Page 4 For technical questions, please call 1-800-444-3353. SKU 46149

PRESSURIZATION, check to make

sure the Ball Valve (4) is fully closed

(with its Handle in the horizontal

position). If this does not correct the

problem remove the unit from service

immediately and have it repaired by a

qualied repair service technician.

DISCONNECT AIR SUPPLY AFTER 7.

EVACUATING OIL.

USE ONLY THE HOSE/NOZZLE 8.

ASSEMBLY (5) PROVIDED. Do not

attempt to modify the Hose/Nozzle

Assembly in any way.

THE AIR RELEASE VALVE HAS 9.

BEEN PRE-INSTALLED AND

PRESET TO OPERATE AT 70-110

PSI. Do not tamper with or remove.

DO NOT DRAIN CAUSTIC OR 10.

FLAMMABLE PRODUCTS. Do not

expose tank to heat or any ignition

source. Do not do any welding on

or around tank. When removing oil

keep hands and face protected to

prevent against possible burns.

WARNING: The brass components 11.

of this product contain lead, a

chemical known to the State of

California to cause birth defects (or

other reproductive harm).

(California Health & Safety code §

25249.5, et seq.)

T12. he warnings, cautions and

instructions discussed in this

instruction manual cannot cover

all possible conditions and

situations that may occur. It must

be understood by the operator that

common sense and caution are

factors which cannot be built into

this product, but must be supplied

by the operator.

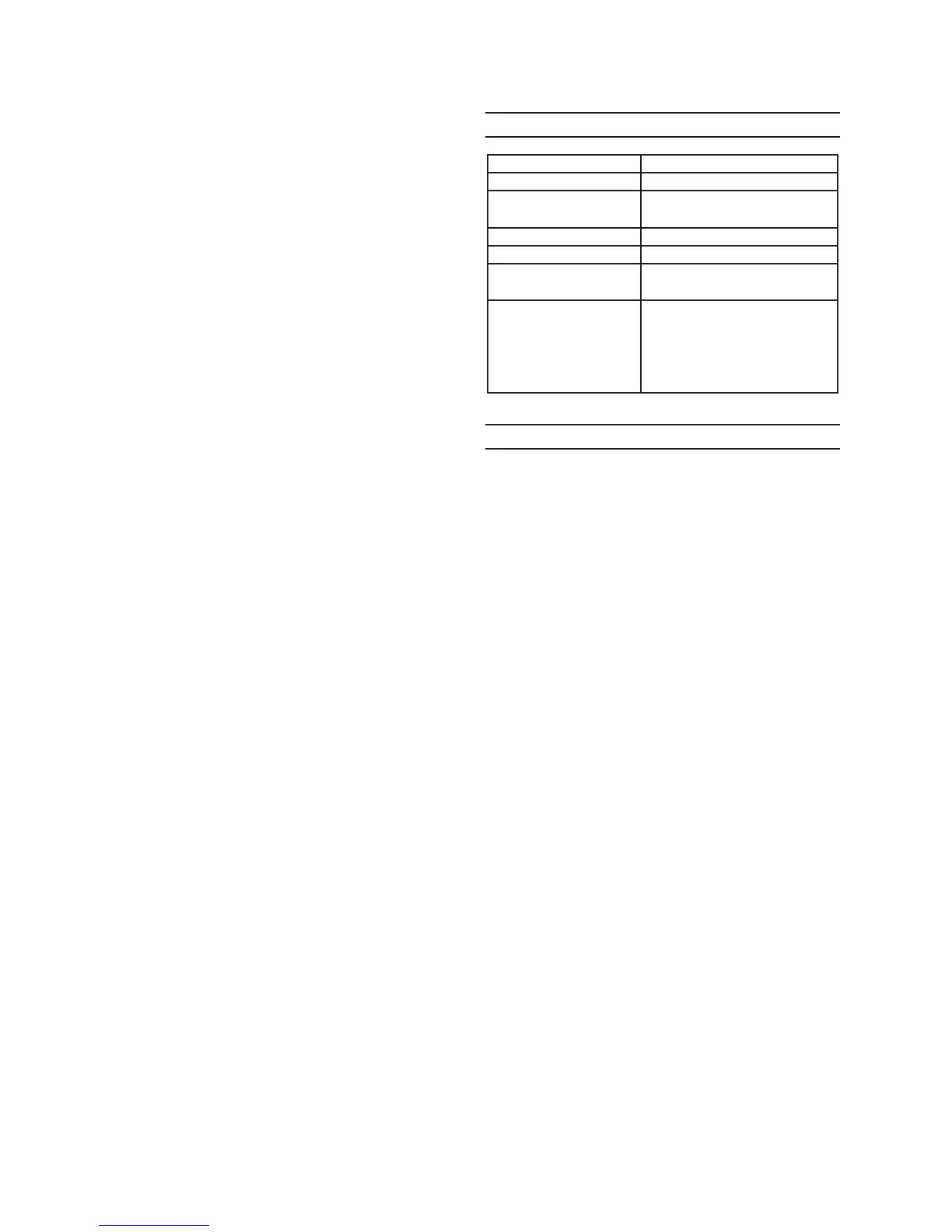

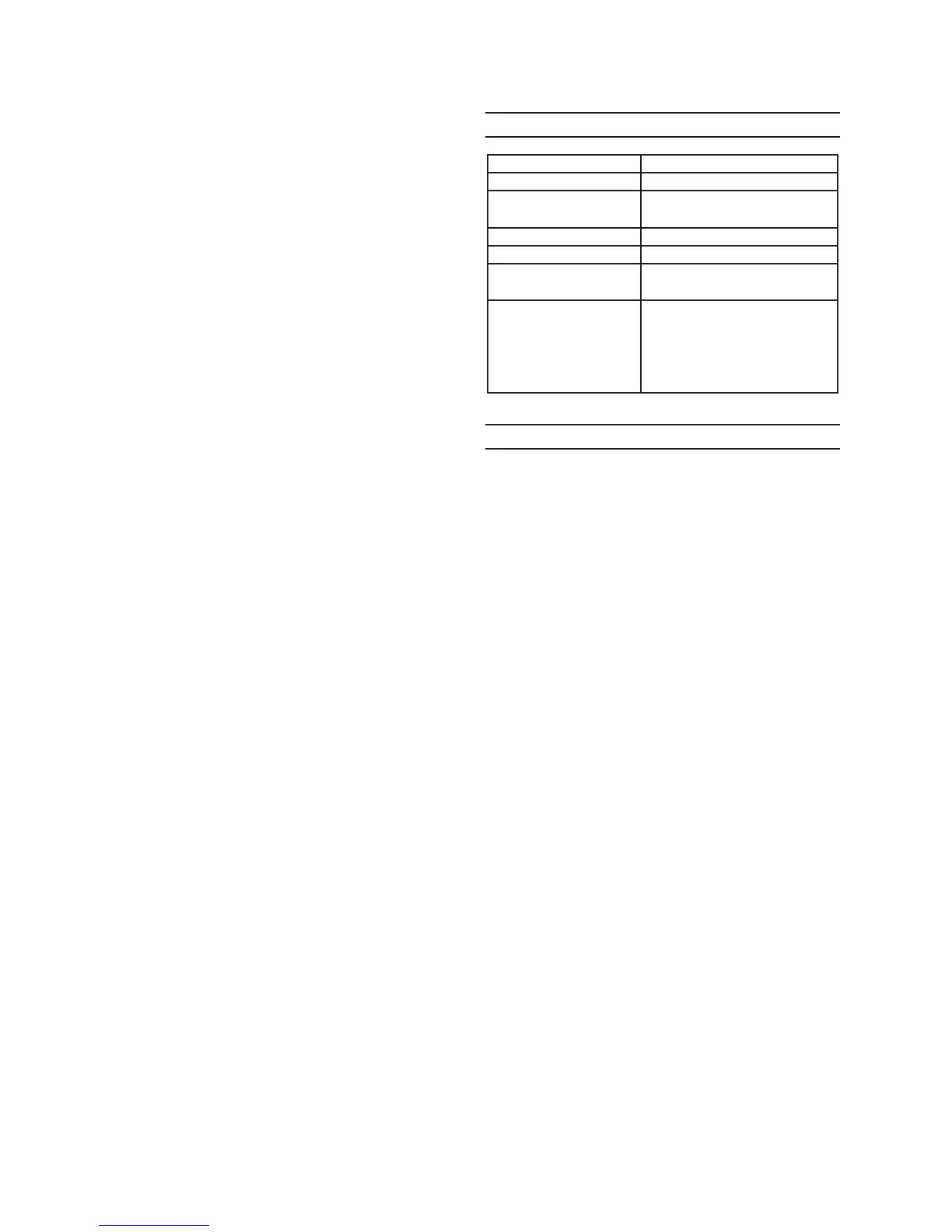

SPECIFICATIONS

Tank Reservoir Size 6-1/4 Gallons

Maximum Oil Level 4-1/4 Gallons

Maximum extraction

rate

1/2 GPM

Air Inlet 1/4” NPT

Working Air Pressure 70-110 PSI

Min/Max. Oil

Temperature

68-158° F

Oil Extractor Probes

(Total Qty = 5)

1/4” x 27-1/2” Long, Nylon

5/16” x 27-1/2” Long, Nylon

5/16” x 39-1/4” Long, Nylon

1/4” x 27-1/2” Copper

9/32” x 27-1/2” Copper

UNPACKING

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon

as possible.

REV 09h

Loading...

Loading...