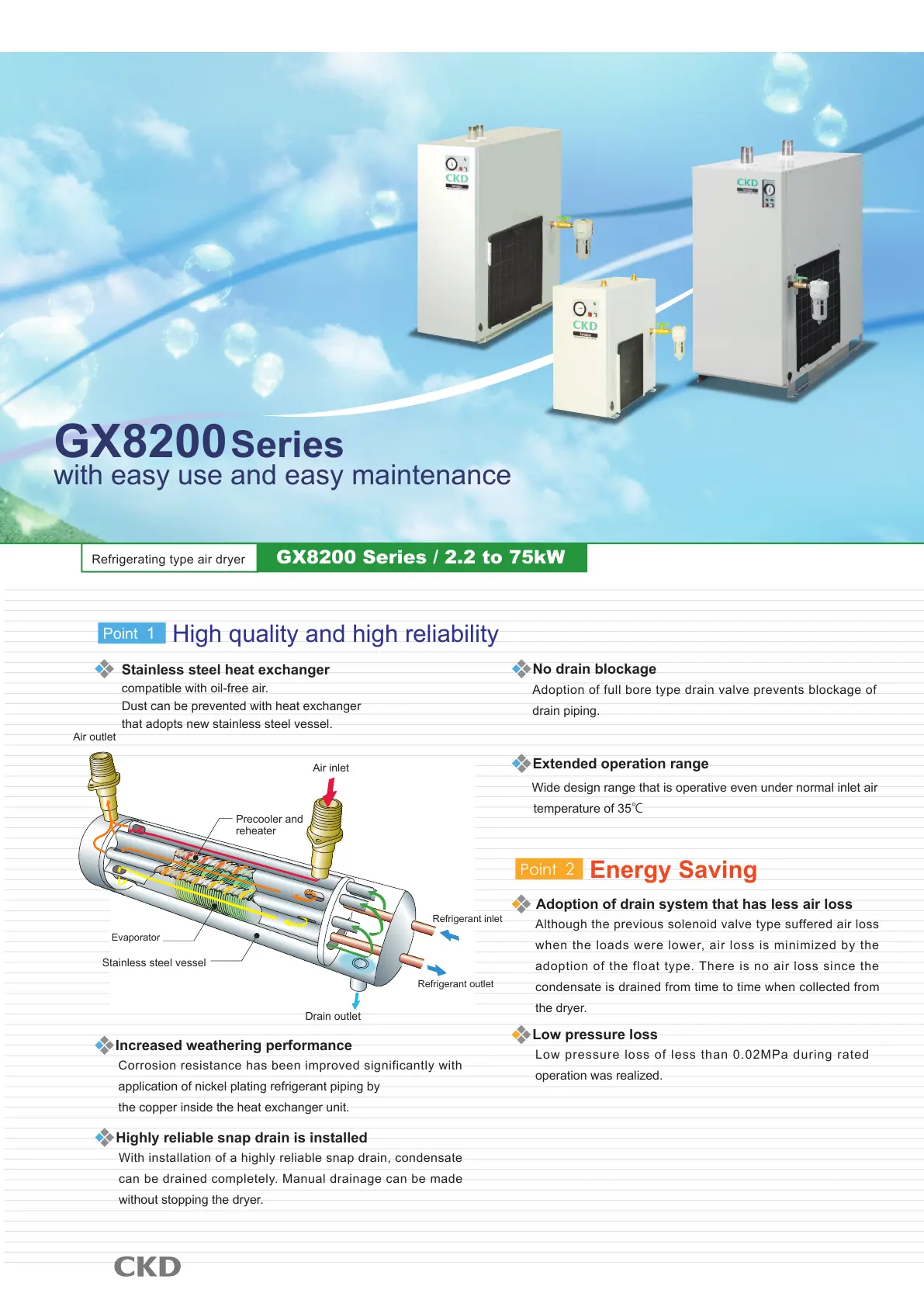

GX8200

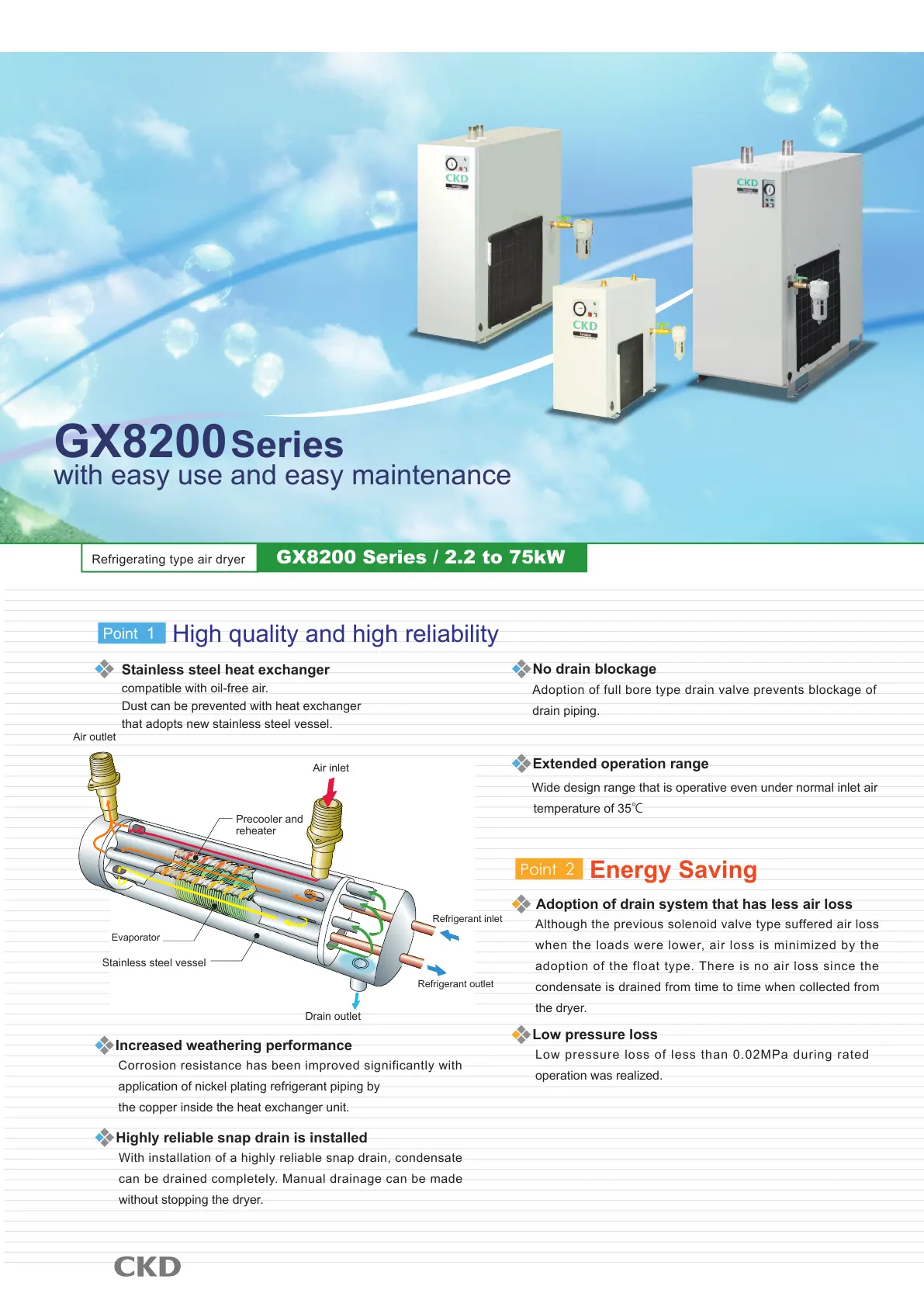

Stainless steel heat exchanger

compatible with oil-free air.

Dust can be prevented with heat exchanger

that adopts new stainless steel vessel.

Highly reliable snap drain is installed

With installation of a highly reliable snap drain, condensate

can be drained completely. Manual drainage can be made

without stopping the dryer.

Increased weathering performance

Corrosion resistance has been improved significantly with

application of nickel plating refrigerant piping by

the copper inside the heat exchanger unit.

High quality and high reliability

Point 1

Adoption of drain system that has less air loss

Although the previous solenoid valve type suffered air loss

when the loads were lower, air loss is minimized by the

adoption of the float type. There is no air loss since the

condensate is drained from time to time when collected from

the dryer.

Low pressure loss

Low pressure loss of less than 0.02MPa during rated

operation was realized.

Energy Saving

Point 2

Only look at the

operation panel for

checking.

Operating status can be

checked at a glance of

the refrigerant pressure gauge and

operating light.

External drain discharger

Drain discharger requires a daily check.

Easy maintenance without stopping the

dryer by the adoption of an external drain

discharger that requires a

dailycheck.

Dust filter equipped as standard

Dirt adhering to the dust filter can be

cleaned as that of an air conditioner.

Easy care and cleaning.

Enables central control in the factory

Easy maintenance

Point 4

R-134a, R-410A and R-407C

refrigerant are adopted

An environmentally friendly refrigerant

which does not destroy the ozone layer.

Eco friendly refrigerant

Point 3

GX8200 Series / 2.2 to 75kW

Refrigerating type air dryer

0

1

2

3

4

5

6

7

8

9

--

--

--

--

--

--

--

--

--

100

100,000

--

--

--

--

--

--

--

1

1,000

10,000

--

--

--

--

--

--

0

10

500

1,000

20,000

--

--

--

--

--

--

--

--

--

≦

5

≦

40

--

--

--

--

--

--

--

≦

5

≦

10

--

--

≦

-70

≦

-40

≦

-20

≦

+3

≦

+7

≦

+10

--

--

--

--

--

--

--

--

--

Cw

≦

0.5

0.5

<

Cw

≦

5

5

<

Cw

≦

10

≦

0.01

≦

0.1

≦

1

≦

5

--

--

--

--

--

Grade

Maximum number of particles per 1m

3

Solid particles Moisture and water content Oil

Particle diameter

d

(μm)

Particle

diameter

(μm)

Density

(mg/m

3

)

Pressure

dew point

(℃)

Water density

(Cw g/m

3

Total oil content

density

(

Mg/

m

3

)

d≦0.10

0.10<d≦0.5 0.5<d≦1.0 1.0<d≦5.0

Content has been revised in accordance with revision of JIS B 8392-1:2003 to JIS B 8392-1:2012

To be decided by the user and supplier applying conditions more severe than Grade 1.

[Compressed air quality grade JIS B 8392-1:2012]

※

Use corrosion resistant piping materials such as galvanized steel lining applied or stainless steel pipes. Install an air filter

just before the dryer depending on piping material if abnormal objects such as rust or peeling may arise inside the

piping.

※ Install an filter that removes contaminating substances inside piping just before installed equipment.

※ Note for oil Grade 1 : If the inlet oil paper exceeds 0.005mg/m

3

, install an X type filter additionally.

2.2

3.7

7.5

15

22

37

55

65

75

95

0.32

0.70

1.10

2.80

4.60

7.60

8.80

10.70

14.90

18.40

GX8203D

GX8204D

GX8208D

GX8215D

GX8222D

GX8237D

GX8255D

GX8265D

GX8275D

GX8295D

AF2004M-25

AF2007M-40

AF2010M-40

AF2010M-40

AF2013M-50

AF2020M-50

AF6027P-65

F3000-10-W-F1

F4000-15-W-F

F6000-25-W-F

AF2004P-25

AF2007P-40

AF2010P-40

AF2010P-40

AF2013P-50

AF2020P-50

AF6027P-65

M4000-15-W-X

M4000-15-W-X

M6000-25-W-X

AF2004X-25

AF2007X-40

AF2010X-40

AF2010X-40

AF2013X-50

AF2020X-50

AF6027P-65

M3000-10-W-F1S

M4000-15-W-F1S

M6000-25-W-F1S

M4000-15-W-F1

M4000-15-W-F1

M6000-25-W-F1

Air filter

(3μm or 5μm)

Micro alescer

(Oil removal)

Micro alescer

(High performance

oil removal)

Micro alescer

(for odor removal)

Refrigerating

type air dryer

Standard treated flow rate

Output

kW

m3/min

Air compressor

[Configuration of main line system (Inlet air temperature50℃, ambient temperature 35℃)]

Note : This system cannot be used for high pressure specifications (1.0 to 1.6MPa). Please consult with CKD.

2.2

7.5

15

22

37

55

65

70

90

120

0.44

0.97

2.31

3.48

6.16

8.71

11.54

12.55

18.30

25.39

GX8203D

GX8204D

GX8208D

GX8215D

GX8222D

GX8237D

GX8255D

GX8265D

GX8275D

GX8295D

AF2004M-25

AF2004M-25

AF2007M-40

AF2010M-40

AF2013M-50

AF2013M-50

AF6027M-65

AF6027M-65

F3000-10-W-F1

F6000-25-W-F

AF2004P-25

AF2004P-25

AF2007P-40

AF2010P-40

AF2013P-50

AF2013P-50

AF6027P-65

AF6027P-65

M4000-15-W-X

M6000-25-W-X

AF2004X-25

AF2004X-25

AF2007X-40

AF2010X-40

AF2013X-50

AF2013X-50

AF6027X-65

AF6027X-65

M6000-10-W-F1S

M6000-25-W-F1S

M4000-15-W-F1

M6000-25-W-F1

Air filter

(3μm or 5μm)

Micro alescer

(Oil removal)

Micro alescer

(High performance

oil removal)

Micro alescer

(for odor removal)

Refrigerating

type air dryer

Standard treated flow rate

Output

kW

m3/min

Air compressor

[Configuration of main line system (Inlet air temperature 35℃, ambient temperature 32℃)]

Note : This system cannot be used for high pressure specifications (1.0 to 1.6MPa). Please consult with CKD.

Air outlet

Precooler and

Evaporator

Stainless steel vessel

Air inlet

Refrigerant inlet

Refrigerant outlet

Drain outlet

GX8200 Series

with easy use and easy maintenance

No drain blockage

Adoption of full bore type drain valve prevents blockage of

drain piping.

Extended operation range

Wide design range that is operative even under normal inlet air

temperature of 35℃

Lubrication

type compressor

Filter P

GX8200

Refrigeration type

air dryer

Note

Lubrication type

screw air compressor

Lubrication type

reciprocating

air compressor

After cooler

Tank

Filter X

Filter X

Filter P

Branch line

Filter M

Filter P

Refrigeration type

air dryer

Small sized

heatless dryer

Oil Free type screw

air compressor

Turbo type

air compressor

Oil Free type

reciprocating

air compressor

After cooler

Tank

Branch line

Main lineMain line

Oil Free type

compressor

Filter X

Filter X

Filter X

Filter M

Filter MFilter P

Filter MFilter P

Filter MFilter P

Filter S

Large sized

heatless air dryer

Note :〔 〕Use X type filter in parenthesis when inlet oil vaper is 0.005mg/m3 at 21℃.

If not used, oil grade becomes “Grade 2”.

[Recommended Equipment Configuration]

Moisture removed air

Rough dust removed air

For civil and construction equipment

Air for cleaning that does not require drying

5μm

1μm

0.01μm

0.01μm

0.01μm

0.01μm

4

. --.--

3.6.3

3.5.3

2.6.1

2.5.1

2.6.1

2.5.1

2.3.1

2.2.1

2.2.1

2.3.1

2.2.1

2.2.1

Normal dried air

Odor free dried air

Super dried

oil free air

For instruments

For measurement

Sequence control

High quality painting

Food industry that does not blow air on

food directly

Pharmaceutical industry

For mixing, transportation, drying,

packing and brewing

Ozone generation devices

Powder conveying

Drying of furnace atmosphere gas

Drying of insulation gas for high voltage

generation units

Drying of computer rooms

For central control instruments

Super dried

odor free air

Food industry that does not blow air on

food directly

Pharmaceutical industry

For mixing, transportation, drying, packing

and brewing

Pressure

dew point

10℃

Pressure

dew point

7℃

Pressure

dew point

10℃

Pressure

dew point

7℃

Pressure

dew point

10℃

Pressure

dew point

7℃

Pressure

dew point

-20℃

Pressure

dew point

-40℃

Pressure

dew point

-60℃

Pressure

dew point

-20℃

Pressure

dew point

-40℃

Pressure

dew point

60℃

0.6mg/m

3

0.01mg/m

3

0.003mg/m

3

0.01mg/m

3

0.003mg/m

3

[0.003mg/m

3

]

Solid molecule

Moisture Oil content

Air quality Application Grade

Impurities in the air

SHD series

HD series

SDM series

Filter P

Polymer membrane

type air dryer

Normal pressure equipment

Normal pressure tools

Power saving equipment

Jigs and tools using air

Air chuck

Air vice

Cleaning air for precision parts

Oil free dried air

For example “Grade 2.2.1” means

●100,000 solid particles of 0.1 to 0.5μm ●Pressure dew point of -40℃ or less ●Oil density of 0.01mg/m

3

or less.

)

Remotecontrol,operation,andalarmoutput

functionsareinstalledasstandardinmodels

GX8265andGX8275.

reheater

Loading...

Loading...