TRANSPORT

THE MACHINE SHOULD BE ALWAYS TRANSPORTED IN VERTICAL POSITION

AND HAS TO BE LIFTED FROM THE BOTTOM CHASSIS BASEMENT ONLY.

ATTENTION

PLEASE AVOID TO HOLD, LIFT OR PULLING AND PUSHING THE MACHINE FROM ITS CENTRAL

CONSTRUCTION PART ( PLEXIGLASS MIXING BOWL, FLASK CHAMBER OR MAIN MOTOR SHAFT).

TECHNICAL DATA

VOLTAGE: 220 VOLTS - 50/60 HZ. SINGLEPHASE – CONSUMPTION: KW. 3.5

PROTECTION FUSE: 2 fuses x 16 AMP.

The fuses are located on the circuit board

MAX INVESTMENT DRY POWDER CAPACITY : kg. 6

ELECTRICAL POWER CONNECTION:

ATTENTION! THE UNIT MUST BE CONNECTED AND PLUGGED TO AN ELECTRICAL PLANT

WITH GROUND AND EARTH UNDER SAFETY SWITCH.

MACHINE ELECTRICAL COLOUR WIRING IDENTIFICATION:

YELLOW/GREEN:EARTH – GROUND BLUE: NEUTRAL BROWN: PHASE

VACUUM PUMP CONNECTION:

MIXER S. LOUIS 82 MUST OPERATES WITH A VACUUM PUMP CAPACITY 18 CBM/HOUR.

THE VACUUM PUMP IS SUPPLIED SEPARATELY AS INTEGRATED PART OF THE UNIT.

ON THE REAR PART OF THE MACHINE BASEMENT FIND THE VACUUM PIPE HOSE CONNECTOR

AND THE 220VOLTS PLUG ONLY FOR THE VACUUM PUMP. THE VACUUM POWER IS SUPPLIED

DIRECTLY FROM THE MIXER. DO NOT USE THIS PLUG FOR DIFFERENT PURPOSES.

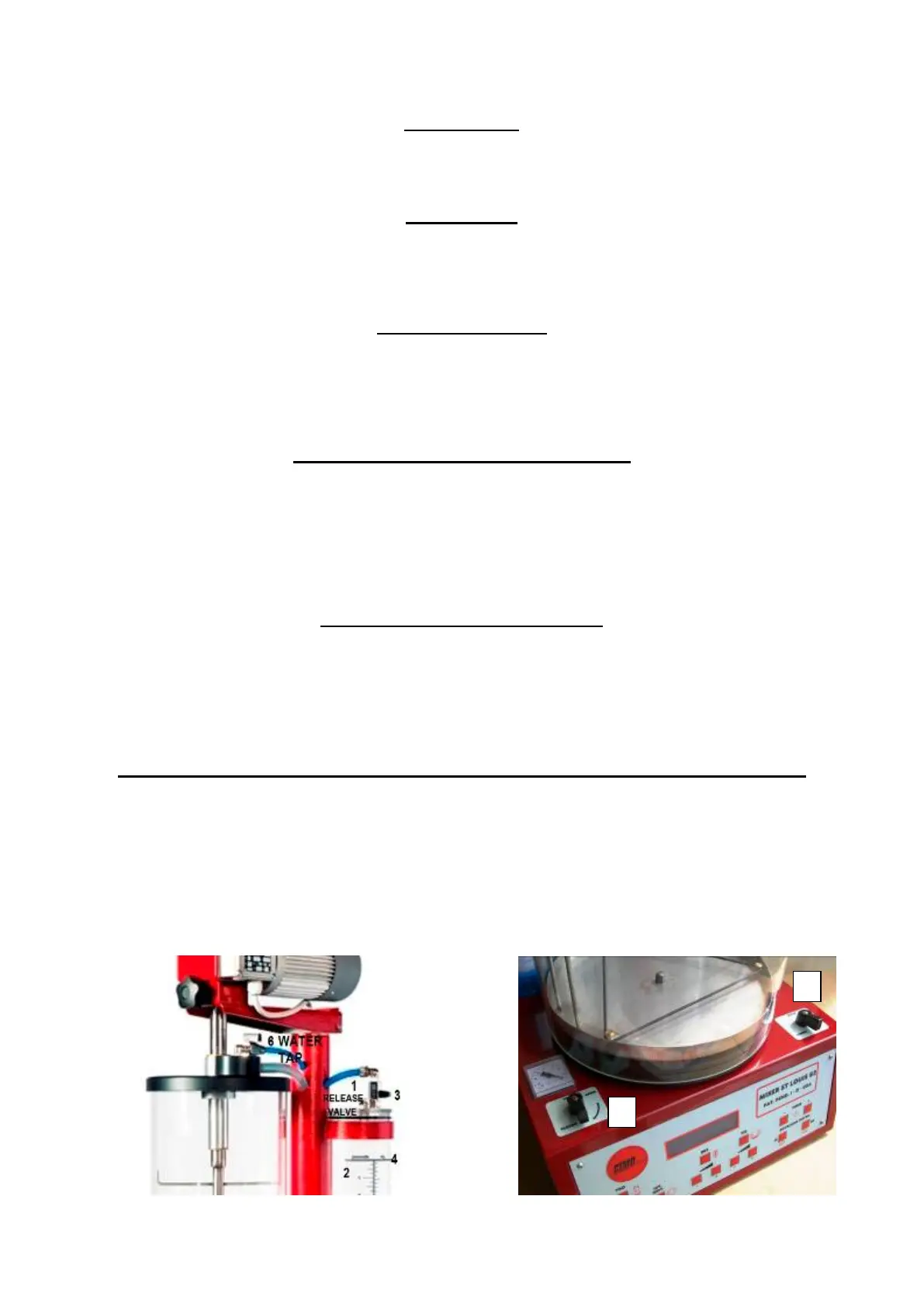

WATER SUPPLY CONNECTION: FROM THE MAIN FACTORY WATER PLANT

MIXER S. LOUIS IS PROVIDED BY A SPECIAL WATER PIPE WITH RELATIVE JOINTERS TO BE

CONNECTED TO STANDARD FACTORY-WORKSHOP TAPS. WE PROVIDE THE JOINTER SEALS TOO.

TO FILL THE MACHINE WATER DOSING TANK PROCEED AS FOLLOWS:

OPEN AIR RELEASE VALVE ( SEE PICTURE REF. 1 ) LOCATED ON WATER DOSING TANK ( REF. 2 )

CLOSE THE TAP (SEE PICTURE REF. 3 ) NEARBY THE VALVE ( REF 1 ).

OPEN THE MAIN WATER SUPPLY TAP OF THE FACTORY AND THE MACHINE WATER TAP ( REF. 4 )

FILL THE DOSING TANK UNTIL WATER LEVEL WILL REACH THE TOP LINE ( REF. 4 ) EXACTLY.

WHEN TOP LEVEL HAS BEEN REACHED, CLOSE AGAIN THE RELEASE VALVE ( REF. 1. )

Loading...

Loading...