E13

F: Communication 2 port (RS485 + RS422A)

+ External signal input 1 point *4

G: Communication 2 port (RS485 + RS485)

+ External signal input 1 point *4

P: External signal input 6 points *4

T: External signal output 6 points *4

U: External signal input 8 points *4

W: External signal output 8 points *4

Y: External signal input 3 points

+ External signal output 5 points *4

Z: External signal input 4 points

+ External signal output 4 points

⑫ Case color

G: Gray

B: Black

⑬

IP54 panel sealing specifications and terminal cover *

0: None

1: Terminal cover exists

2: IP54 panel sealing specifications + No terminal cover

3: IP54 panel sealing specifications

+ Terminal cover exists

⑭ Power voltage

A: 100 to 240V (AC)

D: 24V (AC/DC)

* Option

1): It can be selected when control mode (output number 1) is

1, 3, 5, or 6.

2): It can be selected when control mode (output number 1) or

control mode (output number 2) is 1 or 5 (pulse type).

Heater snapping wire alarm cannot overlap with other zones.

When output 1 and output 2 are both pulse type, alarm is judged

output 1 side.

3): It can be selected when zone 2 is 1, 2, 3, or 4.

4): It can be selected when zone 2 is 0, 1, 2, 3, 4, J, K, or L

Note: Common options of zone 1,2,3 are designated priority form

zone 3 ordering [9], [P], [M]

Setting the measuring range type

Refer to ‘Flowchart of key operations and displays’ on the next page

and make the setting.

Step 3. Setting example of input type (Refer to measuring

range table)

Press the MODE key on the operation screen to display the MODE

screen. Press the keys to display the MODE5 INPUT SET,

and then press the SEL key to display INPUT KIND. Press the

keys to select an Input type.

Press the ENT key to register the set contents.

Step 4. Setting the Program pattern

Press the MODE key on the operation screen to display the MODE

screen. Press the SEL key to set the program pattern.

Cleaning: Clean gently the front panel and keys of this instrument

with a soft moistened cloth (not too wet). Do not use a dry

cloth for cleaning the LCD display for risk of static

electricity. (If the LCD is accidently charged by static

electricity, the LCD will turn back to normal for several

minutes.) Do not use organic solvents such as alcohol.

See the following table for the obvious consumable parts used in the

instrument. Generally, most of the parts are subject to change or

degradation over time.

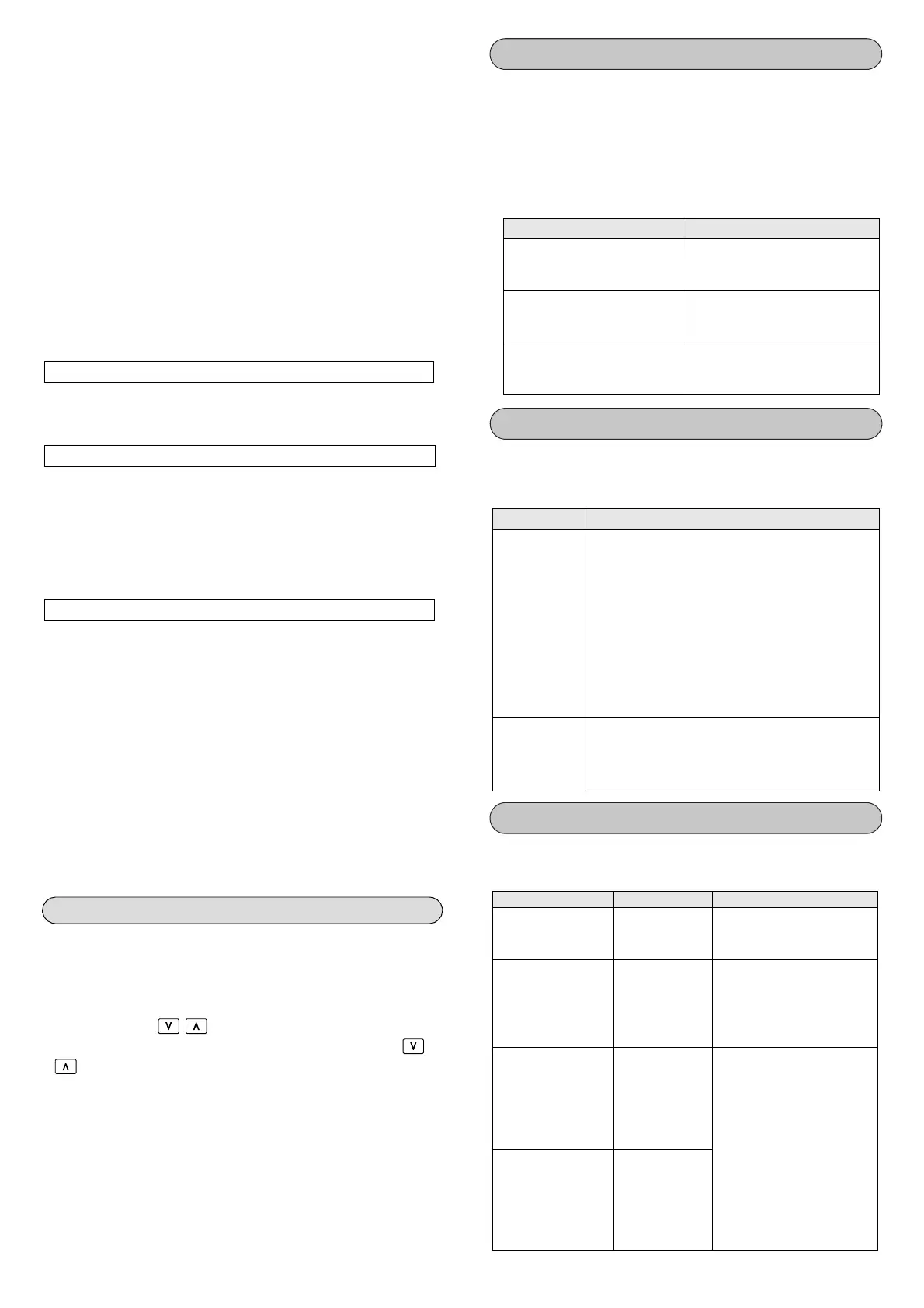

Part name Expected life

Relay

* Relay for control,

relay for alarm

Approximately one hundred

thousand times

Electrolysis condenser

* Condenser for smoothness of

electric circuit.

Approximately 5 years

(Surrounding temperature : 30

°

C,

operation time : 12 hours/day)

Battery (Lithium battery)

* Battery for memory backup.

Approximately 10 years

(Surrounding temperature : 30

°

C,

operation time : 12 hours/day)

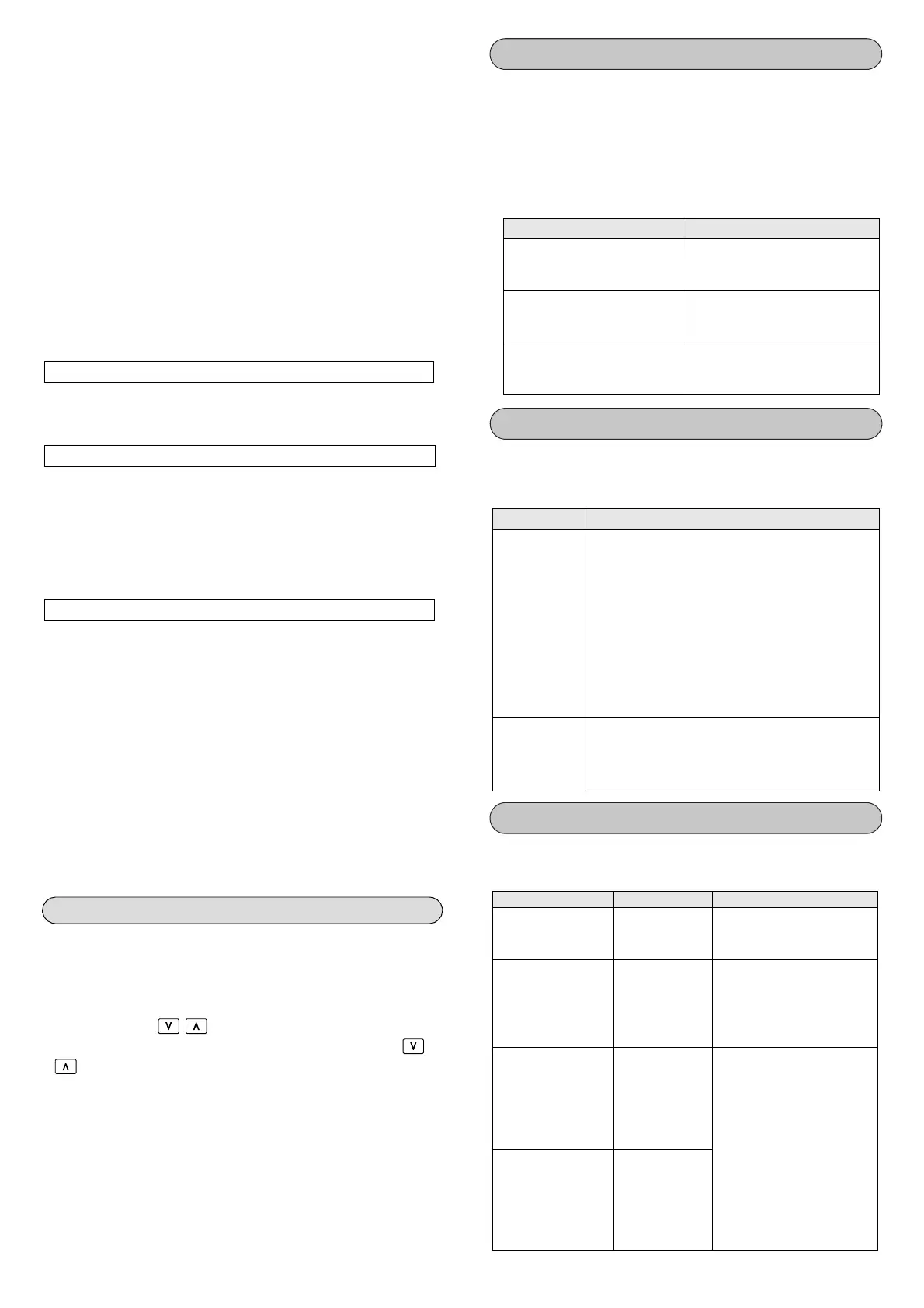

When an inappropriate setting or operation is performed, the

warning No. shown below will be displayed for approx. three

seconds. Check the warning contents and try appropriate setting or

operation.

Warning No. Warning contents

WARNING

No.10

KEY LOCK

・Setting is not changed because of the [Lock]

condition at the mode screen.

・Change the setting after canceling the

[Lock] condition.

・When a parameter is changed during a

writing process via communication, the key

lock becomes active temporarily to restrict the

key operation. To change a parameter by

keys, stop the writing process via

communication, and change the screen once

using the [SEL] key.

WARNING

No.61

TUNING FAIL

・The value of zero regulation of the servo

exceeds the value of span regulation.

・Make sure the open side and closed side

are wired correctly at feedback input.

When an error occurs in the system, the error No. shown below will be

displayed for approx. two seconds. Check the error contents and

contact the dealer or your nearest CHINO office.

Error No. Error contents Movement during error

SYSTEM ERROR

No.1 CALIBRATION

ERROR

Calibration data

abnormality

Normal operation continues

* 'Error' in the upper display is

not illuminated.

SYSTEM ERROR

No.6

AM BACK UP ERRO

Battery backup

abnormality

Normal operation continues

* 'Error' in the upper display is

not illuminated.

* The set contents of the

program pattern will be the

initial values.

SYSTEM ERROR

No.10

A/D COUNT : PV

Abnormality in

A/D conversion

for PV

'Error' in the upper display is

illuminated.

The measured value is fixed

at the indicated value when

an error occurs.

Control output:

PV abnormal output

(MODE4)

OUT1 ’ OVR’

OUT2 ‘0%’

Others:

Operation continues

SYSTEM ERROR

No.11

A/D COUNT : RJ

Abnormality in

A/D conversion

for RJ

Maintenance

Error display

Warning display

Loading...

Loading...