SECTION 4 - TROUBLESHOOTING

4-2

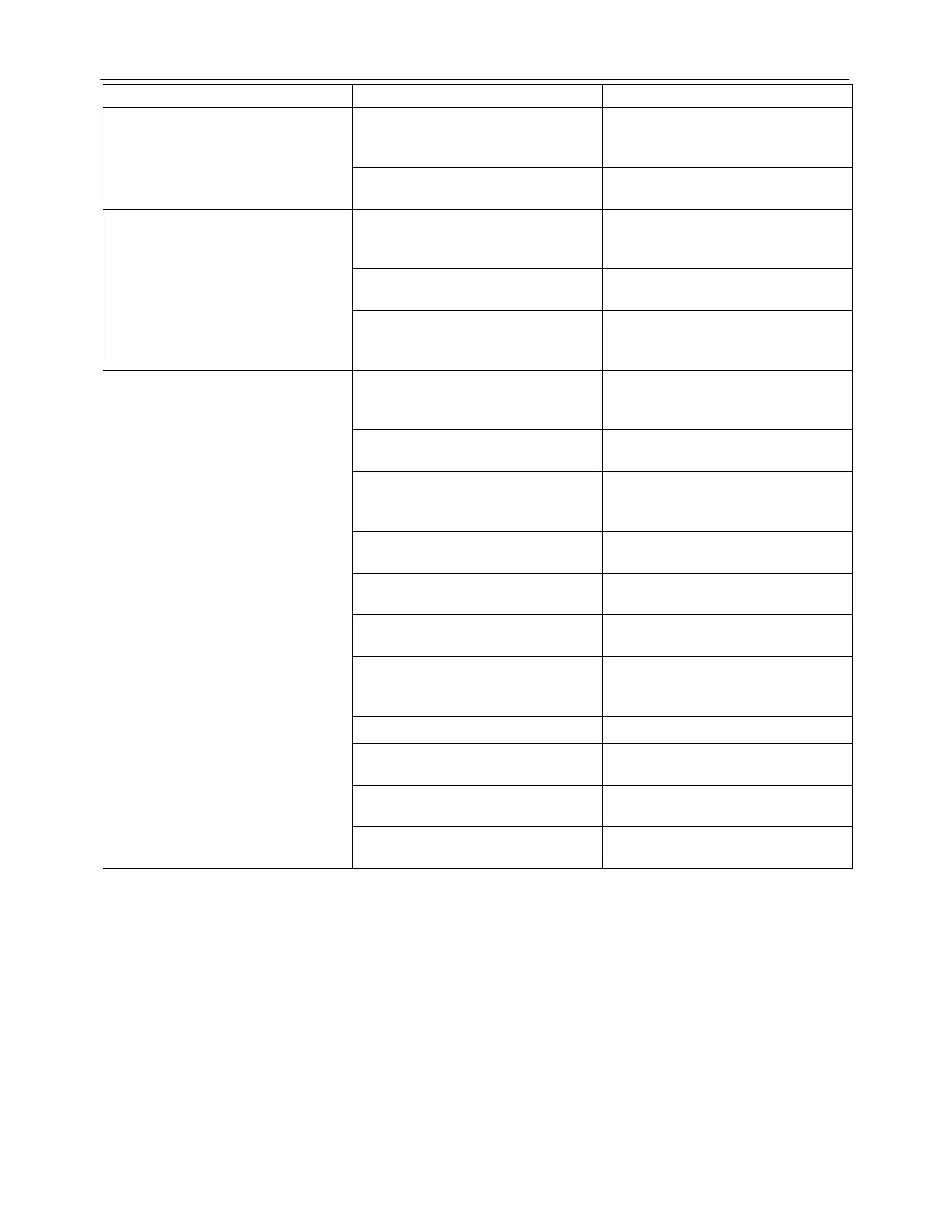

Problem Possible cause Action

Lift and/or bucket cylinders oper-

ate in wrong direction compared

with lever movement

Hydraulic hoses wrongly con-

nected.

Connect hydraulic hoses to cor-

rect union.

Control cables for single lever

control wrongly connected.

Contact your dealer.

Air in hydraulic oil (generally

shown by

foaming)

Low hydraulic oil level. Check and top up with hydraulic

oil to correct level.

Air leakage in hydraulic pump suc-

tion side.

Contact your dealer.

Foaming due to use of wrong type

of oil.

Read the tractor instruction manu-

al and use the recommended type

of hydraulic oil.

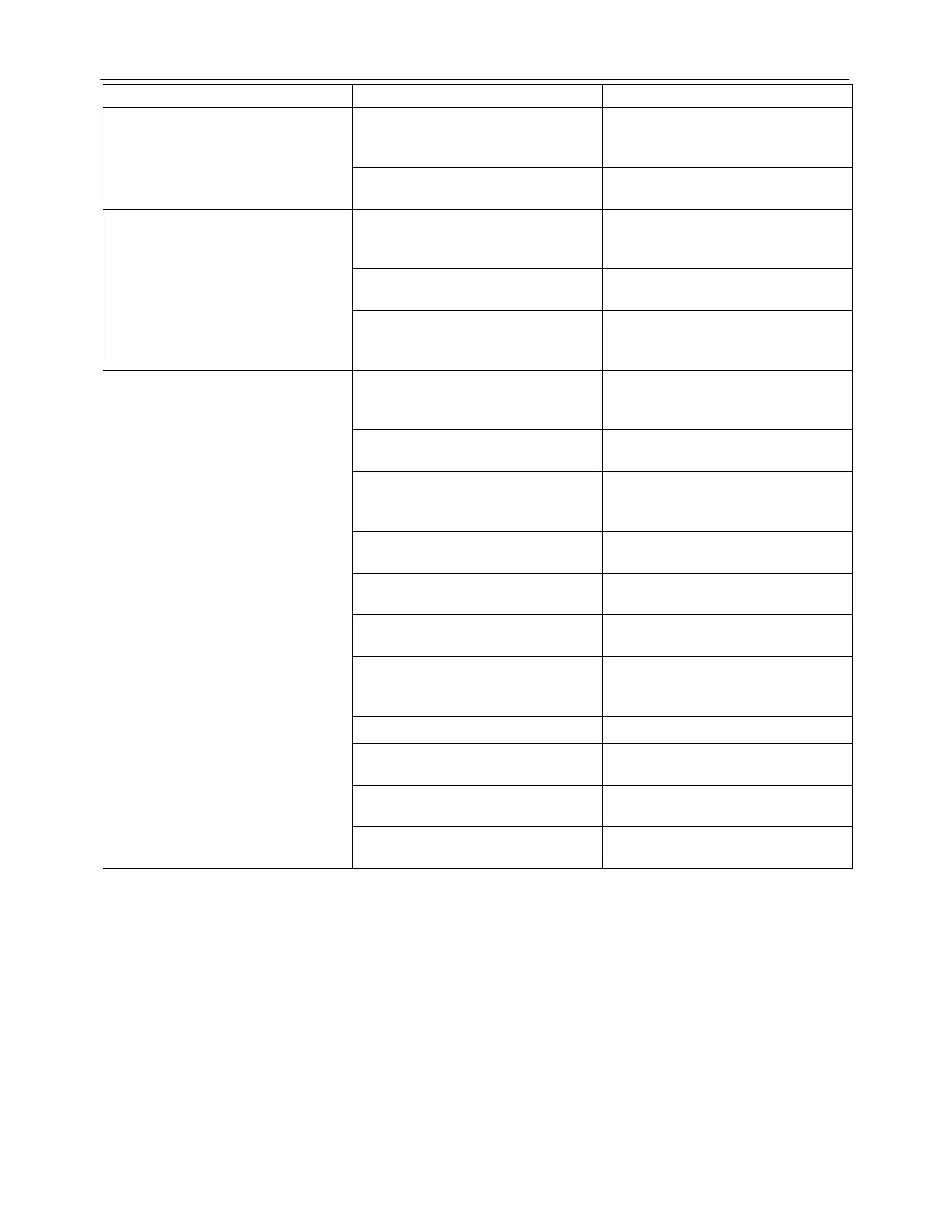

Slow or jerky lifting movement Low hydraulic oil level. Cold hy-

draulic oil.

Check/top up the hydraulic oil. Let

the hydraulic oil warm up to work-

ing temperature.

Engine speed too low (hydraulic

pump speed is then too low).

Increase engine speed to improve

loader performance.

Too heavy load in bucket. Material

weight exceeds loader’s specified

capacity.

Reduce the load in the bucket.

Control valve cable system binds

or is damaged.

Contact your dealer.

Air in the hydraulic oil. Please refer to ”Air in hydraulic oil”

above.

Hydraulic quick--release couplings

not fully inserted.

Check the couplings. Repair or

change.

Restriction in hydraulic hose or

pipe (hoses/pipes have become

twisted or crushed).

Check hoses/pipes for signs of re-

striction.

Lifting cylinder piston unit leaks. Contact your dealer.

Reduction valve works unevenly

or is set too low.

Contact your dealer.

Internal leakage in control valve

(bypass flow in valve).

Contact your dealer.

Low capacity in hydraulic pump. Please refer to “Low pump capac-

ity” below.

Loading...

Loading...