32

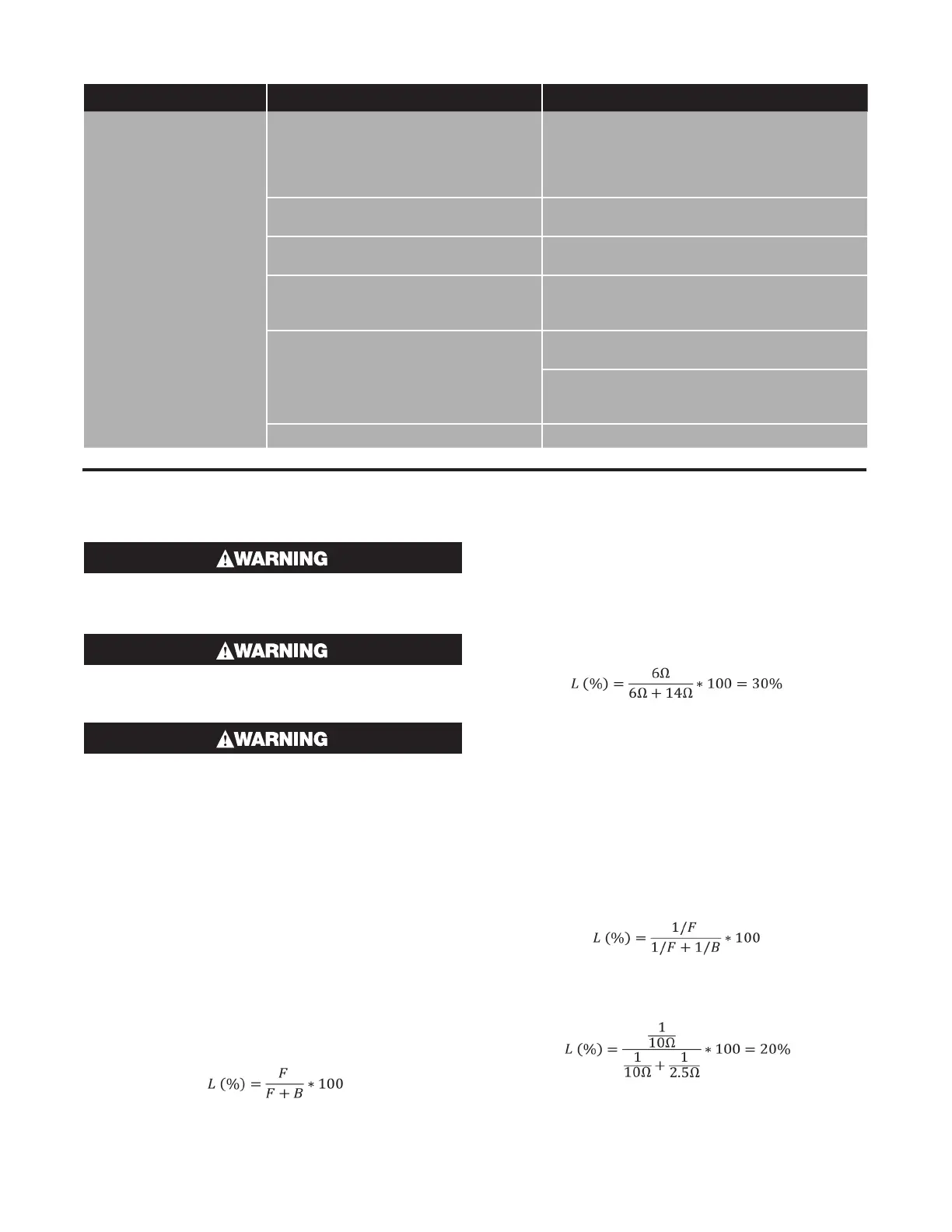

Observed Problem Potential Causes Corrective Actions

Circuit breaker trips

Undersized circuit breaker Check design to ensure startup temperature,

current loads, and maximum circuit length are not

exceeded, and that the power wire size is com-

patible with the circuit breaker. Replace circuit

breaker if necessary.

Startup temperature is too low Start up when temperature is higher than -76˚F

(-60˚C).

Damaged heating cable Replace damaged cable using the proper con-

nection kits.

Bus wires touching and shorting out Check for proper termination at end seal. Note

that the heating cable could be permanently dam-

aged and may need to be replaced.

Moisture Excessive moisture on heating cable core or bus

wires: Replace cable.

Moisture on connection kits: Retest after drying

out all components. Ensure all conduit entries are

properly sealed during reinstallation.

Undersized GFPD

Replace with appropriately sized GFPD.

Test Procedures

When testing any Chromalox heat trace product, al-

ways utilize the proper protective equipment and be

sure to comply with all applicable safety guidelines.

Before testing any Chromalox heat trace products,

ensure that all test equipment is working as intend-

ed and has been properly calibrated.

Only trained and qualified personnel should admin-

ister the test.

Locating Faults

The three most common test methods for finding the approx-

imate location of a fault in a heating cable are:

• Ratio test

• Conductance test

• Capacitance test

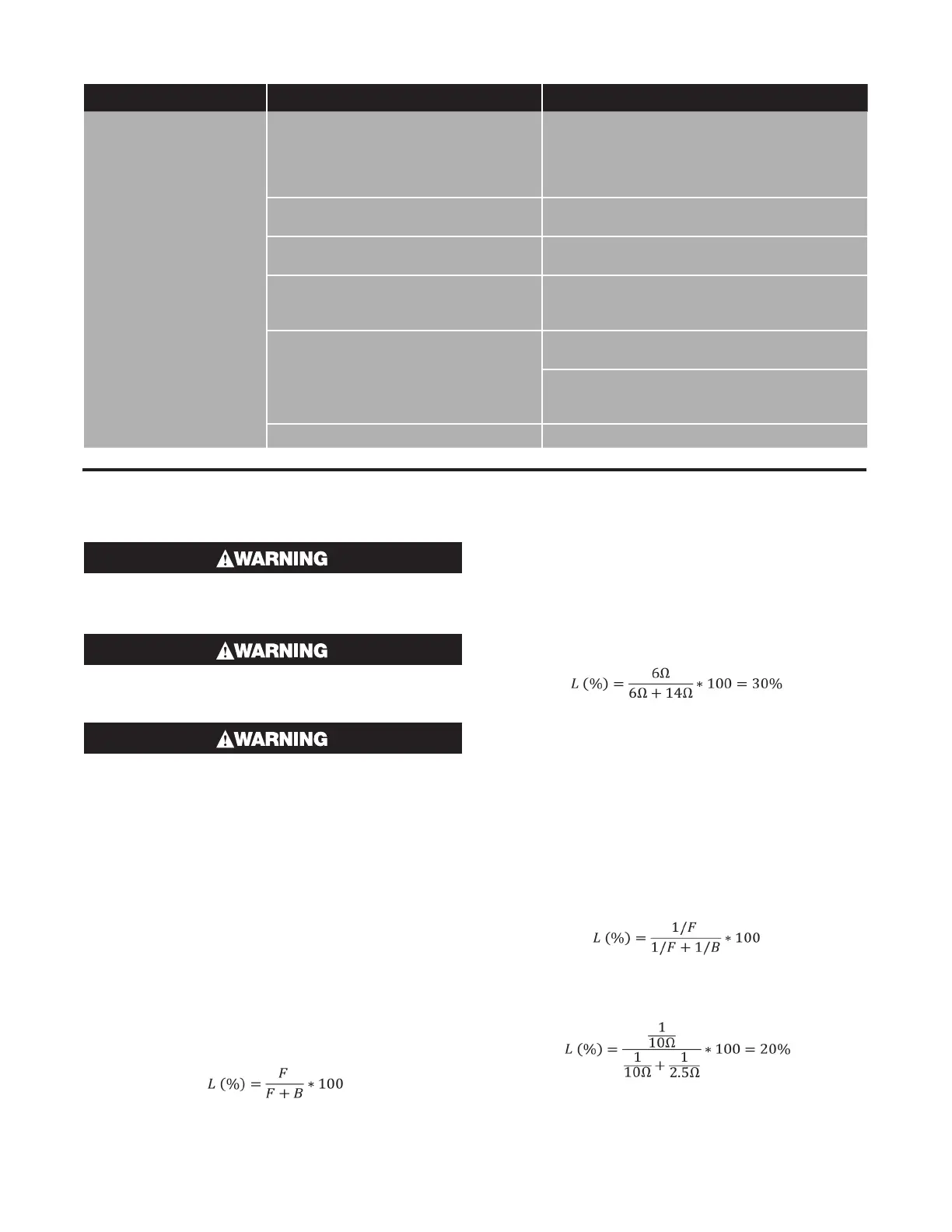

Ratio Test

The ratio test can be used to approximate the fault location

of a bus wire short or a fault from bus wire to ground braid. A

standard ohmmeter is used to take resistance readings from

both the front (F) and back (B) end of the cable. The fault lo-

cation (L) as a percentage of cable length measured from the

front end can be approximated by:

To determine a bus wire short, the resistance reading is taken

between the bus wires with one lead placed on each bus

wire. To determine a low resistance ground fault, the resis-

tance reading is taken between the bus wires and the braid

with one lead on bus wire and one on the braid.

Example: There is a bus wire short at an unknown point on

a 100ft cable. The resistance reading between the bus wires

is 6Ω from the front end of the cable and 14Ω from the back

end.

The bus wire short is approximated to be 30ft (30% of 100ft)

from the front end of the cable.

Conductance Test

The conductance test can be used to find the fault location

of a severed heating cable. A standard ohmmeter is used to

take resistance readings between the bus wires from both

the front (F) and back (B) end of the cable. The fault location

(L) as a percentage of cable length measured from the front

end can be approximated by:

Example: A 100 ft long heating cable is severed at an un-

known point. The bus-to-bus resistant reading is 10.0Ω from

the front end and 2.5Ω from the back end.

The cable is estimated to be severed at around 20ft (20% of

100ft) from the front of the cable.

Loading...

Loading...