CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

Remove any protective flange covers from the valve.

Inspect the valve to be certain the waterway is free from

dirt and foreign matter. Be certain the adjoining pipeline is

free from any foreign material such as rust and pipe scale

or welding slag that could damage the seat and disc

sealing surfaces.

Any actuator should be mounted on the valve prior to

installation to facilitate proper alignment of the disc in the

valve seat.

Check the valve identification tag for materials, and oper-

ating pressure to be sure they are correct for the applica-

tion.

Check the flange bolts or studs for proper size, threading,

and length.

INSTALLATION RECOMMENDATIONS

5

Pre-Installation Procedure

1.

2.

3.

4.

5.

Personal injury or property damage

may result if the valve is installed

where service conditions could ex-

ceed the valve ratings.

WARNING!

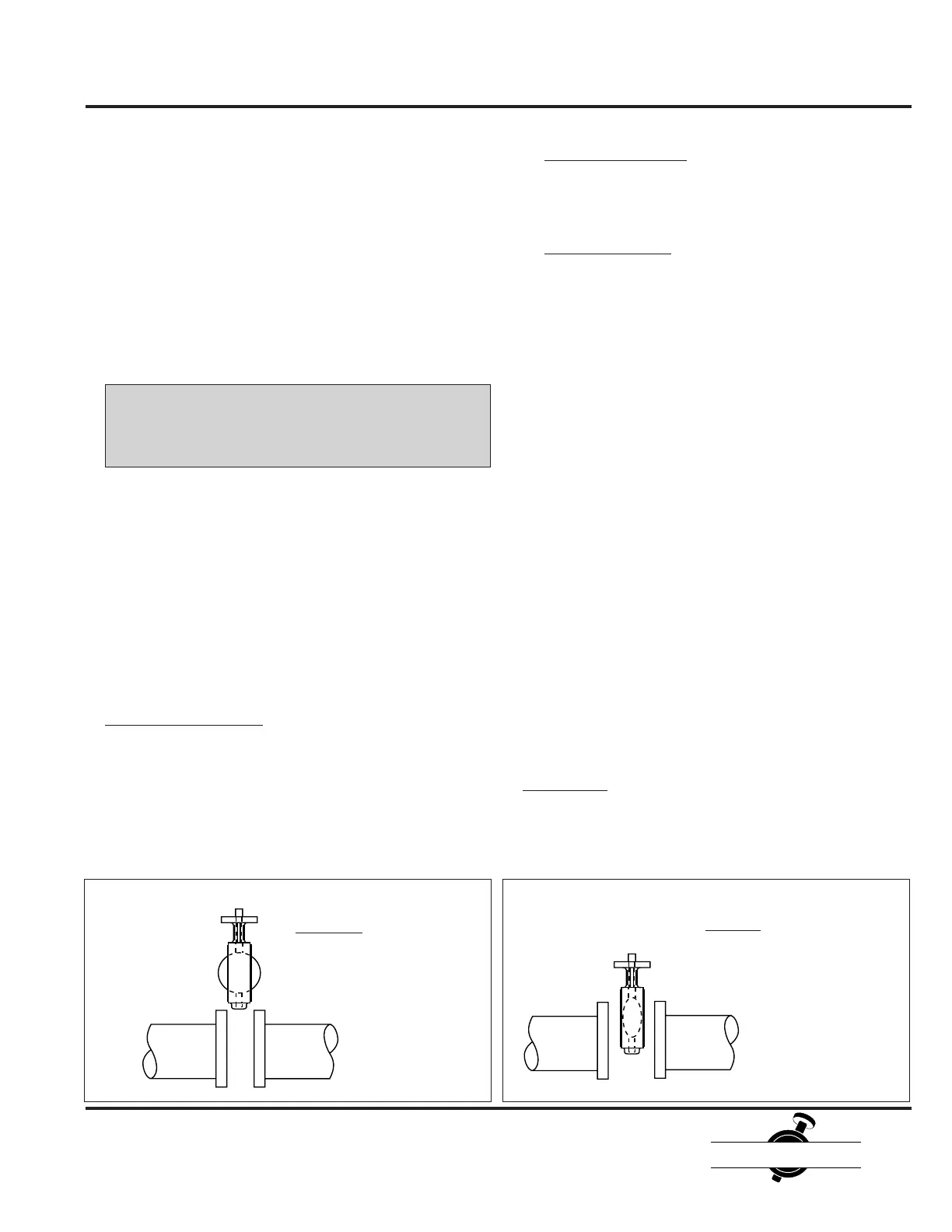

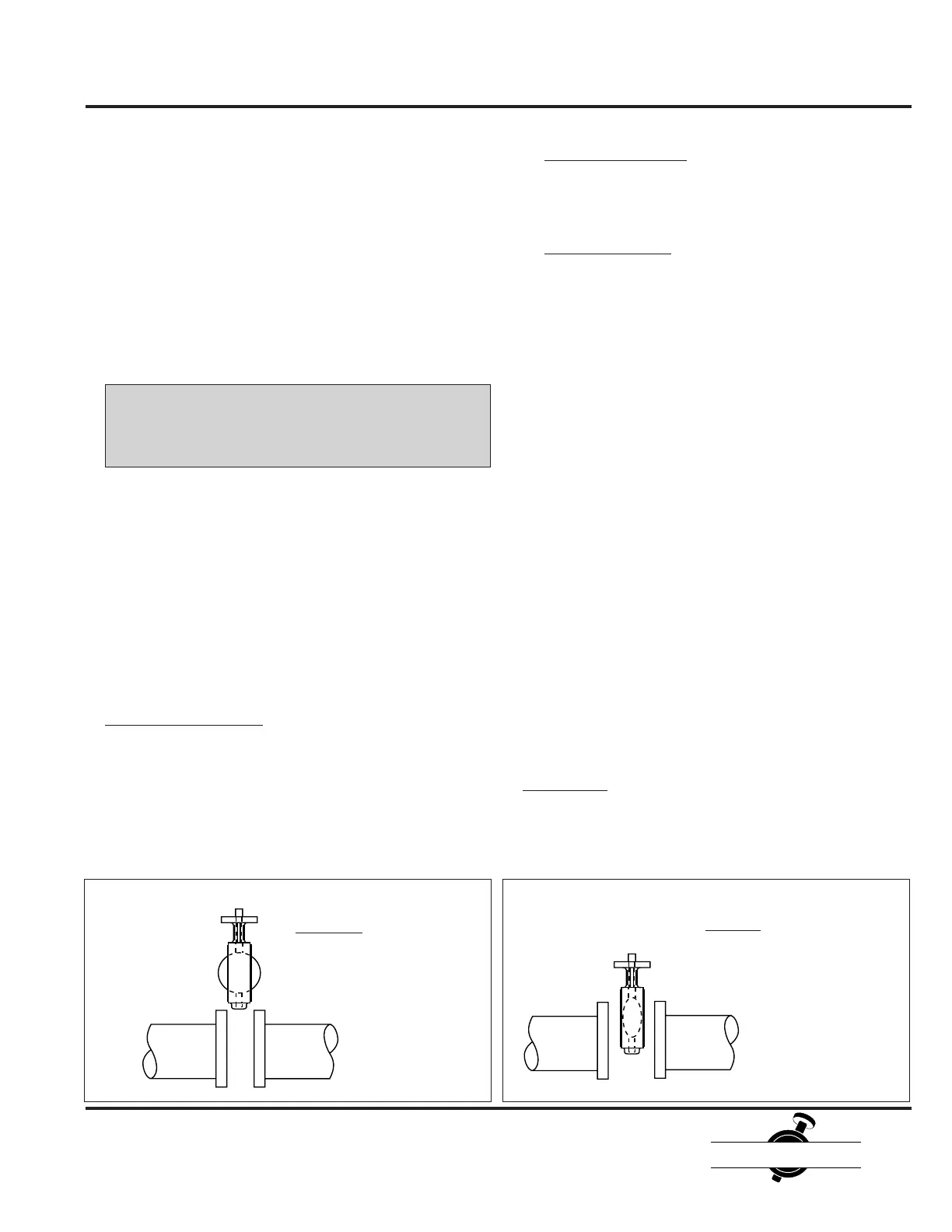

Position the connecting pipe flanges in the line to insure

proper alignment prior to valve installation. Spread the pipe

flanges apart enough to allow the valve body to be located

between the flanges without actually contacting the flange

surfaces (See Figure 1.) Exercise particular care in handling

the valve so as to prevent possible damage to the disc or seat

faces.

Valve Installation Procedure

For Lug style valves:

a. Place the valve between the flanges.

b. Install all bolts between the valve and the mating

flanges. Hand tighten bolts as necessary.

For Check Valves:

a. Note the opening direction of the disc for proper

valve orientation.

b. Place the valve between the flanges using the four

(4) alignment holes provided.

c. Install the remaining flange bolts, shifting the valve

as necessary to permit the bolts to pass by the valve

body. Hand tighten bolts as necessary.

2.

3.

4.

5.

6.

Before completing the tightening of any bolts, the valve

should be centered between the flanges and then

carefully opened and closed to insure free, unob-

structed disc movement (See Figure 2.)

Using the sequence shown in Figure 3, tighten the

flange bolts evenly to assure uniform compression.

If an actuator is to be used, air hoses or electricity

should be connected to the unit as specified by the

actuator manufacturer.

Cycle the valve to the fully open position, then back to

the fully closed position, checking the actuator travel

stop settings for proper disc alignment. The valve

should be operated to assure that no binding is taking

place.

The valve is now ready for operation.

Remember:

Install the valve with the disc in

the “ALMOST CLOSED” position.

Do not use any flange gaskets.

Correct

Disc positioned in the

almost closed position.

Pipe flange spread allows

sufficient room for valve.

Incorrect

Disc opened beyond valve

body face. Pipe flanges not

spread sufficiently.

Figure 1-Initial Installation of Valve

1. For Wafer style valves:

a. Place the valve between the flanges.

b. Loosely install the two upper and lower flange bolts

that pass through the body alignment holes.

c. Install the remaining flange bolts, shifting the valve as

necessary to permit the bolts to pass by the valve

body. Hand tighten all bolts as necessary.

Loading...

Loading...