SECTION 3 - LUBRICATION AND MAINTENANCE

3-4

CHECKING HYDRAULIC CONNECTIONS

Check that all hoses and adapters have been

tightened and that they do not leak.

Repairing Hydraulic Cylinders

Disassembly, repair and assembly of hydraulic

cylinders requires special tools to prevent damage to

internal components. We recommend that a cylinder

that needs repair should be repaired by an

authorized dealer.

Checking Loader Frame Hardware

Hardware torque should be checked immediately

after installation, and several times after a short

period of use. Improperly tightened hardware may

cause structural damage to loader and/or tractor.

Check that all capscrews are tightened to the

specified torque, after 10 hours of operation and then

every 50 hours of operation. Please refer to the table

below for torque values.

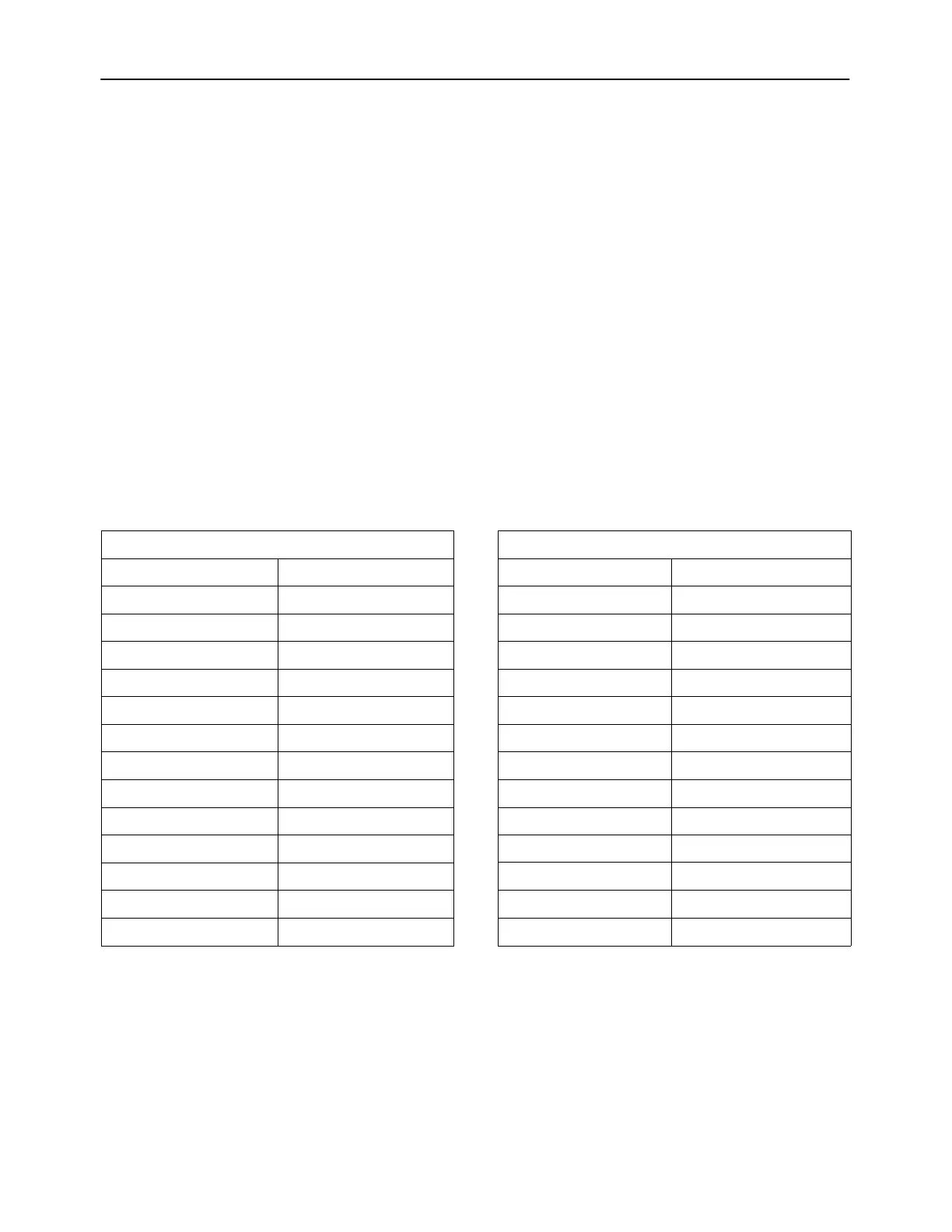

Hardware Tightening Chart

Tighten all the capscrews on the loader and

mounting bracket hardware to the values specifiec in

the table below, except in the cases where the

tightening torque is specified in the assembly

instructions.

The torques specified below apply to clean, dry

threads. Lubricated threads will result in the fastener

being overtightened. Damaged or dirty threads result

in undertightened.

A torque multiplier may be needed when tightening

capscrews to high torque values.

Grade 5 (Class 8.8) Ca pscrew

Diameter Torque

1/4 in 10 ft-lb (13.6 N⋅m)

5/16 in 20 ft-lb (27.1 N⋅m)

3/8 in 35 ft-lb (47.5 N⋅m)

7/16 in 55 ft-lb (75 N⋅m)

1/2 in 85 ft-lb (100 N⋅m)

5/8 in 170 ft-lb (230 N⋅m)

3/4 in 300 ft-lb (405 N⋅m)

M8 27.1 N⋅m (20 ft-lb)

M10 54.2 N⋅m (40 ft-lb)

M12 94.9 N⋅m (70 ft-lb)

M14 119.3 N⋅m (88 ft-lb)

M16 189.8 N⋅m (140 ft-lb)

M20 264.4 N⋅m (195 ft-lb)

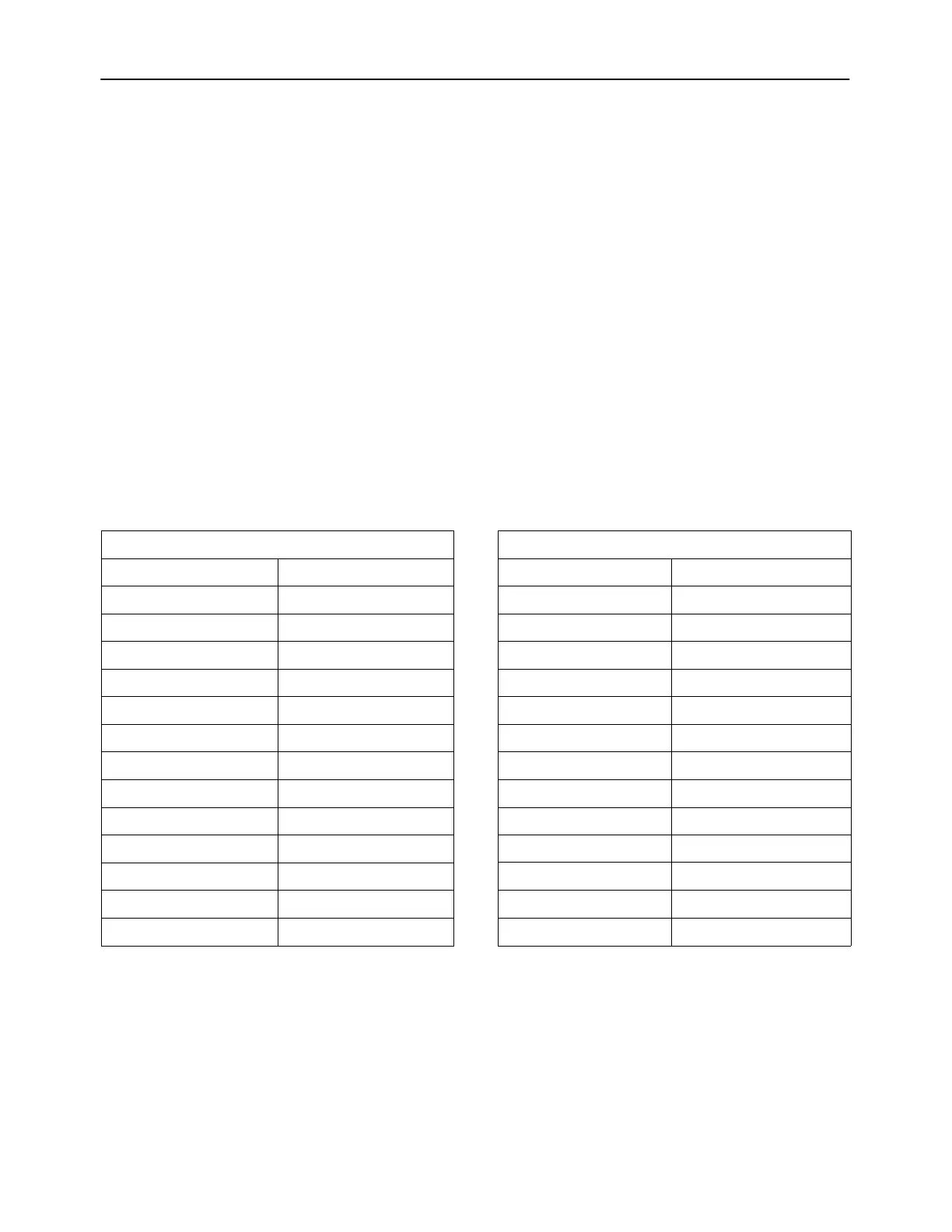

Grade 8 (Class 10.9) Capscrew

Diameter Torque

1/4 in 11 ft-lb(14.9N⋅m)

5/16 in 24 ft-lb (32.5 N⋅m)

3/8 in 44 ft-lb (59.7 N⋅m)

7/16 in 71 ft-lb (96.3 N⋅m)

1/2 in 114 ft-lb (154.6 N⋅m)

5/8 in 222 ft -lb (301 N⋅m)

3/4 in 325 ft-lb (440.6 N⋅m)

M8 32.5 N⋅m(24 ft-lb)

M10 63.7 N⋅m(47 ft-lb)

M12 108.4 N⋅m(80 ft-lb)

M14 176.3 N⋅m (130 ft-lb)

M16 271.2 N⋅m (200 ft-lb)

M20 542.3 N⋅m (400 ft-lb)

Loading...

Loading...