Issued 03-16

1001-6

STANDARD TORQUE DATA FOR CAP SCREWS AND NUTS

Bolt and nut tightening

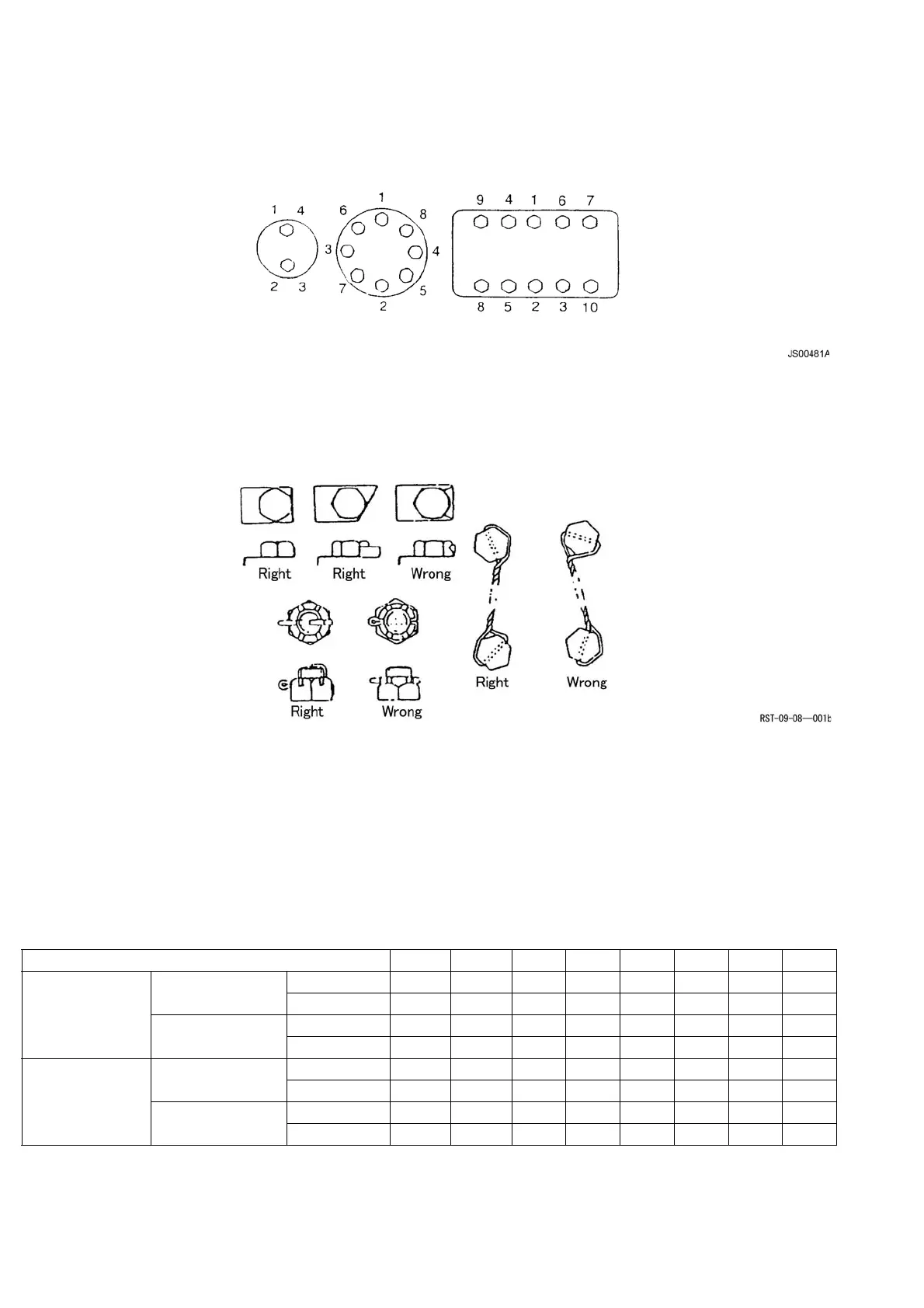

• Tighten alternating between left and right and top and bottom so that uniform tightening force is applied.

• For bolts at critical locations, apply engine oil to the threads for a uniform tightening force without catching on the

thread peaks.

• For bolts and nuts at critical locations and at locations that cannot be inspected from the outside, use wire, cotter

pins, folded washers, or the like to securely prevent turning.

• If Loctite was used on a removed bolt (there is something white sticking to the bolt when it is removed), clean the old

Loctite off with cleaning fluid, dry the bolt, then apply 2 - 3 drops of Loctite to the thread section of the bolt.

Bolt and nut retightening [after 1st 50 Hr. for new machine] [every 250 Hr.]

Tighten and retighten bolts and nuts in each section according to the table. Also before and after day-to-day work,

inspect for loose or fallen out bolts and nuts. Retighten any that are loose and replace any that have come out.

Inspect and retighten after the first 50 hr. for a new machine and every 250 hr. after that.

Torque table

Tighten cap screws and nuts according to the table below if there are no other special instructions.

Cap Screw Name size (Size) M6 M8 M10 M12 M14 M16 M18 M20

Cap Screw

Spanner

[mm] 10 13 17 19 22 24 27 30

[in.] 0.39 0.51 0.67 0.75 0.87 0.95 1.06 1.18

Tightening torque

[Nm] 6.9 19.6 39.2 58.8 98.1 156.9 196.1 294.2

[lb-ft] 5.1 14.5 28.9 43.4 72.3 115.7 144.6 217

Socket Head Cap

Screw

Spanner

[mm] 5 6 8 1012141417

[in.] 0.20 0.24 0.32 0.39 0.47 0.55 0.55 0.67

Tightening torque

[Nm] 8.8 21.6 42.1 78.5 117.7 176.5 245.2 343.2

[lb-ft] 6.5 15.9 31.1 57.9 86.9 130.2 181 253.2

Loading...

Loading...