6Ref. : CH - 1249 - A - 2

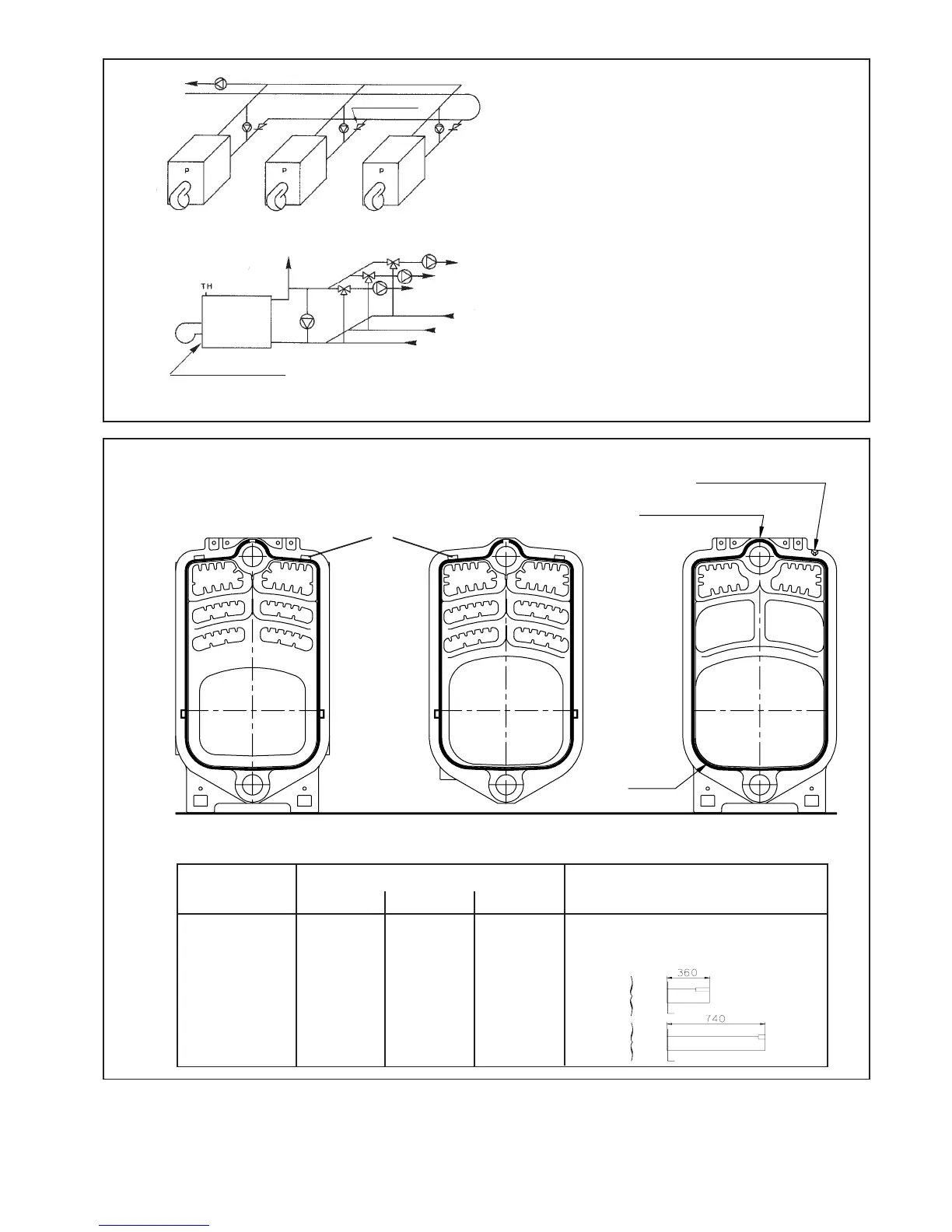

Boiler Number of sections

ref. Front Middle Rear

34 1 2 1 None

35 1 3 1 None

36 1 4 1 Short

37 1 5 1 Short

38 1 6 1 Long

39 1 7 1 Long

Distributors

Cord

S

S

E

Fig. 5

Sludge flush

Non return valve

Fig. 4

DIAGRAM OF THE ELEMENTS

S : tightening markings

E : spacing pads

S

Front Middle Rear

Assembly marking

Cord junction point

SSS

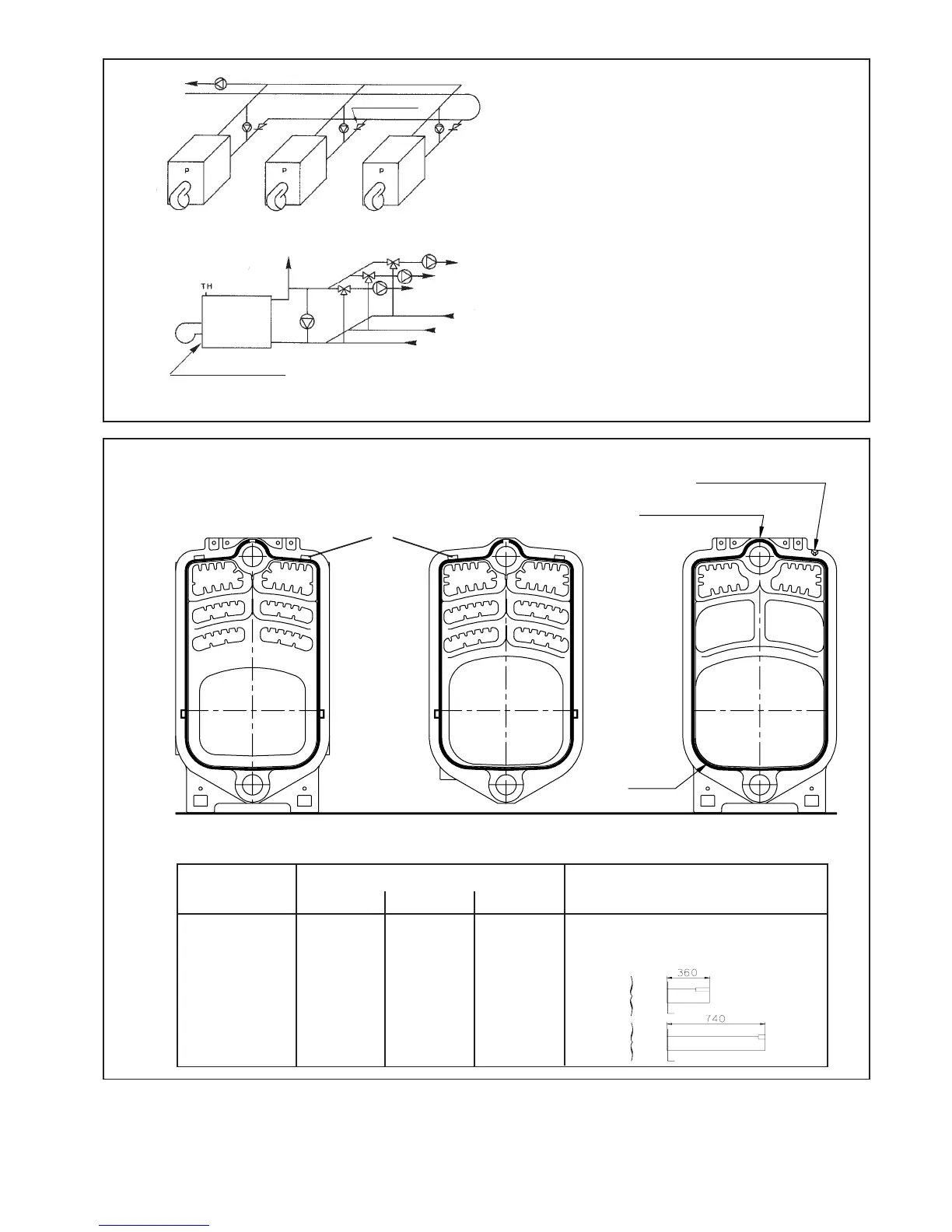

Minimum flow rate must be provided at all times,

whatever the rate of operation, either :

- by means of the main flow pump, provided that the

system has no mixing valve between each boiler and

the pump, and that the pump operates continuously,

- by means of a recycling pump or a loading pump

operating permanently.

In the case of a recycling pump or a loading pump per

boiler, and to avoid parasitic flows in the other boilers,

position non return valves upstream from the return

connection.

The burner must be controlled by the recycling or

loading pump. It can only be put in operation if the pump

operates. Secondarily, a flow control device, combined

with the TH thermostat, can be mounted on the return

of the boiler, downstream from the recycling or loading

pump.

To vents

00306N0225200.PLT

N0226701.PLT

Loading...

Loading...