CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

3

4

6

6

2

1

2

5

7

5

8

8

1

MAINTENANCE INSTRUCTIONS

1.

2.

3.

4.

5.

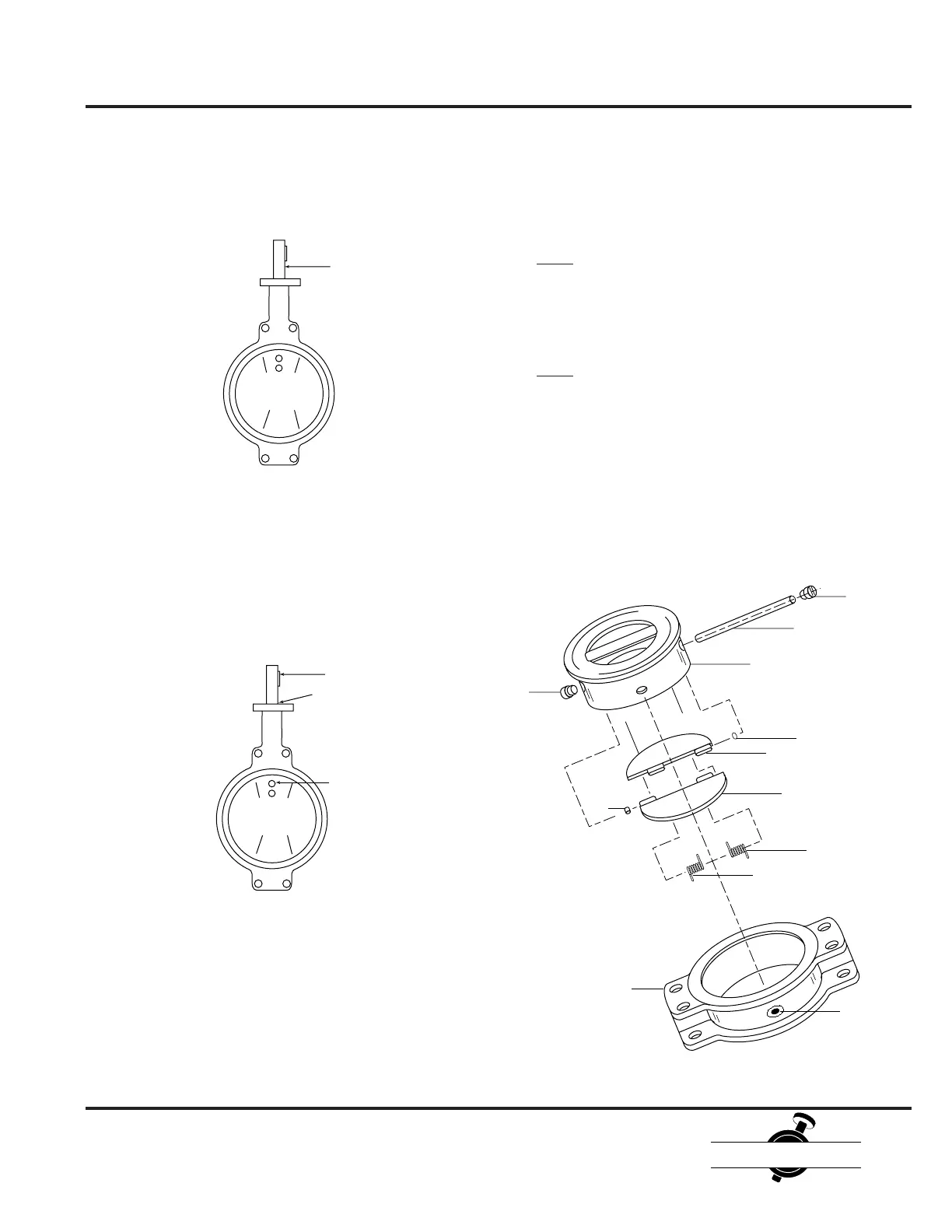

Check Valve Disassembly

Remove set screw (7) from the alignment body (1).

Remove the valve insert (4) from the alignment body (1).

Remove shaft plugs (8) from the insert with a screwdriver.

Note: Plugs are sometimes difficult to loosen. When this

happens, apply heat with small torch directly to the plug for

30 seconds. Do not allow the flame to touch the elastomer

face on either side of the inset.

Remove the shaft (3) from the valve insert.

Note: When the stem is removed, the springs (5) behind

the check plates (2) will be released. On sizes 8" to 20",

these springs must be securely held to prevent recoil upon

loss of tension.

Remove the check valve plates (2) from the valve insert.

Note the location of the thrust washers (6). These must be

replaced in the same location upon reassembly.

Butterfly Valve Assembly

(continued from page 8)

6.

7.

8.

9

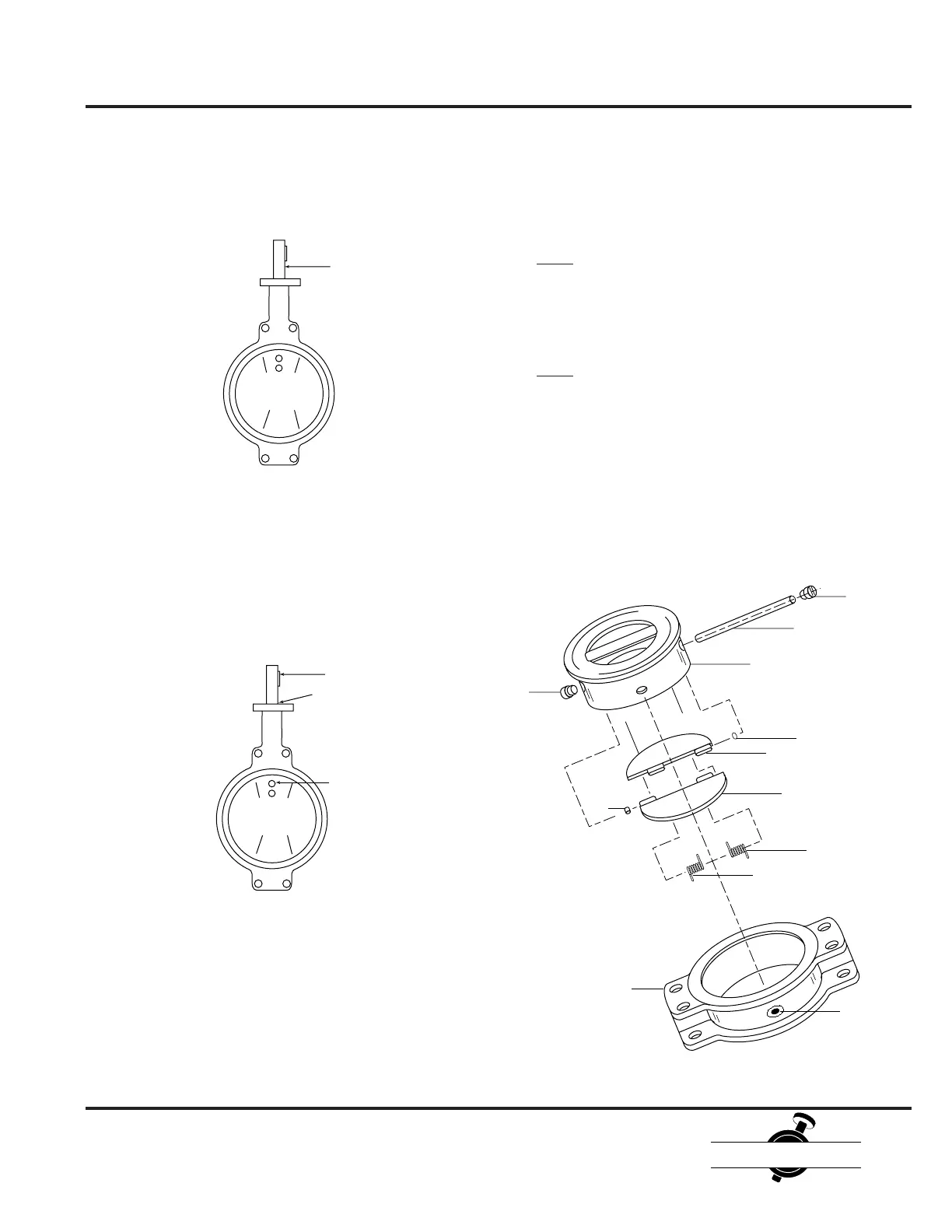

Insert the shaft through the body and disc, use a twisting

motion to align the keyway parallel with the disc.

Shaft

Insert taper pin(s) into the disc and set with two or three

sharp blows. Wipe dust shield o-ring with silicone grease

and place over the shaft into the top of the body.

If the valve is of dead end service design, insert set screws

through the body into the seat.

Key

Taper Pins

O-Ring

Loading...

Loading...