 36 - 783-913

11 * Swing motor/reduction gear assembly M16 24 280-322 -

M20 30 - 521-608

M24 36 - 783-913

12 * Engine M16 24 265-313 265-313

13 * Engine support M10 17 64-73 64-74

14 Radiator M12 19 64-73 -

M16 24 - 147-176

15 * Hydraulic pump M10 17 63-72 -

M10 17 - 64-74

M20 - 367-496

16 * Hydraulic reservoir M16 24 206-247 -

M16 24 - 232-276

17 * Fuel tank M16 24 206-247 -

M16 24 - 232-276

18 * Control valve M16 24 267-312 267-312

M12 19 88-107 -

19 * Hydraulic swivel M12 19 109-127 109-127

20 Cab M16 24 78-80 78-80

21 Battery M10 17 20-29 20-29

Loading...

Loading...