CEBORA S.p.A. 13

3.3.6 - Gas flows from the torch, the pilot arc does not light (nozzle voltage missing).

WARNING

FOR THE FOLLOWING TESTS DISCONNECT TERMINALS J5 AND J6 ON CONTROL

BOARD (6) TO

PREVENT HIGH FREQUENCY FROM BEING GENERATED.

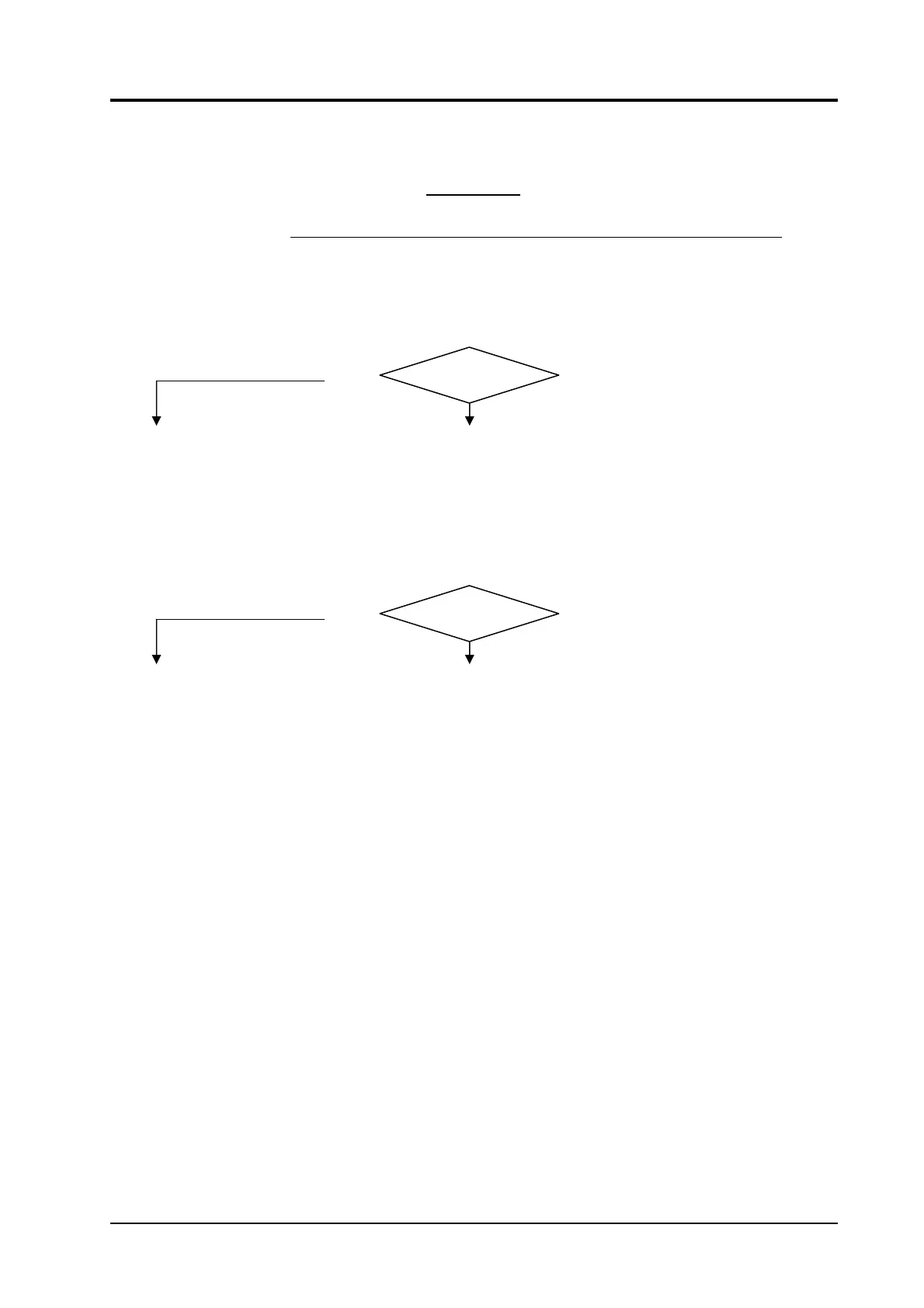

POWER SOURCE OUTPUT VOLTAGE TEST.

Correct?

Output terminal (21) of the power source (+) (workpiece potential) and HF transformer (31)

secondary winding terminal (-) (electrode potential) = +250 Vdc approximately, with start

button pressed, for a duration of approximately two seconds (maximum pilot arc time).

YES

NO

♦ Go to par. 3.3.7.

♦ Power source output voltage regular.

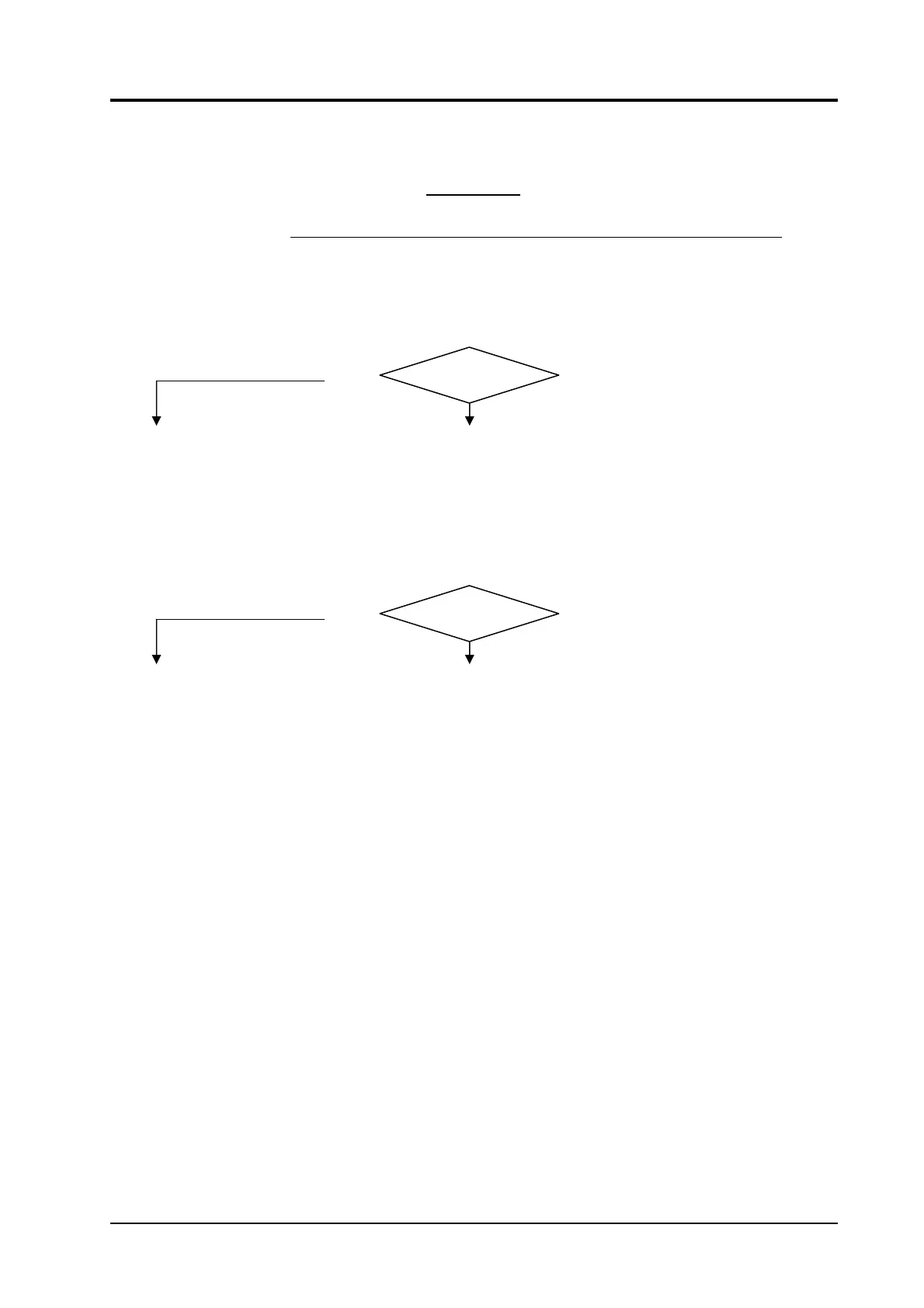

NOZZLE VOLTAGE TEST.

Correct?

Terminal TP8 on HF-filter board (47)(+) (nozzle potential) and HF transformer (31)

secondary winding terminal (-) (electrode potential) = +250 Vdc approximately, with start

button pressed, for a duration of approximately two seconds (maximum pilot arc time).

NO

YES

♦ Check the wiring between rectifier (32) negative terminal, HF transformer (31)

secondary winding terminal and torch cable electrode terminal, and between

rectifier (32) positive terminal, resistors (37), HF-filter board (47) and torch cable

nozzle terminal. If you find loose connections, tighten and replace any

components with damaged terminals.

♦ Check condition of torch cable and torch, especially make sure there are no short-

circuits or insulation leaks between the conductors or between electrode, nozzle,

nozzle holder and diffuser.

♦ With power source off, check the resistance of resistors (37). Corrected values = 1

ohm and 2,4 ohm. If not correct replace resistors (37).

♦ Replace HF-filter board (47).

♦ Check connection between torch cable and HF transformer (31) secondary winding, and TP8

on HF-filter board (47). If you find loose connections, tighten and replace any components

with damaged terminals.

♦ Make sure the internal parts of the torch are properly isolated, including the cables, and if in

doubt replace the entire torch.

♦ Check the electrode, swirl ring and torch nozzle; replace if worn or damaged.

♦ Make sure HF generator working condition, performing if necessary test of par. 3.3.5.

♦ Check correct gas flux in the torch, performing if necessary PLASMA GAS PRESSURE

TEST in par. 3.3.8.

3.302.173 28/07/04

Loading...

Loading...