5 Ref. : CH - 1249 - A - 2

3. ASSEMBLY AND INSTALLATION

Connections to water supply

Connection to the heating system needs to be done according

to statutory regulations and trade practice.

Fuel supply

For oil and gas, comply with statutory rules and

recommendations, in particular with respect to safety rules.

Power supply

comply with regulatory prescriptions, in particular with res-

pect to earthing and its connection to the boiler (main

switch...)

Flue stack

A 0 daPa depression should be observed at exit of smoke box.

Comply with statutory regulations and trade practice.

Please note that the efficiency of these boilers results in

relatively low flue gas temperatures.

Special care must be given to flue stack which must be air-

tight, heat-insulated and protected against degradation. One

of the actions to take is to line the duct. Tubing grade must

be compatible with the selected fuel.

It is advised :

• to keep the same cross-section as that of the boiler smoke

hood outlet,

• to avoid short radius,

• to keep the number of bends to a minimum

• where possible, to slope connecting parts upwards,

towards chimney

• to provide a purging vessel as close to the boiler as

possible.

Water flow rate

The system must be designed to ensure a water flow rate, in

each boiler, comprised between 1/3 and 3 times the QN

nominal flow rate.

QN =

Water flow rate allowed in each boiler must be comprised

between :

3 . 1 Boiler room layout

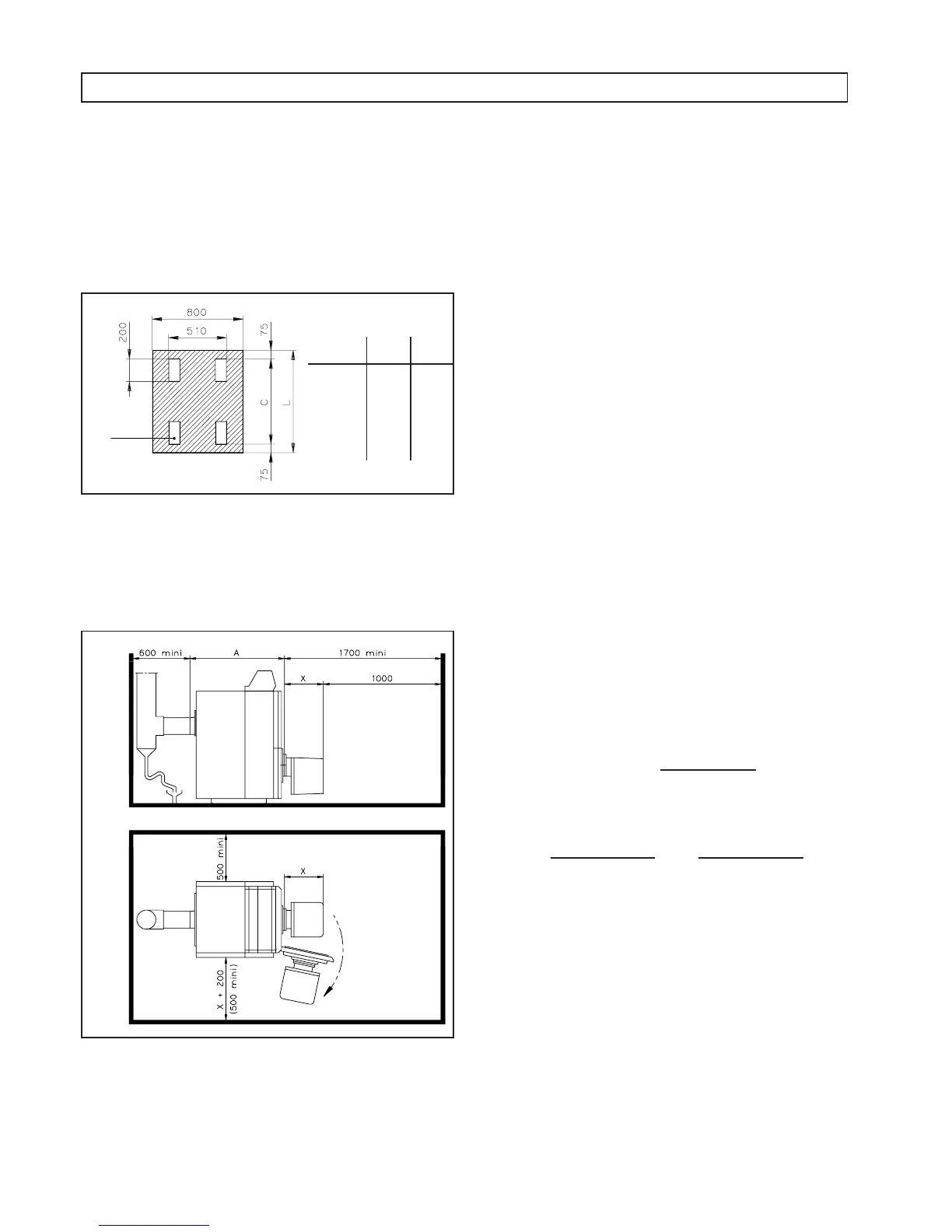

Plinth (see fig. 2)

No special plinth is required for this type of boiler. A simple dry

base suffices. For information, we provide the dimensions of

this dry base (figure 2). For certain special installations, a

sound-proof plinth may be necessary. We recommend a

metal plinth resting on reachable antivibration pads.

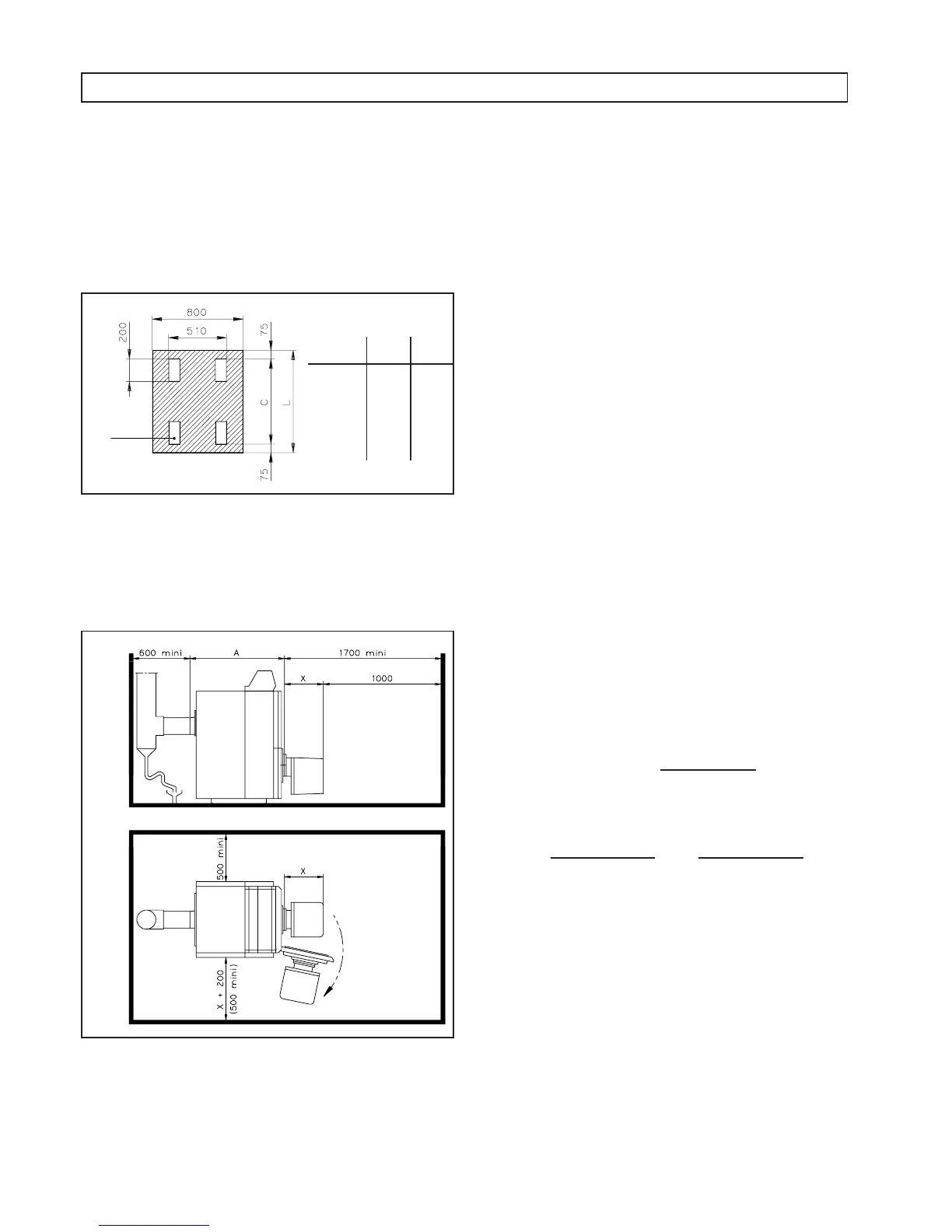

Fig. 3

Clearance (see fig.3)

The dimensions shown are minimal values which allow proper

access for assembly and maintenance operations.

No need to leave clearance above for cleaning purposes.

Boiler

size C L

34 750 900

35 920 1070

36 1090 1240

37 1260 1410

38 1430 1580

39 1600 1750

Flat bars

width 150

Optional

sealing

Fig. 2

Caution : assembly and installation must be carried out by a qualified engineer.

PN kW x 0,86

15K

PN kW x 0,86

5K

PN kW x 0,86

45K

and

N0225100.PLT

N0218601.PLT

Choice of burner

The burner should be chosen according to the boiler power

and furnace.

Ventilation

Comply with statutory regulations for low and high ventilation

Loading...

Loading...