1250E & 1500E Electric Pump

Operating Manual

CP/MAN-PRD-1215E REV. 02 EFF. DATE: 12/15/12 Page 5 of 13

3. PRIOR TO STARTUP – SAFETY CHECKS

3.1. Is the gearbox filled with suitable lubricant?

3.2. Is the power supply correctly matched to the motor?

3.3. Is the electric hookup of the pump correct and carried out according to all applicable codes?

3.4. Are all tubing/pipe connections made up correctly?

3.5. Is there a pressure relief valve on the discharge side?

3.6. Is the pressure relief valve operating correctly and is it set to the correct pressure?

4. CHECKING THE GEAR LUBRICANT LEVEL

CAUTION: THE PUMP GEARBOX MUST BE FILLED WITH GEAR LUBRICANT AT ALL TIMES

WHEN OPERATING THE PUMP TO AVOID RISK OF DAMAGE AND

OVERHEATING.

4.1. Oil level should be checked weekly.

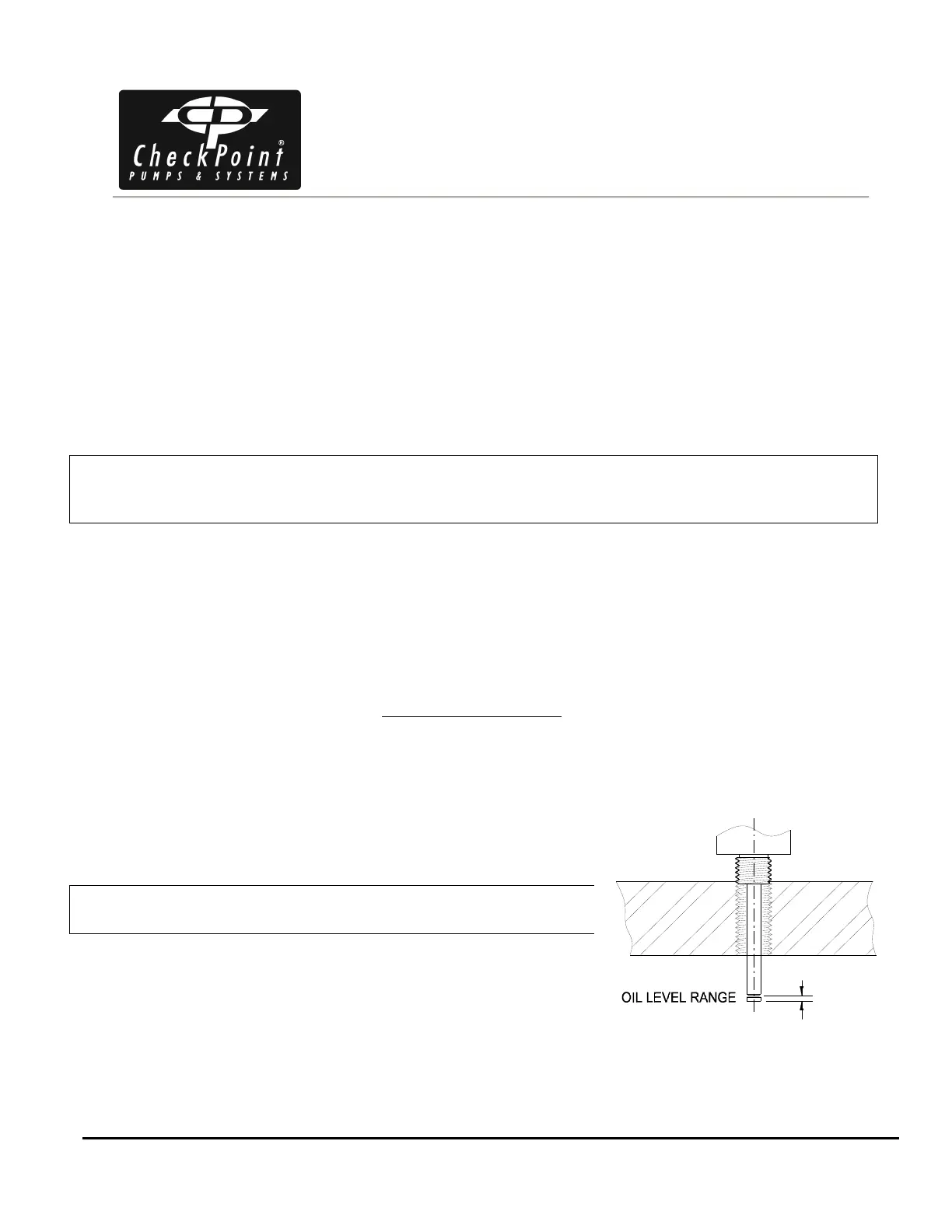

4.2. Use the Gear Oil Level Dipstick/Fill Plug (Item 10 in Figure 5 at the end of this Manual) to check

the level of lubricant as follows:

FIGURE 2

4.2.1. Stop pump and wait for approximately 5 minutes.

4.2.2. Unscrew cap, wipe dipstick with clean rag.

4.2.3. Put dipstick into hole, but do not screw it back in.

4.2.4. Oil level should be between the end of the dipstick and the middle of the groove.

4.2.5. Replace cap by screwing back in snugly.

5. GEAR LUBRICANT TYPE

5.1. Oil type for refilling and adding may be either synthetic or

mineral, but never both at the same time.

CAUTION: NEVER MIX SYNTHETIC AND MINERAL OIL IN

THE GEARBOX!

5.2. Mineral oil must conform to CLP 220 or ISO – L – CKC

220. Shell Omala 220, Mobil Gear 630, and Exxon

Spartan EP 220 are examples of mineral oils that are

acceptable.

5.3. Synthetic oil must conform to CLP PG 220 or ISO – L – CKS 220.

5.4. Mineral oil should be changed after each 4000 hours of use or one year of operation.

5.5. Synthetic oil should be changed after each 8000 hours of use or two years of operation.

Loading...

Loading...