29

ENGLISH

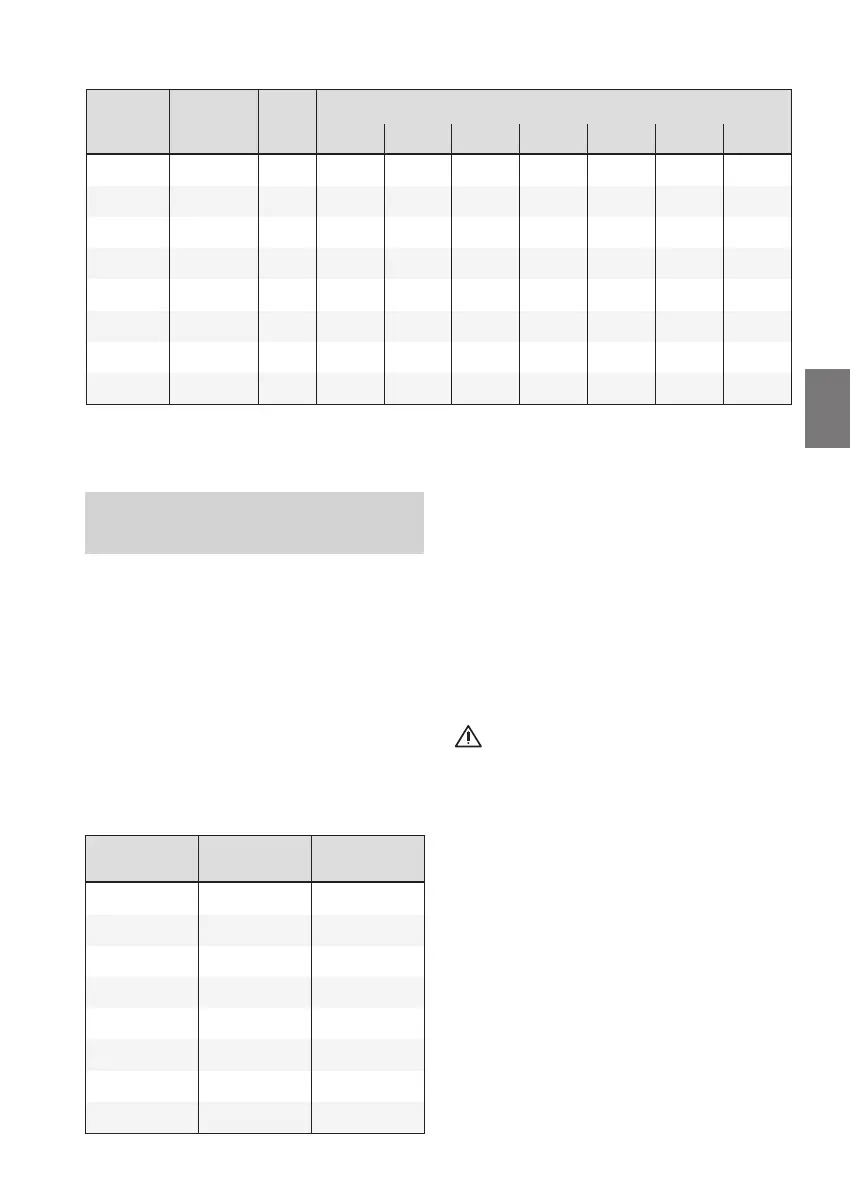

Table 4A - Adjusting the braking torque

Frame

size

Brake

type

A

0

[mm]

Braking torque [Nm] for A =

A

0

A

0

+1mm A

0

+2mm A

0

+3mm A

0

+4mm A

0

+5mm A

0

+6mm

63

AC1 0 4,5 --- --- --- --- --- ---

71

MEC 63 14 9,0 6,0 3,0 --- --- --- ---

80

T80 12 17,0 13,5 10,0 6,5 --- --- ---

90

MEC80 18 35,0 32,0 29,5 27,0 24,0 21,5 18,5

100

MEC90(

◆

)

17 48,0 42,0 36,0 30,0 24,0 18,0 12,0

112

MEC100(

◆

)

20 70,0 57,0 44,5 32,0 19,0 --- ---

132

MEC112(

◆

)

23 90,0 77,0 63,0 49,0 35,5 21,5 ---

160

T140(

◆

)

23 130,0 110,0 90,0 70,0 55,0 35,0 ---

A

0

= distance for the standard braking torque value

(

◆

) = 2 braking disks available on request

The recommended air gap, with a tolerance of ± 0,05

mm is shown in table 4B.

The air gap

Y

(fig. 2C and 2D) is the gap between

the faces of the electro-magnet and the mobile arma-

ture, when the brake is not powered (motor brake on).

This value must be adjusted when, due to wear on

the brake disc friction material, the air gap increases

beyond the values shown in table 4B, affecting the

brake’s performance.

The maximum acceptable air gap under maximum

torque conditions is 0,7 mm.

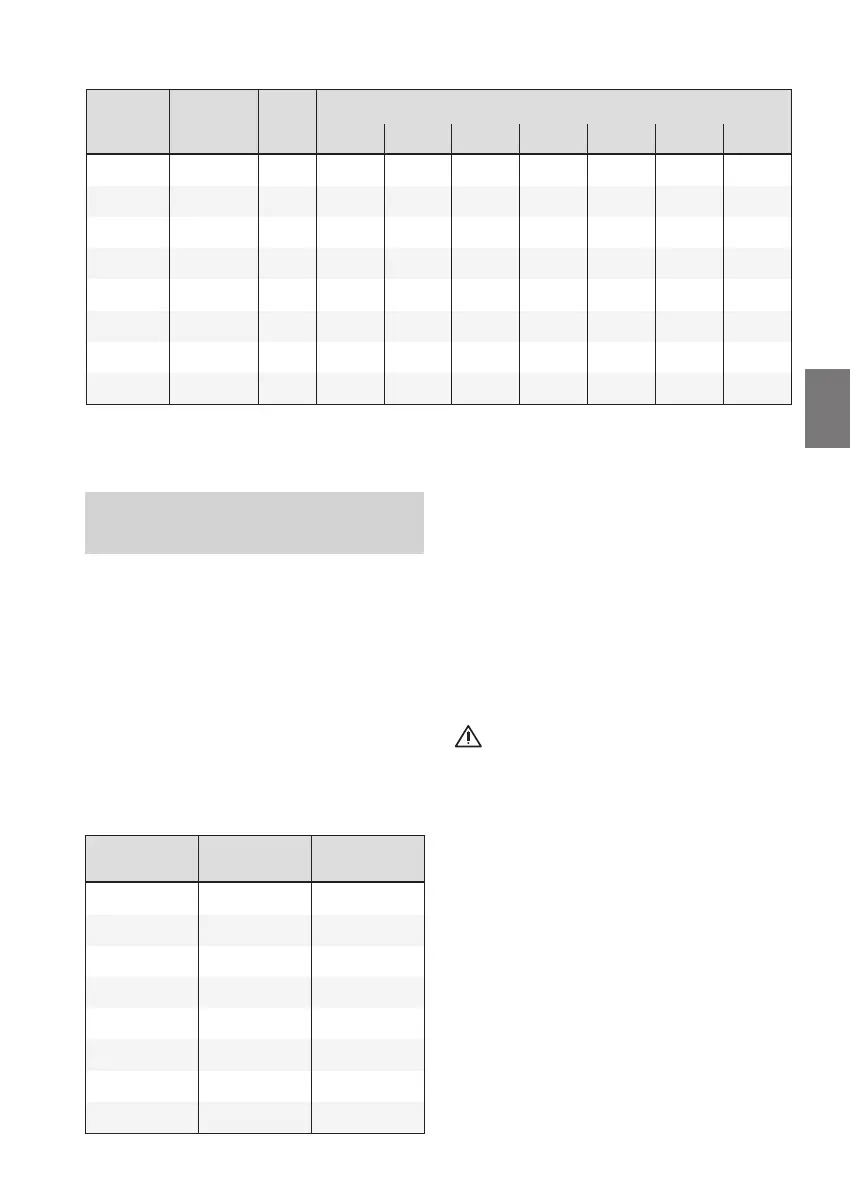

Table 4B - Recommended air gap

For size 71÷160 motors (fig. 2C) the air gap is

adjusted by turning the nuts

fk

A and

fk

B to move

the electro-magnet to the original gap from the

mobile armature.

For size 63 motors (fig. 2D) the air gap is adjusted by

turning the fixing screws

es

after having slackened

the adjustment nuts

fk

A. Once the required gap has

been set, the adjustment nuts must be tightened

against the single unit.

Before carrying out this operation make sure that

the brake casing has not overheated.

Failure to adjust the air gap may result in the

brake not opening properly, which in turn results

in the motor and the brake heating up.

For motors with a manual release, if the air gap

exceeds the maximum value, rotating the release

spanner may not be sufficient to adequately

release the brake.

Frame

size

Brake

type

Air gap

[mm]

63

AC1 0,2

71

MEC 63 0,3

80

T80 0,3

90

MEC80 0,3

100

MEC90 0,3

112

MEC100 0,3

132

MEC112 0,5

160

T140 0,3

4.4 Adjusting the air gap

motors 63÷160

Loading...

Loading...