CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

MAINTENANCE INSTRUCTIONS

SECTION 3

Be sure the line is depressurized and drained.

Be sure of the pipeline media. Proper care should be

taken for protection against toxic and/or flammable

fluids.

Never remove the valve without an Operator (Manual or

Automatic) already attached to the valve shaft.

Never remove the Operator from the valve while the

valve is in the pipeline under pressure.

Always be sure that the disc is in the closed position

before removing the valve.

1.

2.

3.

4.

5.

Thoroughly clean all parts. Inspect components for any

defects.

Apply a small amount of silicone grease to the inside

surfaces of the body, including the upper and lower shaft

holes.

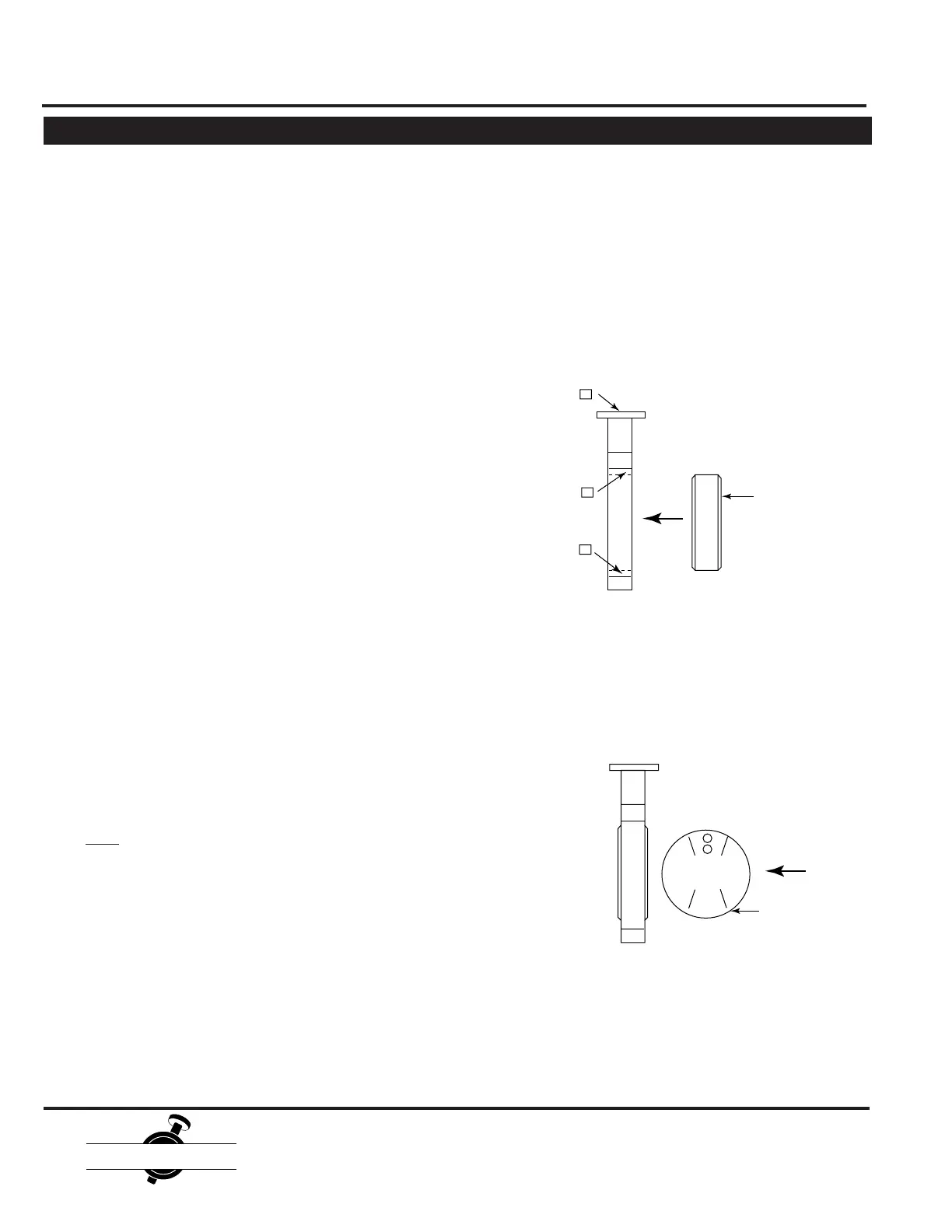

Insert the shaft bushings into the body being careful not to

allow intrusion into the body seat bore.

Install the seat into the center of the body, making sure the

shaft holes in the seat line up with the holes in the body.

1.

2.

3.

4.

8

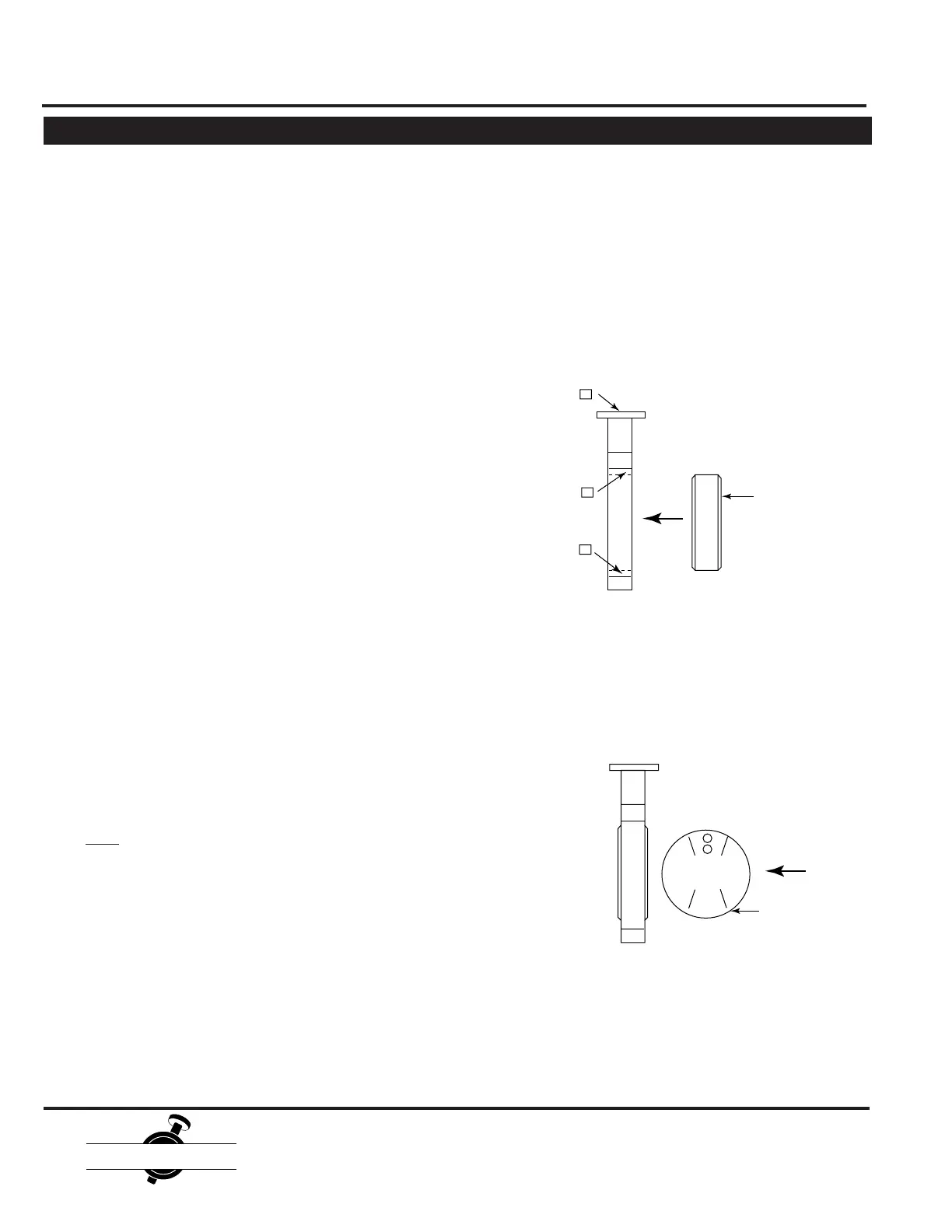

Completely coat the inside surfaces of the seat with

silicone grease. Carefully push the disc into the seat in the

open position (90 degrees to the body.) Line up the shaft

holes of the disc as close as possible with the shaft holes

in the seat body.

5.

Disc

1.

2.

3.

4.

5.

6.

Position valve flat with the disc in the closed position.

Loosen the taper pin(s) from the valve disc using a

hammer and punch.

Note: Punch should be of same size or larger

diameter as small end of taper pin to avoid mush-

rooming of taper pin.

Remove taper pin(s) from disc. Extract the valve shaft

from the body using a twisting motion.

Remove the valve disc from body making sure not to

damage the seat or disc sealing edge.

Cartridge seat removal can be accomplished from ei-

ther direction by applying pressure evenly on one face

to push the seat through the body. If the valve is of dead

end service design, remove set screws around periph-

ery of body extending into seat prior to seat removal.

Remove shaft bushings from body as required.

General Maintenance

The following periodic preventative maintenance practices

are recommended for all Center Line Butterfly Valves.

1.

2.

3.

4.

Operate the valve from full open to full closed to assure

operability.

Check flange bolting for evidence of loosening and

correct as needed.

Inspect the valve and surrounding area for previous or

existing leakage at flange faces or shaft connections.

Check piping and/or wiring to actuators and related

equipment for looseness and correct as needed.

Before removing the valve from the line or loosening any

bolts, it is important to verify the following conditions:

Butterfly Valve Assembly

Safety Precautions

Butterfly Valve Disassembly

Loading...

Loading...