Do you have a question about the Central Pneumatic 42321 and is the answer not in the manual?

Emphasizes the critical importance of reading and understanding all instructions before operating the equipment.

Instructs the user to retain the manual and invoice for future reference and warranty purposes.

Maintain a clean, well-lit workspace, avoid explosive atmospheres, and keep bystanders away.

Ensure proper grounding, avoid wet conditions, handle cords carefully, and do not use extension cords.

Stay alert, dress properly, prevent accidental starts, and keep clear of moving parts.

Use the correct compressor, maintain it properly, and check for damage before use.

Use manufacturer-recommended accessories and have service performed by qualified personnel.

Includes oil fill, eye/ear protection, tool ratings, and power disconnection for maintenance.

Covers oil fill, protection, tool ratings, maintenance safety, air jet direction, and safety valve checks.

Details on avoiding pressure switch adjustments and proper air output control.

Instructions on draining tanks, avoiding modifications, and using approved air hoses.

Highlights the need for a dedicated electrical circuit to avoid overloading.

Covers power failure, line voltage variations, labels, pacemaker interference, and lead content.

Instructions on checking and filling the oil reservoir with the correct type and amount of oil.

Guidance on connecting an air intake filter, oiler, and air hoses to the compressor.

Step-by-step guide for starting the compressor, including pre-checks and pressure build-up.

Information on pressure switch adjustments and controlling air output via the air flow valve.

Routine maintenance includes checking oil levels, replacing oil annually, and cleaning the air filter.

Instructions for draining tanks after use and cleaning the compressor unit.

Lists components and quantities for the main assembly, including notes on part availability.

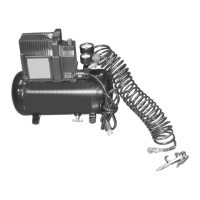

Diagram illustrating the assembly of major components labeled in Parts List 'A'.

Comprehensive list of internal and external parts with item numbers and quantities.

Detailed schematic showing the exploded view of internal components for Assembly 'B'.

| Tank Capacity | 3 Gallon |

|---|---|

| Max Pressure | 125 PSI |

| Voltage | 120V |

| Type | Portable |

| Horsepower | 0.8 HP |